How to Limit Rack Twisting in a Coating Line

Mighty Hook’s Scott Rempala offers some suggestions for minimizing rack twisting in a coating line.

Q: Our team believes that we typically have good rack density, but the racks sometimes twist a little in on our coating line, which creates coverage problems. Can you suggest how we might limit this problem?

A: The issue you are describing is not uncommon. Rack tracking, as our engineering team likes to call it, is as important to coating quality and efficiency as rack density. For this discussion, I will use the term “tracking,” as the same concepts apply whether you are using a rack, hook or other hanging method. Tracking is an essential element of part presentation, which is the method of presenting the part to the coating equipment, where it will receive the maximum uniform coverage on critical surfaces without pooling pretreatment solutions or accumulating debris. Additionally, proper tracking will improve pretreatment quality and reduce the possibility of “hang-ups” or crashes in your system due to out-of-plane hangers contacting elements of the coating operation.

According to most equipment suppliers, your parts should be equal to or less than 5 degrees parallel to the guns, if coating with automatic guns or robotic sprayers. This can be difficult to accomplish if your hangers are not consistently presenting the part due to instability of the hanger-to-line attachment. Swaying or twisting of the hanger through the coating booth can also present challenges to manual sprayers, as they will have to constantly adjust to inconsistent part patterns.

With that said, there are a number of ways to accomplish better hanger tracking through your conveyor system. The simplest way to improve tracking or eliminate twisting is to double hang or attach the hanger to two independent points on the conveyor, which effectively creates a “wheelbase” and provides stable part transfer.

If double hanging has been discussed but is not feasible due to inclines and declines on your conveyor, the next option may be to add a stabilizer to the top of the hanger (see Figure 1). A stabilizer is typically a short section of wire or flat-stock steel that is welded to a certain point on the hanger top that abuts to the conveyor attachment, be it a pendant, trolley attachment or load bar. When positioned and designed correctly, the stabilizer will eliminate hanger twisting and lateral movement; however, the hanger will still be able to pitch correctly when traversing inclines and declines.

If you have H-attachment pendants on your line and are using round wire for the top of your hangers, and it is prohibitive to weld everyone with stabilizers, you may be able to add a welded saddle assembly comprised of two washers and a bushing with inner dimensions in close approximation to the hanger top material width or two convex washers (flat steel washers that have been press-broke to convex geometry) butted together at their apex (see Figure 2). Either will, in effect, create a “seat” for the top of the hanger to sit in and prevent twisting.

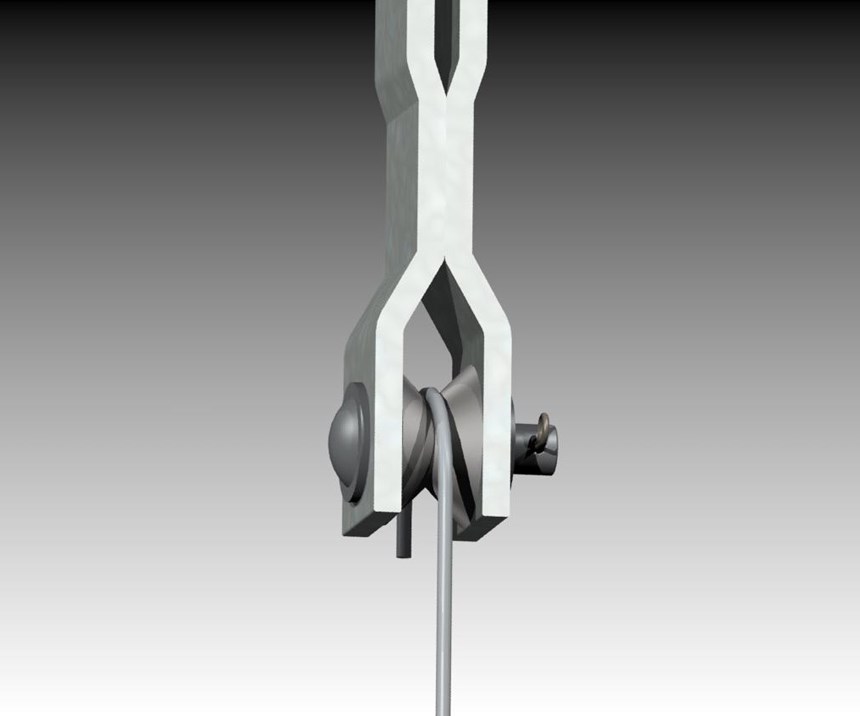

Customized stabilizing elements may also be integrated into the hanger design. For instance, plasma- or laser-cut hanger top profiles can be developed to effectively mate with a corresponding load bar design to eliminate lateral sway, but allow the rack to properly pitch on the inclines and declines of the conveyor (see Figure 3).

