Drivers of Change

Is your metal finishing software ready for an upgrade?

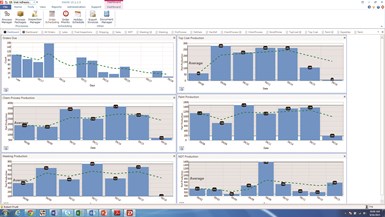

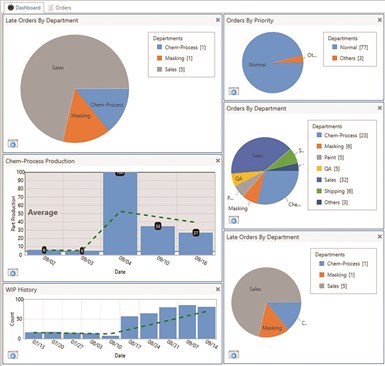

A customizable dashboard is a series of graphs and charts that provide an easy way to visualize past data points and current information.

No matter what type of metal finishing, processing, or plating being performed, at some point every organization will all faced with the question, “Is it time to change our software, or should we continue with our current system?” This is not a quick or easy decision to make. Choosing to maintain the current system presents risks falling behind the competition and industry, losing product support, and limiting the features available today for both employees and customers. On the other hand, if the decision is made to change software, a large investment will be incurred, as well as a certain amount of risk including undergoing varying degrees of disruption to the organization, costly production down-time, and the possibility of a failed implementation.

What is the right answer? Each process of evaluating this question will be unique to the organization, but there are several features and processes to look for depending on the situation and type of processes and accreditations are performed and maintained.

Be Prepared

Do the Research. Before beginning the search for a software system, take steps to ensure all requirements are met. A phrase commonly heard when discussing a software replacement is, “There is never a good time for an Implementation”. Due to the fast-paced nature of the Finishing industry, there are few opportunities to completely stop operations and implement new software, and possibly workflow routines. Software research, planning, purchase, and implementation will likely be performed alongside day-to-day operations. Because of this, a well-planned, methodic directive and 100 percent commitment from the Implementation team will greatly reduce chances of costly delays or a failed implementation.

Requirements. Begin by creating a spreadsheet, listing requirements for the new software system. Challenge users to create lists of current software headaches and feature wish lists. Reach out to Users from multiple facets of the company. Often, work-arounds, sticky notes, or tribal knowledge may be playing a more important role in processing than is immediately visible to the executive team.

Licensing and Price Point. Software licensing comes in many forms. Software may be priced by user, concurrent user, or computer system (seat). Also, are the included features clearly advertised, or will there be an upsell for additional modules or capabilities? Is Implementation included? Does the quoted price include updates and new releases and support? While researching, it is imperative to find a software system priced to meet the company’s current needs and workflow but contains flexibility for potential growth and can scale to meet those needs.

Recommendations and Sustainability. A seasoned software firm should be able to provide company history, verifiable customer recommendations, and on-site demos with existing users. Seeing an application running live in a production environment is monumental in determining the efficiency after implementation. Ensure the firm provides contractual verbiage, or source code escrow to ensure a sustainable product in the even of bankruptcy or becoming insolvent. Speaking with current customers can provide no-nonsense information on implementation and go-live timelines as well as post-sale support insights.

Implementation and Training. What kind of training comes with the software purchase? Pre-training, onsite, online, follow-up? These are questions to ask the software provider before the purchase. Some companies offer remote installation and online training, while others prefer to accomplish both on-site. When purchasing or upgrading software, support after the sale is as important as the software itself. Become familiar with the exact terms of the sales contract. Software companies should also be able to provide access to an online library containing how-to articles, videos, and presentations for use at the user’s discretion. Some companies also utilize a help desk feature or support hotline for the not-so-frequently asked questions.

Releases, Bugs and Support. Is the software regularly updated, improved, and are new versions of the product released? Some programs may be complete out of the box while others may be in a state of continuous development. Ideally, new features should grow and improve with market trends, as well as fluctuate with the necessity of the User. Therefore, it is important to choose a company that is diligent about improving the product and striving to meet customer needs. The software provider should produce scheduled updates and releases to ensure the most up to date product is being utilized. Any bugs or errors from previous versions should be identified and corrected. A software company may also maintain an online forum to express customer feedback or ideas for improvement. There should be a direct relationship between the needs of the customer and the content developed in software releases.

