Removing Contaminants Using CO2 Snow

Ever-increasing demands for clean component surfaces call for increasingly effective cleaning methods, like dry technologies.

Functional surfaces are an indispensable adjunct to innovations in mechanical engineering—and sometimes they are the actual drivers of change, says Dr. Thomas Schräder, managing director of the Air-Handling Technology sector of the German Engineering Federation (VDMA).

“Our sector is currently doing very well,” he said at the opening press conference for Surface Technology Germany, held June 5-7, in Stuttgart. “Only a short while ago, our association revised its growth forecast for 2018 upwards to 5 percent. However, especially at times of very rapid growth, it is important not to lose sight of the important issues that are in the process of shaping the future. Industry 4.0 is an absolute commercial necessity, not just a nice-to-have (perk).”

Parts cleaning and pretreatment was one of many topics covered at that show, and one presentation held at the Surface Technology Forum raised my interest: carbon dioxide (CO2) snow cleaning technology. Dry cleaning technology such as CO2 snow jet, plasma and laser beam cleaning increasingly find their way into the parts cleaning industry, as they allow for cleaning functional surfaces selectively—for example, before welding or assembly—offering savings potential, especially when combined with automation solutions.

Hans-Jörg Wössner from ACP GmbH in Ditzingen, Germany, discussed his company’s dry-cleaning technology using a jet of CO2 snow. The inline process can remove particulate and filmy contamination (dust, ablation residues, flitter, flux residues, smoke residues from laser processes, oils, fingerprints, cutting emulsions, polishing paste, and so on) from almost any material in a gentle, but effective manner, he said. “The process can be used not only to clean large surface areas, but also to selectively remove contamination from tiny defined functional areas with the highest cleanliness requirements.”

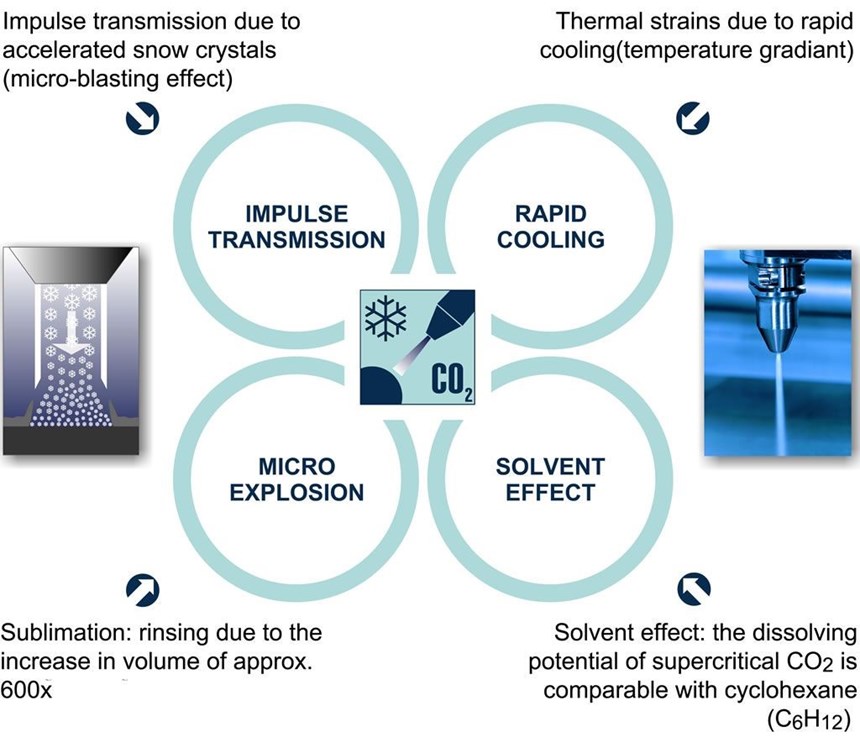

ACP’s snow cleaning system relies on the expansion of liquid carbon dioxide. The output stream is usually a high-velocity solid and gas mix, and focused at the surface for cleaning. The CO2 only transforms from a liquid to a solid state in the form of fine snow crystals as it leaves the nozzle. The crystals are then bundled by a circular jacketed jet of compressed air and advanced to the process zone at supersonic speed. Cleaning is accomplished by a combination of momentum transfer and solvent action of the dry ice with surface contamination.

The residue-free and nondestructive cleaning method removes particles in sizes ranging from visible to 3 to 5 nanometers; organic contamination removal matches that of commercial solvents such as cyclohexane (C6H12).

Related Content

-

3-Stage Versus 5-Stage Washers

Columnist Rodger Talbert explains the difference between a five-stage washer and a three-stage washer, and how one provides better corrosion protection over the other.

-

From Drain to Gain with Smart Wastewater Recovery

Incorporating digital monitoring to maximize performance.

-

Clean Technology Lasers for Coating Adhesion

Laser cleaning systems remove corrosion, grease, residue and existing coatings from metal surfaces quickly, with less preparation and mess than traditional techniques.