New Electrocoating Equals Success

An increase in quality. An increase in production. A corporate initiative to reduce waste. All of these were factors in Modine's adoption of a new electrocoating. While the transition wasn't easy, it certainly has paid off . . .

So, your customer wants to change the finish on its part. In the customer's mind, it might not be a big deal. But, for you and your shop, it can be a difficult and complicated process.

Even when you have the time to analyze the change from every conceivable angle, there always seems to be something you didn't consider. Will the pretreatment still work? Will the waste treatment process be affected? Will I need to change my manufacturing process? "New system installation of this size requires close cooperation between all parties involved, including manufacturing engineering, production, environmental engineering and all suppliers," stated Todd Seversen, process chemist—coatings for Modine.

Why Change?

Modine Manufacturing (Racine, WI) is a world leader in heat transfer solutions. Its Jefferson City, MO, plant manufactures large radiators that are used in engine cooling packages on construction and agricultural equipment. The plant's initial foray into electrocoating was brought about by one customer's need for increased corrosion protection. "We got into electrocoating because a customer wanted it. It was necessary to increase the corrosion protection of a high-fin-density radiator module that was susceptible to rusting due to its operating environment," stated Larry Armstrong, senior process specialist at the Jefferson City plant.

To electrocoat this part, Modine installed a part-specific electrocoating system, which was specially designed to handle the size and square footage of the new radiator module. Modine's original plan was to run this system two shifts per day. But, once the system was installed and production began, Modine was running three shifts per day, six days a week (sometimes seven days a week).

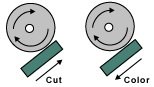

Because of its success electrocoating the high-fin-density radiator module, Modine decided to electrocoat its standard radiators as well. While other customers would have allowed the manufacturer to spray paint these parts, Modine was not satisfied with the quality of that system because of the inconsistent finish it produced.

However, this increase in production began to overload the system. According to Mr. Armstrong, "The problem was all the combinations kept growing. And, we had more production than we could electrocoat through that system. We had to start looking for another system. The drive wasn't actually so much for a different method as it was for a system with increased capacity and a more environmentally friendly electrocoating that could still provide comparative corrosion protection."

The Jefferson City plant's desire to find a more environmentally friendly coating dovetailed with Modine's corporate initiative to reduce the company's environmental impact. "We do have a corporate initiative at Modine of reducing and eliminating waste. This is part of a Modine environmental program that says ‘Here's a list of chemicals we're getting out of.' Some of the chemicals in the previous generation electrocoat as well as the spray painting process were on that list," explained Dave Peterson, supervisor corrosion and chemical engineering at Modine.

Because Modine was not forced to make the switch to a more environmentally friendly coating by environmental regulations, the company had the time to search for the right solution instead of making a hasty decision. "We were fortunate in a way that we didn't have to get out of it as soon as some other plants. That helped us," stated Mr. Armstrong. "We looked at things and said this isn't an improvement, it costs more, we don't have to do it yet. Let's keep looking. Some of our other plants in other locations didn't have that option."

A Difficult Transition

Even though the Jefferson City plant had the luxury of time in making its decision, once the decision was made, Modine's customers wanted the change to happen fairly quickly. This made the transition to electrocoating a difficult one. The company faced a number of issues, including plugging, curing and hanging the radiators, that affected the quality of the finish produced by the electrocoating system.

"Some of them were self-induced by trying to put everything on there too soon," explained Mr. Armstrong. "There was just not enough time to get all of the things that needed to be done in the way of plugging the radiators and the hanging issues. We just had enough trouble that electrocoating kind of got a black eye. And, we went back to spray painting."

But, the move back to spray painting was only a temporary one thanks to Modine's electrocoating supplier, PPG Industries. "They held up their end of supporting us through that first machine exceptionally well and have never faltered since. They've been there any time we needed any kind of support," explained Mr. Armstrong.

New Electrocoating = Success

Modine's move back to spray painting was only a temporary one because PPG engineered an electrocoating to meet Modine's needs. The most important change in the formulation of the new cathodic epoxy electrocoating for Modine was the reduced cure temperature. This has eliminated all of the curing problems that Modine was having with its sheet metal radiators. In addition to its low cure temperature, the new electrocoating is lead and HAPs free and has a low solvent content.

The new formulation has provided Modine with a number of benefits, including better edge coverage, increased corrosion protection, elimination of hazardous waste sludge and HAPs and better efficiency. Better edge coverage is a tremendous benefit for Modine, especially on the high-fin-density radiator modules. Because the fins are so close together on this part, there are a number of recessed areas and many leading edges. With the previous electrocoating system, Modine was not getting enough coating on the recessed areas and too much on the leading edges. In fact, the electrocoating had a tendency to bridge over the fins, obstructing airflow through the radiator. But, the new electrocoating has the throw power to get into the recessed areas without bridging the radiator fins, according to Brad Piening, manufacturing engineer at the Jefferson City plant. The better edge coverage coupled with Modine's application system has greatly improved the corrosion resistance of the coating on the radiators.

Another significant benefit for Modine was the elimination of hazardous waste sludge. This is possible because the electrocoating is free of heavy metals. "This is an issue that's often overlooked when looking at the conversion from spray to electrocoat. You simply do not have any waste issues. You don't have to distill the waste down and ship it out as hazardous waste. We have eliminated all our sludge barrels going out the door by eliminating spray painting. And, it certainly made for a more operator friendly system," stated Mr. Piening.

The switch to electrocoating has also made Modine's coating process more efficient. "As far as transfer efficiency is concerned, we're much more efficient. Basically, it's 100%. You only lose whatever small, minute percentage you drag out," said Mr. Piening.

While the transition was not smooth, the benefits of the new electrocoating made it worthwhile. Plus, the transition reinforced the notion that a close relationship between finisher and supplier is needed to ensure a high-quality product.

Related Content

Conveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreECOAT24 Issues Call for Speakers

Don't miss your chance to apply to speak at ECOAT24. Submit your abstract by June 26, 2023.

Read MoreProfessional Plating Expands Zinc, Ecoat Offerings

Ever expanding, Professional Plating of Brillion, Wisc., has announced two capital investments: a second zinc line and an upgrade of its ecoat capabilities.

Read MoreFinishing Systems Provider Celebrates 150 Years, Looks to Future

From humble beginnings as an Indiana-based tin shop, Koch Finishing Systems has evolved into one of the most trusted finishing equipment providers in the industry.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)