Managing Gold Plating for Electrical Contacts

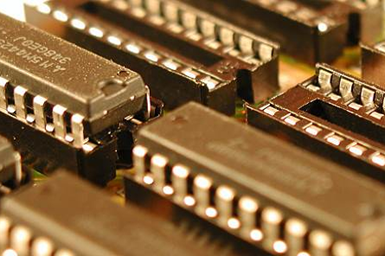

With electrical contacts continuing to grow smaller, platers need to know how to manage the three key considerations of gold plating: thickness, purity and underplate chemistry.

Q. What considerations should plating specialists keep in mind when working with gold plating for electrical contacts?

Gold has been and continues to be a principal finish for electrical components, especially with the ongoing miniaturization of electronics. One of the primary benefits of gold plating is a finish that is both conductive and receptive to soldering. When soldering gold-plated components, there are a variety of important considerations to remember, the most important of which are thickness, purity and underplate chemistry.

Plating Thickness

Gold-plating thickness is a critical and often misunderstood tenet of gold soldering. In gold soldering, the physical bond is between the underlying nickel layer and the solder itself, with the gold layer serving as a barrier to help maintain the solderability of the nickel layer. Typical gold thickness for solderability is in the range of 10–30 µin to provide adequate protection against oxidation and preserve wetting while keeping the cost of the finish as competitive as possible.

When soldering, gold dissolves into the solder through solid state diffusion. With heavier gold deposits, more gold alloys form within the solder joint. The gold reacts with the solder in the diffusion process to create a gold intermetallic amalgam. If the gold in the solder exceeds 3% by mass, the solder joint can become embrittled and cause joint failure, especially in dynamically or thermally stressed joints. The level of impurity and thickness of gold are directly related, thus thickness of the gold must be balanced between corrosion/oxidation protection, contact cycle life and solderability.

Purity

Purity of both the gold and underplate layers is critical in order to achieve optimal solderability. For gold plating, it is important to minimize organic impurities through proper tank maintenance. Organic impurities that are imparted into the plating layer can interfere with the soldering and cause dewetting or voids in the solder. Soft gold of 99.9% purity is typically the preferred gold for bonding or soldering applications. While nickel- or cobalt-hardened gold can solder well and provide improved wear resistance on contact surfaces, the purity of the hard gold requires preservation through proper analytical work and tank maintenance.

Nickel purity is also critical, as this layer is the functional bonding layer. For nickel soldering, higher purity nickel results in better soldering. Plating companies often use an organically brightened nickel layer such as a brightened Watts or sulfate-based nickel to give a bright finish at the expense of solderability.

Instead, use an engineered sulfamate nickel-plating layer as an underplate for gold plating, including for soldering applications. This nickel system is free of co-deposited organics that can outgas or volatilize during soldering, thereby causing voids in the solder joint.

Another common underplate for gold plating is electroless nickel. While there are many advantages to electroless nickel plating — tight tolerances, large deposit ranges, corrosion protection and lubricity — this material deposits phosphorus on the surface in conjunction with nickel. The phosphorous acts as an impurity and can impede soldering. When specifying electroless nickel deposits, a medium phosphorous electroless nickel can balance the positives of electroless nickel while preserving solderability.

Solder Process

When designing a solder process for gold-plated parts, it is important to remember that the solder joint forms between the solder and the nickel. Therefore, when performing multiple solder operations or reflow soldering, finishers should allot additional liquidous time to provide ample time for the solder to bond to the nickel. In addition, instead of using a typical rosin-only flux on very thin gold deposits that are significantly aged, a rosin mildly activated (RMA) flux can help with removing nickel oxides that may have propagated through the gold layer to the surface.

Microelectronics

Soldering to gold plating is becoming more and more prevalent with the rise in high-end microelectronics. It is more important than ever to understand the process of soldering to gold and designing surface finishes to provide the most robust, cost-effective finish possible. The ideal gold finish must balance corrosion and wear performance with solderability to ensure the best possible design.

Related Content

How to Choose Between Sulfate and Chloride-Based Trivalent Chromium

There are several factors to consider when choosing between sulfate and chloride-based baths for trivalent chromium plating. Mark Schario of Columbia Chemical discusses the differences and what platers should keep in mind when evaluating options.

Read MoreInnovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreSuccessful South African Plater Beating the Odds

Remaining focused on quality and reliability, Team Plating Works stays profitable in a volatile and challenging economy.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More