Praxair Surface Technologies and GE Aviation Form Joint Venture

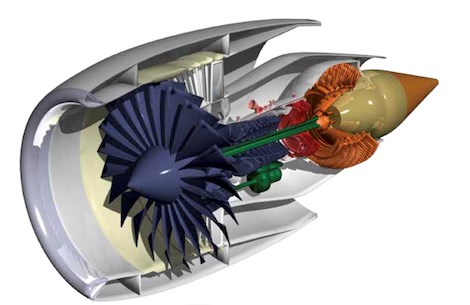

The coatings will be tailored for GE Aviation’s and CFM International’s current and future engine models, including the GE9X and LEAP engines

Praxair Surface Technologies and GE Aviation have entered into a definitive agreement to form a joint venture for the development, support and application of specialized coatings.

The coatings will be tailored for GE Aviation’s and CFM International’s current and future engine models, including the GE9X and LEAP engines.

When created, the joint-venture company will expand its footprint with a new coatings plant in the southeast United States, which will supplement the services provided to GE from Praxair’s Indianapolis facility and other global operations. Additionally, under the agreement, Praxair Surface Technologies’ current scope of services provided to GE Aviation will be expanded. GE Aviation production volume will continue to grow due to a large backlog of commercial engine orders.

Praxair Surface Technologies will be the majority owner of the venture and will consolidate the results. GE Aviation will hold the remaining membership interests. The parties plan to begin operations during the second quarter of 2016, once regulatory approvals are obtained.

“We are delighted to expand and formalize our long-standing relationship with GE Aviation and combine efforts to provide exceptional service, capabilities and technologies to the growing aviation industry,” said Praxair Surface Technologies President Pierre Lüthi. “Together, we’ll enhance our advanced coating capabilities to provide a dedicated coating source and support the growth of GE’s new engine platforms.”

“This specialized coating joint venture with Praxair will enable us to meet our growing engine production volume,” said Colleen Athans, vice president and general manager of GE Aviation’s Supply Chain. “The unique coating capabilities will enhance our engines’ performance and durability, which are key requirements for our customers.”

Related Content

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

-

An Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

-

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.