Proper Paint Storage and Use

Geoff Raifsnider, senior engineer, Global Finishing Solutions, discusses what you need to know about proper paint storage for your finishing operation.

Most paints used in finishing operations are classified as either a flammable or combustible liquid. Under certain conditions, these liquids can produce vapors that may ignite, causing a fire or deflagration.

That is why codes and standards outlining proper storage guidelines have been developed to minimize risks and protect your workers, equipment and facility. Understanding these codes and standards is key when storing, dispensing or mixing paint and selecting the right type of enclosure for your needs.

Adding a paint mix room or hazardous material storage building enables you to dispense or mix paint in a clean, ventilated environment, reducing the chance of contamination in your paint job.

It is important to understand the characteristics of the paints used in your operation; safety data sheets (SDS) provide key information. You also should know the answers to the following commonly asked questions before investing in an enclosure for paint storage or to contain a mixing, dispensing or pumping process:

1. How much paint can I store or have in use in my facility?

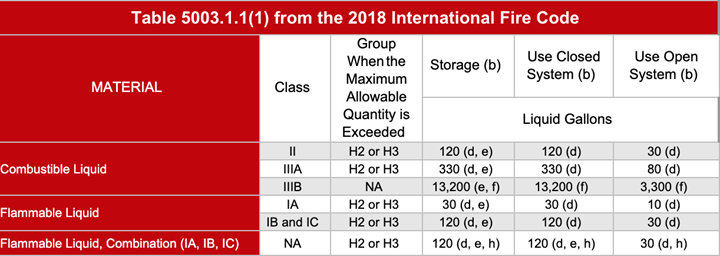

The amount of paint you can store or have in use in your facility is dependent on which class of liquid your paint falls within and the Maximum Allowable Quantity (MAQ) — the limit on the amount of flammable or combustible liquid present before additional measures are required to mitigate the hazard. The MAQ not only varies based upon the class of the liquid, but also whether the container is open or closed. The MAQ values can be found in NFPA 30, NFPA 33 and the International Fire Code (IFC). The table below is a summary of the information contained in the IFC:

Image Credit: 2018 International Fire Code

If your building is equipped with an automatic sprinkler system, the MAQ for storage and use can be increased by 100%. The amount in storage can be increased by another 100% (for a total increase of 200%) if stored in an exhausted enclosure, such as a mix room or hazardous material storage building.

2. When do I need a mix room or hazardous material storage building?

When transferring paint between containers or mixing liquids into one container, code requires you to perform these operations in a mix room or in a spray booth with the ventilation on. Since mixing paint in a spray booth dramatically slows down your finishing operation, having a dedicated space such as a mix room is ideal.

If the amount of paint stored in your facility is over the MAQ, including the increases for ventilated enclosures and fire protection systems, a hazardous material storage building is your best option. With a fire-rated ceiling and walls, a hazardous material storage building creates a separate control area — an area protected from fire — from the rest of your facility.

NFPA 33 limits how much liquid can be in a mix room, depending on its proximity to a spray booth. If a mix room is located adjacent to or within 6 feet of a spray booth, the combined amount of liquid in the mix room and the spray booth cannot exceed 120 gallons or 2 gallons per square foot of the mix room (whichever is less); the maximum amount of liquid permitted in a spray booth is 60 gallons. For mix rooms located more than 6 feet from a spray booth, the amount of paint in the mix room cannot exceed 2 gallons per square foot, regardless of the class of the liquid.

3. How many mix rooms or hazardous material storage buildings can I have in my facility?

There is no limit on the number of mix rooms or hazardous material storage buildings allowed in one facility. However, a mix room cannot exceed 150 square feet, and no more than 300 gallons of flammable or combustible liquids may be stored among all your mix rooms combined, as they do not qualify as control areas since they are not constructed to have a fire rating.

4. What are the ventilation requirements for mix rooms and hazardous material storage buildings?

When vapors are present, the minimum ventilation required for a mix room is 150 cubic feet per minute (CFM). Recent changes to NFPA 33 state that ventilation is required only when you have open Class I, Class II or Class III liquids at temperatures at or above their flashpoints. Class IA and IB liquids have a flashpoint below 73°F, meaning ventilation is still required, as interior temperatures will likely exceed the flashpoint.

For hazardous material storage buildings, mechanical ventilation systems are required only for locations where Class I liquids are dispensed, according to NFPA 30. However, the IFC requires ventilation where paint quantities have exceeded the MAQ. For both codes, the ventilation rate is 1 CFM per square foot of floor area but not less than 150 CFM.

5. What are the electrical area classifications of mix rooms and hazardous material storage buildings?

The electrical area classification of a mix room used to be Class I, Division 1 throughout — the same as a paint booth. The revised standard allows you to apply the guidelines in NFPA 30 to establish potentially different area classifications. While there may be some cost advantages to this approach, any changes require a re-evaluation of the area classification and may result in modifications to the wiring or the location of electrical equipment.

The location of vapor sources is the determining factor for the electrical area classification of hazardous material storage buildings. Larger hazardous material storage buildings often have more space between vapor sources. As with mix rooms, NFPA 30 guidelines can be applied to establish the area classifications in a hazardous material storage building.

6. Does my facility need an explosion control method for a hazardous material storage building?

The IFC requires an explosion control method if you have exceeded the MAQ for storage or use of Class IA liquids or the MAQ for open use or dispensing of Class IB liquids. Explosion control is not required for Class IC liquids, Class II liquids or Class III liquids, nor for closed-use systems involving Class IB liquids.

When explosion control is required, deflagration (explosion) venting is the most common option. If the hazardous material storage building is indoors, it must be placed along an exterior wall, where the deflagration vent panels line up with penetrations in the building wall to allow for exterior venting.

Another option to achieve explosion control is deflagration prevention through concentration reduction. A hazard analysis must be performed to determine if any additional airflow is needed to reduce the concentration of flammable vapors present during a spill or other accidental release of the materials. Frequent maintenance and calibration of the equipment are also required to ensure the system continues to provide the necessary level of protection.

About the Author

Geoff Raifsnider

Geoff Raifsnider is a senior engineer for Global Finishing Solutions. Visit globalfinishing.com.

Related Content

Intumescent Coating Provides Up to 3 Hours of Fire Protection

PPG Steelguard 951 coating is designed to provide protection against fire and corrosion.

Read MoreConveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreCobot Enters Paint Industry With Safety at the Forefront

This collaborative robot is the first explosion-proof solution for the powder coating and paint arena that meets the U.S.’ stringent safety requirements. Its lead-through teach programming and tablet control are especially appealing to small shops with little proficiency in robotics.

Read MoreMasking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More

.jpg;maxWidth=300;quality=90)