In the product finishing world, there are four common precision cleaning processes: hydrocarbon, aqueous, semi-aqueous, and vapor degreasing. Each choice has its strengths and its disadvantages, but one of the biggest problems with aqueous and semi-aqueous cleaning is the quantity of the electricity it takes to operate those systems.

Let’s face it: all energy costs are rising and electricity is no exception. On a historical basis, electricity already is expensive and getting more so. Capacity is another issue: the recent cold winter in Texas generated an energy crisis there and “rolling black outs” were inflicted on companies due to lack of sufficient generating capacity at the time. Additionally, the production of electricity by burning hydrocarbon fuels is a key contributor to global warming.

Vapor degreasing can dramatically reduce a company’s energy budget devoted to cleaning processes.

SOLVENT CHEMISTRIES

It has only been in the past decade or so that leading companies have commercialized new, environmentally-acceptable cleaning solvents suitable for vapor degreasing. This means that the speed, convenience and energy savings of this proven technology now is available to engineers everywhere.

Unlike aqueous or hydrocarbon cleaning, vapor degreasing requires special fluids with a unique combination of characteristics. Ideally, these cleaners should be nonflammable, immiscible with water, have a low boiling point, an appropriate Kari-Butanol (Kb) value, a high density, low surface tension, low viscosity, a low specific heat and a low latent heat of vaporization. Developing fluids with all of these characteristics has not been easy for DuPont, 3M, and the other suppliers.

Four of these characteristics affect cleaning performance. The high density, the low surface tension and low viscosity all ensure the solvent will wet every surface, getting into (and out of) tiny nooks and apertures. As the old adage goes, if you can’t wet you can’t clean.

The Kb value measures the strength of the fluid, and ensures the solvent will have the “muscle” to deliver dissolve any contamination. So far, so good.

But it is the low specific heat and a low latent heat of vaporization that are the primary reasons a vapor degreaser is significantly more energy-efficient than other technologies.

The energy inefficiency of water cleaning stems right from the chemical properties of water itself. The inherent characteristics of water make it very difficult to use and to remove water efficiently from complex surfaces. By comparison, solvent cleaning is highly energy-efficient.

The term “specific heat” defines the amount of heat required to raise the temperature of a unit mass by one degree Celsius. The specific heat of water is very high, which is why oceans have such a very important role stabilizing global temperatures: it takes a lot of energy to heat or cool water. As an example, the specific heat for water is 4.186 joule/gram °C, which is four times higher than modern solvents such as nPB or the popular DuPont HFC cleaning chemistries.

After cleaning, most cleaning systems evaporate the cleaning fluid from the surface of the parts. Once a liquid begins to change phase – that is, change from a liquid into vapor –specific heat is no longer used. The proper statistic to measure the energy required to evaporate a fluid is “the latent heat of vaporization.” And therein lies the rub: it takes a great deal of energy to evaporate water.

Specifically, water requires 970.4 BTU of energy to vaporize one pound of liquid. In contrast, nPB requires only 58.8 BTU for an equal weight, and the popular DuPont HFC solvents require only 67.1 BTU/pound. This means it will take roughly 14 times more electricity to evaporate a pound of water than to vaporize a pound of solvent.

AQUEOUS CLEANING ENERGY CONSUMPTION

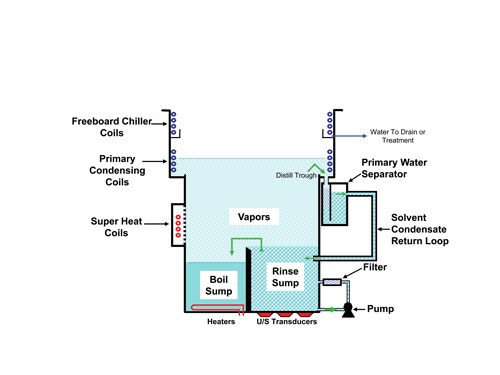

Most aqueous cleaners are horizontal designs which use hoists or conveyors to move the parts through a series of dip tanks. A typical aqueous batch system has one wash tank and between two to five reverse-flow, cascading rinse tanks that require 2-5 gallons/minute of deionized water. These systems typically will be 50-150% larger than vapor degreasers of the same capacity, simply because of the need for more tanks, larger pumps, blowers, filters and so on. Typically these machines use about 8-10 kW of electricity per hour of operation. Most aqueous cleaning systems have three or more tanks with ultrasonics, adding another 1-2 kW of energy consumption.

Aqueous system cleaning cycles tend to run longer than vapor degreasers. Cleaning cycles of 20-40 minutes are not uncommon. Most vapor degreasers clean in 5-12 minute cycles, reducing energy costs and work in process inventory.

Removing excess water from parts is challenging because of the chemical nature of water discussed above. Evaporating the excess water with heat is relatively slow and expensive, so the most common drying option is an “air knife.” A typical aqueous system easily can use 5 kWh at the drying stations, and that number could double on a bigger machine simply because of the increasing size of the motors, fans and compressors. Ultimately, for final drying, heated air knives often are necessary – which simply compounds the energy consumption problem.

Water pre-treatment and post-treatment systems also use large quantities of electricity. Once the water is deionized, the water is usually heated to 140 - 160°F for the cleaning process which requires at least 2-3kW of power or more for the pumps and support equipment. On the back-end, assuming the system needs to process five gallons of waste water a minute, even the most frugal waste water system is going to need 3-5 kW of power.

One last consideration is the stand-by power draw. At many companies the aqueous cleaners never are shut down because of the cost and the delay in re-heating. These systems will use 2-5 kW of electricity at a minimum, hour after hour, even when no cleaning operations are being conducted.

Here’s a detailed example: A Branson 1620 aqueous system with modest cleaning capacity costs around $85,000. It has four sumps and is almost 15 feet long, twice as large as an equivalent vapor degreaser. It uses 17kW during start-up and 12kW during use, plus whatever ultrasonics, operating at 140°F. The total system will use approximately 25 kilowatts per hour.

Aqueous cleaning machines also add heat to the surrounding environment which increases the load on the air conditioning system. The Branson 1620 will add nearly 300,000 BTU/hour of heat to the room in which it is operating plus approximately 15 pounds of water (roughly two gallons) into the air of the plant every hour, which will need to be removed by the HVAC system. Vapor degreasers, with the new low-temperature solvents, make only a minimal contribution in this manner.

DOING THE NUMBERS

It’s clear that the fundamental chemical characteristics of water make it inevitable that aqueous cleaning will consume far more kilowatts to clean as the systems need to purify the water, clean the parts, dry the parts and then re-treat the water after cleaning. In contrast, some small vapor degreasers operate on 120v power supplies.

A general rule-of-thumb is that any aqueous cleaning system will use ten times the energy of a vapor degreaser of comparable capacity. Another estimate calculated using the specs from two cleaning machines suggests that a small facility will save a minimum of $300/month in direct energy costs by switching to vapor degreasing.

As substantial as those numbers are, many companies find the cost savings to be even greater. One company in the Midwest was a long-term aqueous user. It was able to document massive savings by switching to vapor cleaning. The local electrical utility provided a grant that funded 100% of the purchase of the new cleaning hardware.

But that’s just the beginning. Other savings, from faster throughput to higher yields and fewer defects all contribute to ever greater profitability.

With energy costs rising and the availability of adequate water supplies becoming a global concern, it makes sense to give energy-efficient solvent cleaning another look. n

Mike Jones is the Vice President of MicroCare Corp., a U.S.-based specialty firm dealing with precision cleaning, coating and lubrication. He thanks John Hoffman for his assistance preparing this article.