PPG Highlights New Corrosion-Resistant E-Coats At NAIAS

Pproducts are designed to fight metal corrosion and meet increasingly stringent environmental standards.

PPG Industries’ industrial coatings business highlighted new products during preview days at the 2015 North American International Auto Show (NAIAS) in Detroit’s Cobo Center, Jan. 12-15.

The products are designed to help global automakers fight metal corrosion and meet increasingly stringent environmental standards around the world. They include:

· POWERCRON ADVANTEDGE and POWERCRON EPIC Tin-Free Electrocoats – Powercron AdvantEdge and Powercron EPIC e-coat systems are formulated with a proprietary catalyst that functions without tin, bismuth or other heavy-metal compounds, representing a significant environmental advance by PPG in corrosion-fighting products for the auto industry. In addition to helping auto manufacturers comply with new global environmental regulations, the technology enables PPG’s ninth-generation e-coats to cure at temperatures as low as 320 F to reduce energy consumption and related carbon emissions.

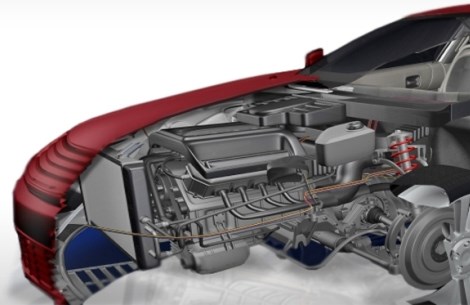

· PPG Proprietary Zinc-Rich Primer with Electrocoat – PPG’s latest technology breakthrough is a duplex coating system that incorporates an “engineered” zinc-rich primer between the metal substrate and e-coat finish. Together, the primer and e-coat significantly improve the corrosion resistance of high-end underbody parts, subframe finishes and other vulnerable parts on trucks and passenger vehicles.

· Metal Conditioner 257 (AMC257) for Mixed Metal Pretreatment Systems – A near-neutral pH pickle/descaler, Metal Conditioner 257 removes weld scale and light oxides from steel surfaces. The product is ideal for use in mixed-metal pretreatment systems because it preconditions welds and heat-affected zones prior to phosphating without significantly affecting white metals, galvanized steel and aluminum surfaces, enabling them to be processed at the same time as steel. As a mildly acidic pickle/descaler, AMC257 is more sustainable than conventional mineral-acid pickle solutions because it is non-fuming and operationally easier and safer to use.

· VERSABOND Pretreatment System – In response to the increased use of aluminum in trucks and passenger vehicles, PPG has developed the Versabond pretreatment system, which employs the latest in zinc-phosphate hypernucleation technology to accelerate crystal formation and thereby reduce the production of sludge by up to 50 percent in some pretreatment systems. Other environmental and performance benefits associated with the Versabond pretreatment system include 10 to 20 percent lower processing temperatures and excellent corrosion resistance and adhesion due to its ability to uniformly deposit small, densely packed zinc-phosphate crystals.

For more information on the products featured or PPG’s hospitality suite at NAIAS, visit ppgindustrialcoatings.com or call 1-888-774-2001.

Related Content

-

Sustainability, Electrification and Mobility

Industry events like ECOAT are good indicators of the trends that are top of mind for those in manufacturing.

-

Professional Plating Expands Zinc, Ecoat Offerings

Ever expanding, Professional Plating of Brillion, Wisc., has announced two capital investments: a second zinc line and an upgrade of its ecoat capabilities.

-

Coatings Plant Evolves with Market Trends

Expanding its focus from exclusively serving the RV industry, one of this company’s stand-alone coatings plant has successfully extended its services to additional markets.