Electroplating for Medical Devices

Brittany McKinney of Pavco Inc. discusses the benefits of electroplating for medical devices.

Q: The medical devices I see at the doctor’s office look like steel. What keeps them from rusting?

A: Steel is a metal that is used in many different industries worldwide. Steel can easily be stamped, welded, carved into various shapes depending on the type of part needed in the industry. Steel without any type of coating can be less durable, and prone to corrosion in many different environments. Electroplating can help strengthen the steel part as well as protect it from factors that cause corrosion. The process of electroplating is what keeps medical equipment from rusting.

Electroplating is a process in which electrodeposition is used to coat metal(s) onto a part. The part being coated is the cathode, which is submerged in electrolytic solution with an anode and electric current is applied. The cathode in this case would be a medical device. The electric current causes anions to move to the anode (various types of anodes depending on the coating being applied) and for cations to move to the cathode, coating the medical devices in the metal desired.

Electroplating steel can help strengthen the material. The coated metal on the steel can increase the tensile strength of the part, allowing the lifespan of the part to increase. The coating adds a protective shield to the steel base of the part. This prevents the part from being damaged as easily during use or if dropped or hit against another part. If the steel is brittle in nature, the coating helps protect the brittleness of the part. The electroplated coating will dissolve before the steel will, increasing the lifespan of the part being used. Medical devices need to be able to endure the stress of being used daily. Some medical devices are needed for high-strength procedures. The coatings work to support the base material. Having electroplated coatings on medical devices increases the durability and life span of the tools.

Electroplating also helps prevent steel parts from corroding. Medical devices are often used repeatedly. Between uses, the devices are cleaned thoroughly and aggressively. The repeated use and cleaning of the medical devices could lead to corrosion without the presence of electroplated coatings. The type of coating will depend on how much the part will be exposed to corrosive elements. This reduces the number of times a part needs to be changed out or replaced due to rust forming. Corrosion also attacks the integrity of the steel, allowing it to break down and become much more brittle over time.

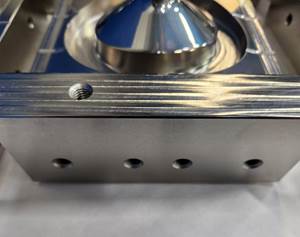

Throughout history, precious metals were normally coated onto medical devices. Improvements in technology and electroplating manufacturing have given various other coating options for medical devices, such as decorative electroplating. Decorative electroplated coatings not only protect the steel from corrosion and damage but create a cosmetically appealing coating. Decorative coatings that are applied to medical devices are nickel and either hexavalent chromium or trivalent chromium.

Electroplating on steel is a must to ensure the quality, strength, and lifespan of the parts used. No one wants to go to a doctor to have a procedure done and see rusty medical devices in the office. Without any coating, medical devices have a higher risk of becoming brittle, corroding, and unable to withstand frequent use.

About the Author

Brittany McKinney

Brittany McKinney is a Technical Service Engineer at Pavco, Inc. Visit pavco.com.

Related Content

Top Shop Builds Original Systems for Coating Medical Devices

Engineers at Surgical Coatings in Colorado have been ingeniously developing their own equipment, automation, processes and software since this powder coater’s inception in 1995.

Read MoreEngineered Coatings Offer Improvement for Medical Device Manufacturers

Diamond electroless nickel coating provides better lubricity and improved wear resistance for molds, resulting in better quality and productivity.

Read MorePrecision Coating Receives ISO 14001 Certification

The company says its commitment to the environment and its health led it to seek this certification.

Read MoreFinishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;maxWidth=300;quality=90)