Rolling Along: Powder Coating Car And Truck Wheels.

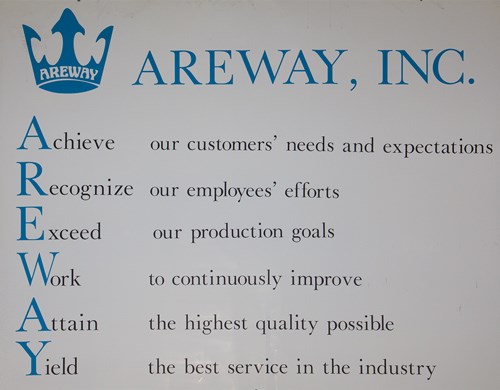

Areway Acquisition finishes forged and cast aluminum wheels for many of the cars and trucks that you see on the road today.

From Ford F150 pickup trucks and the new Chevy Camaro Z28 to Chrysler, GM and Ferrari vehicles, Areway Acquisition finishes forged and cast aluminum wheels for many of the cars and trucks that you see on the road today.

The single-source supplier offers complete in-house machining, automated polishing and buffing, powder and liquid painting, and an ISO-certified quality control system capable of ASTM, SAE and OEM specification testing.

The company was founded in 1967 by Sidor Hadgis as a family-operated polishing and buffing shop in the Cleveland suburb of Brooklyn, Ohio. Hadgis’ son, John, is the current owner of the business and oversees its daily operations.

In its early days, Areway polished, buffed and plated metal parts for a variety of industries that included automotive, truck and motorcycle as well as manufacturers of everyday home items such as pots, pans, appliance trim, and light and bathroom fixtures. Throughout the years, the company added both capability and capacity while maintaining high quality standards and environmentally friendly processes and products.

Areway says it was its commitment to quality that eventually led it to polishing and buffing forged aluminum wheels for Alcoa, which turned out to be a growing market for Areway, as more vehicles around the world are being fitted with forged aluminum wheels.

Forged Wheels

Depending on a particular wheel’s finishing requirements, the process steps can differ slightly. According to Areway, its high-capacity, proprietary buffing and polishing center can handle wheels as large as 30 inches in diameter, and a typical aluminum wheel finishing process starts with automated buffing and polishing. The wheel is sent through a custom-designed 13-zone pretreatment line that uses environmentally friendly cleaning solutions supplied by Henkel Corporation

The company says this pretreatment is an important step in the process, as it promotes coating adhesion and protects against corrosion. After pretreatment, the wheel then enters an oven for dry-off before powder coating.

Some wheels immediately receive a powder topcoat and then cure, while other wheels with different finishes require more process steps. Many are first coated with either an acrylic or a polyester powder primer supplied by AkzoNobel Powder Coatings. The color coat, if required, is often a waterborne liquid paint.

Two-Tone Colors

More complex finishes sometimes require machining in Areway’s new automated machining center. This process further enhances what becomes a two-tone color and silver finish, which the company says is currently very popular. Or, the wheel can receive either a high-gloss, clear acrylic powder topcoat or a matte polyester powder coating.

Areway says its powder and liquid paint finishing processes are extremely flexible to meet a customer’s specific desired finish.

Most powder coating at the facility is done in a single Nordson Corporation, Industrial Coating Systems Horizon 400 downdraft booth with one oscillator equipped with six oscillating Versa Spray II IPS (integral power supply) guns and a single Versa Spray manual gun. The manual gun is capable of coating from either side of the booth, depending on the finish requirements of the wheel. According to Areway, the Horizon 400 is, by far, the workhorse of the coating operation and is dedicated to the application of the acrylic clear powder for both primer and topcoat layers.

The IPS guns are controlled by an iControl integrated control system with closed-loop digital flow control. This measures fluctuations in incoming airflow and compensates with a proportional valve to ensure uniform flow to the pump, resulting in optimum repeatability and uniformity of powder on the part.

250 Presets

The iControl system is also capable of handling as many as 250 presets, which are pre-programmed recipes that control all application requirements for flow rate, atomizing, kV, AFC (current control) and triggering. Presets also can be customized for each wheel and powder. A typical wheel primer coat ranges from 1.5 to 2.0 mils, while a typical topcoat ranges from 2.0 to 3.5 mils. The presets can be named using a pop-up keyboard on the 12-inch, icon-based color touchscreen, making it easy for operators to select and switch between presets.

Adding Powder

Until 1995, Areway had little experience with powder coating. Choosing Nordson as its powder system and equipment supplier was an easy decision for the company, says Jeffrey Rabant, project manager for Areway’s finishing operations.

“Nordson was chosen because of its reputation as both a local supplier and worldwide leader of reliable and technologically advanced powder coating systems,” he says. “We’ve been extremely happy with Nordson’s powder coating system and the reliable and repeatable performance that it delivers on a daily basis.”

Areway says its demanding production schedule is testimony to Nordson’s reputation as a worldwide leader in the powder coating industry. The company’s highest annual production rate for coated wheels alone was 1.7 million. Currently, it runs two shifts for the machining, buffing and polishing operations, and one shift for the coating and finishing operations.

Bigger Wheels

Before the trend toward larger wheel diameters, Areway was utilizing 825 overhead conveyor hooks capable of producing 700 wheels per hour. Now with bigger wheels and a multitude of wheel designs, the company has had to increase the spacing between hooks and is utilizing 617 hooks capable of 480 wheels per hour if double hung, and 240 wheels per hour for even larger diameter single-hung wheels.

A typical customer order size can consist of 25 to 2,000 wheels to be delivered the same week. In addition to the Nordson Horizon 400 system, Areway has since added a Nordson COE (chain-on-edge) booth to spray tinted acrylic powder coatings, grey primers and polyester powder matte finishes onto the wheels. According to the company, the purchase of this second system illustrates Areway’s wheel finishing flexibility and its commitment to continuously expanding its capabilities to better service its customers.

So, next time you’re out driving and you see a sleek new Camaro Z28 in all of its muscle-car glory, or any other vehicle with aluminum wheels rolling down the road—anywhere around the world—it is quite possible that it was finished at Areway Acquisition in Brooklyn, Ohio.

For information on the following suppliers, please visit their websites: Nordson at nordson.com; Henkel at henkelna.com; and Akzo Nobel at interpon.us.

Related Content

Titrations: To Automate or Not to Automate?

What considerations should you keep in mind for automatic titrations? Conor McAnespie of Hanna Instruments discusses the benefits of auto titrators.

Read MorePrecise Paint Flow Reduces Material and Labor Costs

Finding a more accurate paint proportioner for its application enabled this auto parts manufacturer to save significant costs and labor while increasing capacity.

Read MoreHenry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More