Development Platform, Framework and Procedure. Similar to building a finishing process and performing a service to a part, software development requires a great deal of knowledge, best practice, training, and tools. Find a firm that develops their platform on an easy-to-use, widely available platform like Microsoft. A product is only as good as the sustainability and support of the development platform and language. A software provider should also provide detail about development framework and methodology. Framework techniques like Scrum or Waterfall are common development and software project management practices utilized by most leading developers. Feature testing types and procedures should also be inquired upon to ensure bugs, defects, or security risks are not present in the application.

Features and Capabilities

The new software system should meet immediate needs while allowing for Enterprise-level growth in the future. A comprehensive, modern, software system should incorporate the following features:

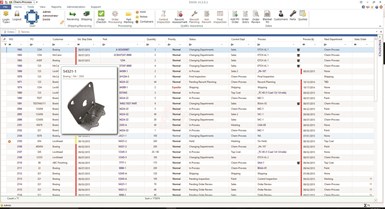

Real-Time Data. A work in progress or WIP screen will easily track where all in-house orders are located for complete situational awareness, with a fully functional and customizable WIP screen. This can be used to quickly sort, track, filter, and organize all work orders while in process. Whether being used at a management level or by users on the shop floor, a comprehensive live-data screen can become one of the most commonly used and valuable tools in any work order management system.

Paperless Processing. One of the most recent trends in manufacturing is paperless processing. Reducing the number of hard copies of drawings, specifications, data sheets, and purchase orders that travel with a job will reduce clutter and eliminate the possibility of losing or accidentally switching important documents. Using digital copies of specifications also ensures that the most current revision of a part or process is always in use. Paperless processing gives users the ability to answer any specification or inspection questions digitally to ensure completion and validity.

Batch Processing. Batching allows users to group like orders by process, which allows multiple orders and parts to be processed at the same time. This allows operators to enter any processing data only once for all orders in the batch while maintaining part and order traceability. It is a common scenario for customers to use batching by placing the optimal number of parts on flight bars or fixtures as they are processed throughout the plant. The option to batch orders while still accurately recording all data points can streamline almost any type of finishing process.

Mobile Processing. The ability to track, view, and process orders using a mobile phone or tablet application is a new option offered by select finishing software systems that takes paperless processing to an unprecedented level. During common shop workflows, it is not always convenient to leave the work area to enter data at a kiosk or some functions might be better suited to mobile users. Common scenarios are quality inspectors roaming the shop floor ensuring quality is met in every department or carrying a tablet while processing orders on a crane. The lower cost and higher mobility of tablets makes Mobile Processing an up-and-coming trend, likely to expand to most manufacturing software.

Barcoding. The use of barcode scanners to track, check-in, and process work orders can save valuable time previously spent hovering over a keyboard, entering jobs in manually. The ability to process an order or identify location are paramount to maintaining traceability and ensuring orders are processed or inspected in the correct departments. Many software systems incorporate customized travelers or labels that contain processing, shipping, or company information via barcoding. When selecting a software product, ensure that all necessary barcoding languages are available in the new application.

Document Management. Along with workflow and employee management, another desirable attribute is a single repository for storing, scanning, and importing all process-related documents. A comprehensive document manager included and driven by the new software system will save the time and confusion caused by lost documents, and allow employees to reference any specification, work instruction, purchase order, or job-related note at any point throughout the shop. They should be able to access documents via mobile or desktop, during processing, inspecting, or during any other process of an order. Ensure the document management system is secure, backed up, and provides revision control to keep the company in-line with the toughest quality control system. An included, comprehensive document management system can often eliminate the need for a third-party document management application.

Quality Management. Along with workflow and employee management, another desirable attribute is a single repository for storing, scanning, and importing all process-related documents. A comprehensive document manager included and driven by the new software system will save the time and confusion caused by lost documents, and allow employees to reference any specification, work instruction, purchase order, or job-related note at any point throughout the shop. They should be able to access documents via mobile or desktop, during processing, inspecting, or during any other process of an order. Ensure the document management system is secure, backed up, and provides revision control to keep the company in-line with the toughest quality control system. An included, comprehensive document management system can often eliminate the need for a third-party document management application.

Rework Management. Although 100 percent first-pass yield is the industry goal, no shop processes perfectly all the time. As such, rework planning, including internal, external (RMA), and part quarantine, is extremely important when maintaining accreditation compliance and work order traceability. Work order management software should allow users to manage and track any type of rework. In addition, rework tracking and reports can be extremely useful for isolating root causes and generating corrective actions.