Optimal tracking accuracy can be obtained by a properly engineered load bar and hanger design where a close, accurate central rack mounting allows the rack to remain level during inclines and declines. For instance, a leading appliance manufacturer in the U.S. has deployed such a product on its porcelain cooktop processing line and as a result is achieving +/-¼" on the edges of 30” range tops, corresponding to +/-1 degree. Due to the fact that porcelain powder application is more demanding than organic powder coating (because of higher specific gravity and less charge-retention capability), this is a real game changer.

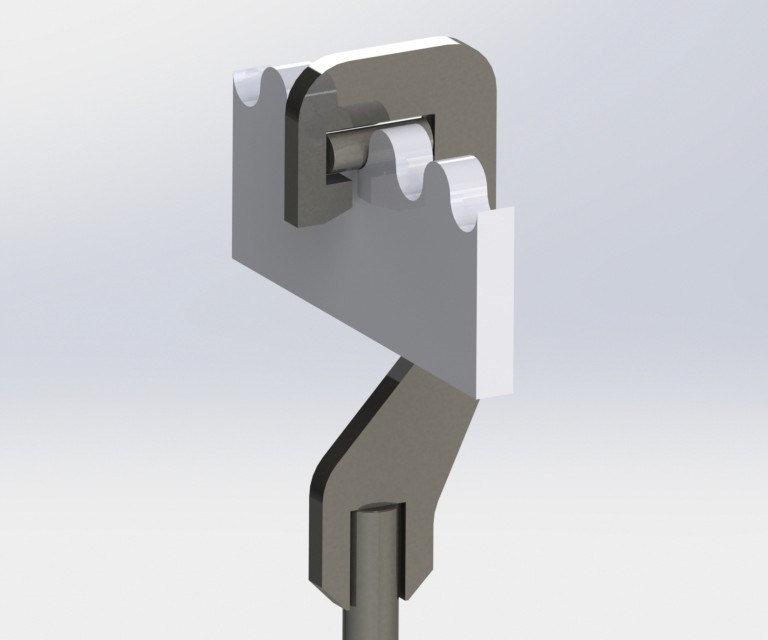

Sometimes the hanger-twisting issue does not originate from the hanger-to-conveyor attachment method, but somewhere further along the vertical plane where the hanger attaches to something else. This may include a drop hook (an intermediate hanger/hook implemented to set the part hanger in the proper spot of the rack window) or beneath a rotator, or where successive hangers are laddered or daisy-chained together. Those connections will also create pivot points and require stabilization. Creating a stable connection in these areas may be a bit tricky because they often lie within corona spray zones and will build up coating, which increases difficulty in removal. One good method is using a Donny joint (named after Donny Yates, an early pioneer in hanger technology), which uses a section of roll-formed, diamond-shape tubing and a ¾ square mating pin with offset tab. This clever little design reduces the exposed area of contact in the corona zone, but maintains internal metal-to-metal contact, providing consistent ground (see Figure 4).

Simply put, improving hanger tracking does not need to be complicated. Usually, an inexpensive, quick, small fix will eliminate the problem. The cost savings resulting from improved quality and reduced rework will significantly outweigh the expense of the modification. As the great painter Vincent Van Gogh once said, “Great things are done by of series of small things brought together.”

Scott Rempala is president of Mighty Hook. Visit mightyhook.com.

Related Content

Conveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreTop Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

Read MoreAnodizing for Bonding Applications in Aerospace

Anodizing for pre-prep bonding bridges the gap between metallic and composite worlds, as it provides a superior surface in many applications on aluminum components for bonding to these composites.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More