Finishing Index Lower as Finisher Reduce Backlogs

November Finishing Index: 50.8

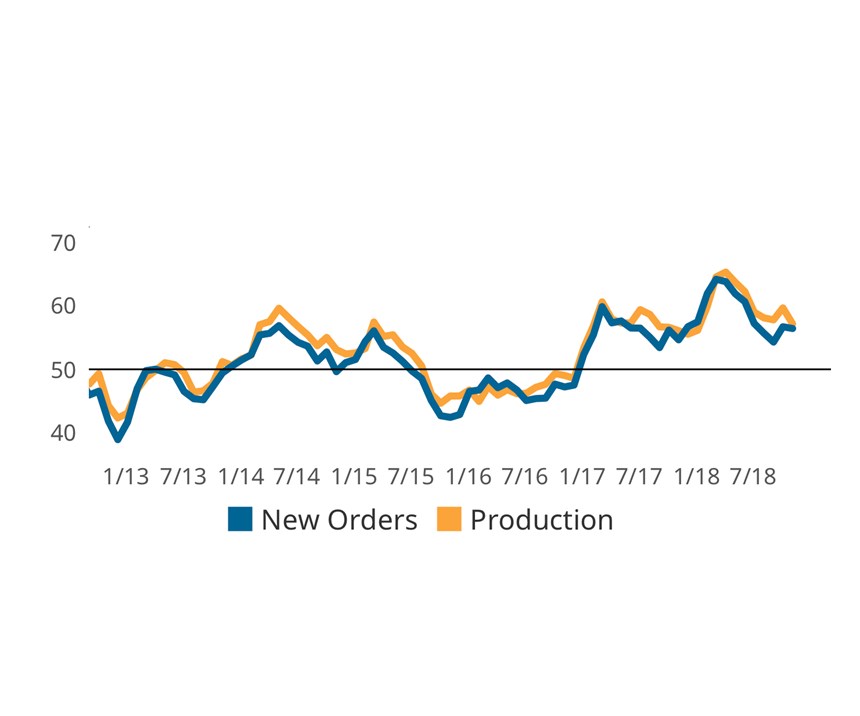

The Finishing Index registered 50.8 for November, suggesting only a slight expansion in the industry. Most of the Index’s components expanded more slowly, relative to the prior month. Compared to the same month one year ago, the Index is 1.3 percent lower, resulting primarily from a lower employment reading. In the latest period, the Index was supported by supplier deliveries, new orders and production. The components which pulled the averages-based index lower included exports, backlogs and employment. All three of these components signaled contraction during the month.

For a seventh consecutive month supplier deliveries have been the fastest expanding component of the Index. The average supplier delivery reading in the year-to-date period at 61.8 is nearly fivepoints higher than the prior record average set in 2017. The significant expansion of the finishing industry’s supply chain in 2018 likely explains why backlogs have reported slowing and even contracting in the second-half of the year. Due to how the Finishing Index is calculated, as the industry’s supply chain expands and increases the Index’s reading, it also allows finishers to reduce their backlogs which results in downward pressure on the Index. For this reason, slowing or even contracting backlogs may indicate that the industry is merely equalizing the balance between capacity and new and pre-existing orders.

Related Content

-

Cobot Enters Paint Industry With Safety at the Forefront

This collaborative robot is the first explosion-proof solution for the powder coating and paint arena that meets the U.S.’ stringent safety requirements. Its lead-through teach programming and tablet control are especially appealing to small shops with little proficiency in robotics.

-

Robots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

-

Concrete Reinforced Bars Built to Last

Not all corrosion-resistant materials for infrastructure are created equally. Epoxy-coated steel rebar has advantages that other materials used to prevent corrosion do not.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)