Shipshape Testing: Software Meets IMO PSPC Requirements.

\New regulations apply to seawater ballast tanks of all types of ships of not less than 500 gross tonnage, and double-side skin spaces arranged in bulk carriers of 150 meters in length and upwards

- Coatings Library: Creation and maintenance of the approved coatings supplier, together with product data sheets, material safety data sheets and other documents.

- Ship Structure: Using architects’ drawings or block diagrams, each area under consideration can be identified. Once set up, users can use the diagram to visually see the status of each inspection.

- Coating System: Each approved coating system can be created from the coatings within the library. Systems can be re-issued if a specification is changed.

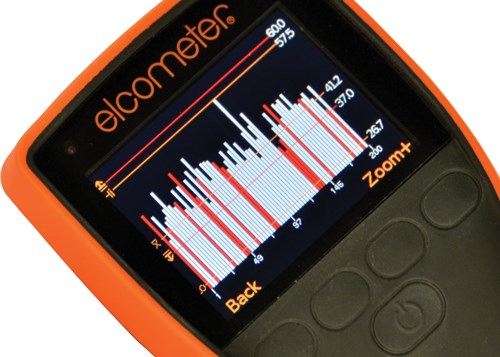

- Inspection Records: Visual, manual and digital inspection records can be recorded automatically using PDAs running ElcoShip Mobile or manually. Records by task, date, area under consideration and inspector, together with any requirement for rework or concessions, are all recorded. All inspections include a digital signature.

- Register of Inspectors: Details of all inspectors, together with their certifications, signatures, access rights to ElcoShip and other personnel documentation can be stored here.

- Daily Log: Summary of activities undertaken in the day are automatically reported in the Daily Log for the qualified inspector to review, add comments and approve.

- Inspection Regimes: Individual inspection points that can be grouped together as required.

- Change Log: Automatically generates a record of all activity undertaken, providing a full and instant audit trail.

Related Content

Cobot Enters Paint Industry With Safety at the Forefront

This collaborative robot is the first explosion-proof solution for the powder coating and paint arena that meets the U.S.’ stringent safety requirements. Its lead-through teach programming and tablet control are especially appealing to small shops with little proficiency in robotics.

Read MoreConveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreCoatings Plant Evolves with Market Trends

Expanding its focus from exclusively serving the RV industry, one of this company’s stand-alone coatings plant has successfully extended its services to additional markets.

Read MoreRobots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

Read MoreRead Next

Alodine EC2: ‘All aboard’ for saltwater corrosion resistance

Volvo Penta, a leading worldwide supplier of engines and complete power systems for marine and industrial use based in Chesapeake, Va., recently redesigned one of their leading engine exhaust systems and stern drives used on 20 to 35-foot pleasure craft.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More