Job quoting. The ability to quote and plan jobs from one all-inclusive platform can be a time-saving asset for any finishing facility. An integrated quote manager can help make sure all quotes are being generated from the same guidelines and include accurate metrics and relate any order all the way back to the original quote that generated it. This feature should also ensure that all quotes are accurate and consistent regardless of when, or by whom, they are created.

A dashboard can be a quick guide to quality issues, tracking production and workflow, and finding bottlenecks on the shop floor.

Dashboard. A dashboard is a series of graphs and charts that provide an easy way to visualize past data points and current information from the WIP screen. A dashboard can be a quick guide to quality issues, tracking production and workflow that helps identify bottlenecks on the shop floor.

Scheduling. Scheduling in the finishing industry has, until recently, been a common roadblock. With multiple customers, departments, processes, and turn times, scheduling shop flow can present a complex problem with several possible ways of resolving the issue. A scheduling solution should have the ability to create a schedule based on process, production time, or shop load capacity. The ability to turn this schedule into visual media (charts or graphs), as well as sorting by department, process, or user, makes a scheduling tool useful for management as well as employees on the shop floor. The key is to keep scheduling simple yet effective.

Shipping Integration. What good is a modern, streamlined process if the parts never reach the customer? The shipping department in a finishing facility can easily become a traffic jam or opportunity for communication failure. Integrating the shipping department into the software system can eliminate these issues. Shipping integration can capture and validate shipping information and tracking numbers digitally. Integrating this function into a software system also helps ensure that the correct order shipsto the correct customer via the correct shipping method. In addition, the system should provide automated shipping notifications that can drastically reduce the amount of “Where are my parts?” calls and emails. Users should possess the ability to automatically print customer-specific shipping labels, package labels, and packing lists, that will save time, accurately identify orders, and ensure shipping accuracy.

Traceability, Reporting and Historical Data. Does this software provide the traceability, reporting, and historical data needed and required? In the NADCAP world of finishing, traceability and historical data are crucial elements in maintaining accreditation. The selected software should provide users with as much, or as little, reporting and traceability as required. Remember, what can be proven is as important as what can be produced. If operating multiple processes and production lines, reporting plays a key role in keeping track of production. Ideally, the new software should be capable of producing real-time reports, charts, and graphs based on multiple fields of data. Examples would be order count by department, department production rates, current backlog, WIP (work in progress), late orders, production schedules, and many others. The ability to print work order travelers, tags, and labels (including a part number, description, and picture) allows for traceability to be maintained throughout processing.

Accounting. The ability to integrate existing accounting systems with the new finishing software is another key step towards streamlining business practices. In most cases, the software system will provide an accounting setup tool to assist in the initial integration and syncing of existing data. Some work order systems provide include a built-in accounting system. Another solution is to integrate with existing commercial accounting systems, which provide the best of both worlds, a proven accounting system that all accountants and CPAs already know, and a work order management system that seamlessly integrates with it.

Customer Portal. An interactive customer portal will allow customers to check the status and ship date of their orders through a customer-unique online experience. This unprecedented level of transparency will reduce order status calls and emails and provide customers with the added confidence of knowing exactly when an order will be completed. This will allow customers to proactively get updates on current orders, see the history, and address any issues before they escalate.

Customer Notifications. Daily customer status reports are another innovative and time saving feature among finishing software solutions. Users should be granted the ability to send customer notifications, tailored to each customer. While some customers want to receive shipping notifications, receipt notifications, status updates or more, others may choose to opt out completely. Keeping the customer informed will help increase trust through transparency, reduce frustration, and help develop a stronger relationship.

Ease of Use. New finishing software systems can quickly become obsolete if they are difficult to incorporate, learn, and operate. Software should not only be powerful and comprehensive but also simplistic and concise. It should provide a modern, user-friendly experience from initial setup, to quoting and planning, all the way through processing and shipping.

Ultimately, the decision about a new software system and provider will be based on each company’s individual needs, now and in the future. Choose a software provider focused on combined success with a prosperous future, rather than just a sale.

Related Content

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

Read MoreSolvent Versus Aqueous: Busting the Myths

Is aqueous cleaning “greener” than solvent cleaning? Is solvent a more effective cleaner than aqueous? These and many other questions are answered here to debunk the misconceptions that many manufacturers have held onto for years.

Read MoreHow to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreInstalling an Ecoat Line

Thinking of investing in electrocoating capabilities? George Lovell, coatings plant manager for Lippert, discusses considerations you should keep in mind as you add your ecoat line.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More