Is it possible to be both lean and green in the finishing world?

Lean manufacturing says that money spent on resources for any goal other than the creation of value is wasteful and should be eliminated. Green technology seeks to conserve natural resources and curb the negative impact of humans. Therefore, by improving efficiency in our coating processes, we can be both lean and green.

The Cost of the Coating Process

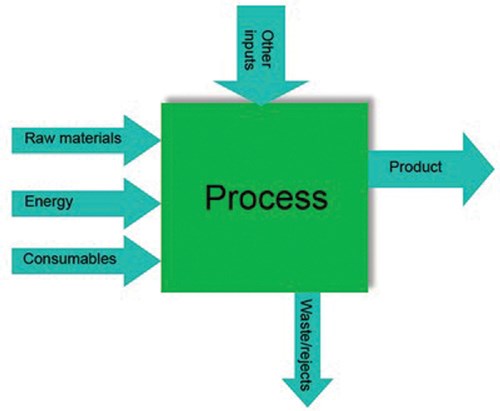

Coating materials is a process with four fundamental costs: labor, materials (chemicals and coatings, energy and reject or rework.

Let’s assume you hire smart, dedicated people. They labor long and hard, and they have your best interests at heart.

Your next big cost is material—your chemicals and coatings. Here’s a word of advice: befriend your chemical and coatings suppliers. Make them your best buddies. Why? Because your chemical supplier makes the washer work better, and your coatings supplier makes all the parts bright, shiny and corrosion resistant.

Your chemical supplier furnishes the cleaning solution, the phosphate solution, rust inhibitors and rinse agents you use in your multistage washer. A good chemical supplier will climb into the washer to aim the nozzles, set up a preventative maintenance schedule and frequently check on how you are doing.

A good coatings supplier will periodically run his temperature logger through the oven (at no charge to you) to assure the oven temperature and uniformity are sufficient to guarantee the coating’s performance. He also can help improve your transfer efficiency—the amount of paint that ends up on your product divided by the amount of paint that comes out of the gun.

Both suppliers have a vested interest in making sure your parts are clean and the paint will stick. They want you to succeed so you buy more of their products. They don’t want you to get too chummy with some other chemical or coatings suppliers, because they want to sell you chemicals and coatings for the next 20 years.

Your next big cost is energy. Here, your chemical and coatings suppliers can help you, too. Their companies invest millions in research and development and are constantly coming up with new and better products. Some of these new products often work at lower temperatures. Lower temperature means you can use less energy, and that can mean big cost savings.

Ultimately, getting the “right-sized” equipment for your needs is crucial. Adequate part-opening size (too larger means more heat loss, and too small means parts won’t fit) and conveyor design speed (too fast means the capital cost for your equipment is more than it has to be, and too slow means you won’t make your production rates) are important decisions. Bigger and longer is not necessarily better.

Energy Saving Design and Retrofits

There are a variety of energy-saving add-ons that should be considered when purchasing an industrial oven. Some may also be purchased as retrofits to your existing oven. These include:

Lower operating temperatures. If you can use a different chemical or a different coating that doesn’t require you to put as much heat into the process, you keep more money in your pocket.

Additional insulation. Spray washers are often uninsulated. Ovens usually have the minimum amount of insulation to meet OSHA requirements for hot surfaces. Insulation is cheap. Adding additional insulation keeps the heat where you want it (in the equipment) and away from were you don’t want it (in your plant).

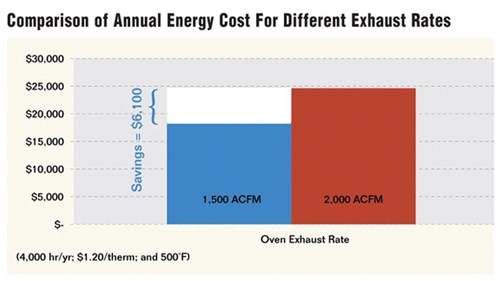

Minimized exhaust rates. A certain minimum is required by code, but why heat the outdoors? (Maybe there is something to that whole global warming thing.)

Premium efficiency motors. Current regulations require all new motors to meet the Energy Independence and Security Act of 2007 (EISA). If you are using old motors, replace them. A high-efficiency motor is the gift that keeps on giving.

Consider a variable frequency drive (VFD). Ovens have to start cold, but they operate hot. Your fan motor is sized for a cold start. When you reach operating temperature, the horsepower requirements drop off. If you use a VFD, you can size the motor for the operating point, not the cold start load. You can often drop one or more motor sizes when you use a VFD.

Energy Saving Examples

One finishing business switched to a new cleaning solution with a lower operating temperature that saved him 12 therms per hour. At his energy cost 95 cents per therm, that amounted to $11.40 per hour—a savings of almost $24,000 per year for a single eight-hour shift.

On another project, simply insulating the tank and housing led to significant savings. Just $5,000 for insulation resulted in a savings of nearly $2,000 per year (eight-hour shift), a payback in less than two and a half years.

Minimizing end openings (and therefore exhaust rate) can have an even shorter payback.

Infratrol Manufacturing Corp. saved another customer more than $15,000 per year (eight-hour shift) for $4,200 worth of automatic doors for the product openings.

Rejects and Rework

The last major cost of the coating process is the reject or rework you have to do. Reducing these often requires a combination of factors. Start with good people. Be sure they properly maintain the equipment, ovens are cleaned regularly, and filters are cleaned or changed. Run oven profiles on a regular basis to insure that your curing profile (time and temperature) is adequate. Under-cured or over-cured parts are often scrapped, or they have to be cleaned and re-coated.

Lastly, talk to your two best buddies—your chemical supplier and your coatings supplier—because they can help you get better results and reduce the waste associated with rejects and reworking of products.

After all, reducing waste (lean) and running more efficiently (green) are a big part of the goal.

Steven Onsager is president of Infratrol Manufacturing Corp. He can be reached at 262-797-8140.

.jpg;maxWidth=300;quality=90)