Corrosion control is a goal of both machine and finishing shops. Metals are mined, refined and made into items useful in unstable environments. However, most metals eventually will revert to a more stable form, making them less than useful.

Over the centuries, materials have been developed and methods implemented to slow the corrosion process, including the use of oils to coat metal surfaces. From a cost and environmental standpoint, this is not necessarily the best way. Getting a better understanding of what causes corrosion and rust will help us develop new plans and materials to protect against this destructive metal state.

Causes of Corrosion

Nonferrous (non-iron) metals corrode primarily because of reactions with corrosive gases, also called “atmospheric pollution.” Even ferrous metals are severely impacted by these same corrosive gases, which act as corrosion accelerants. Metals corrode faster near the sea because there are higher levels of chlorides in the air, which are particularly damaging to stainless steel and aluminum. In fact, if we look at materials in general, the same corrosive gases that corrode and rust metals impact materials across the board.

Materials and How They Are Damaged

| Metal | rust/corrosion, discoloration, staining and weakening caused by corrosive gases |

|

Plastic |

strength loss and discoloration caused by ozone, ultraviolet rays and nitrogen oxides |

| Rubber | flexibility and strength losses caused by ozone, ultraviolet rays and nitrogen oxides |

| Paint | surface erosion caused by sulfur oxides, hydrogen sulfides and nitrogen oxides |

| Fabric | reduced strength and degradation caused by sulfur and nitrogen oxides |

| Paper | embrittlement, degradation and discoloration caused by sulfur oxides |

| Leather | weakening and powdery surface caused by sulfur oxides |

| Ceramic | changing surface appearance caused by acid gases |

| Digital/Magnetic | changing surface topography caused by acid gases or erasure of data caused by electric fields |

Once the main culprit of corrosion is identified, the goal is to determine how to neutralize, minimize or eliminate corrosion from metals in storage. Traditionally, oils have been used to provide a physical barrier between materials and corrosive gases. However, dust, dirt and other particles in the air can contaminate these oils and, in many cases, will start to break the oils down. As the oils evaporate or dry, they leave the sludge or slurry of oxidized oils and these other contaminates behind, and this can and, in most cases, will accelerate corrosion.

Pollution is a major issue all over the globe, but dust is also becoming a rising threat. It is being blamed for impacting snow packs in the Rocky Mountains, as well as accelerating corrosion in China and throughout Asia. For sulfur dioxide to be reactive, dust must be present in the air. Pollution is often worse inside factories, since many recirculate the air. Filters may remove particles, but not gases, and with the recirculation of air, the concentration of those gases increases.

So pollution must be kept from metal items. Oils and coatings have limitations and can actually accelerate the corrosion process if left on for any extended period of time, or if temperatures increase drying and oxidizing. Also, environmental concerns in Europe, where there are newer environmental regulations, push for oil-free solutions. The problem with going oil free is that suddenly the cleanliness of the parts becomes extremely critical.

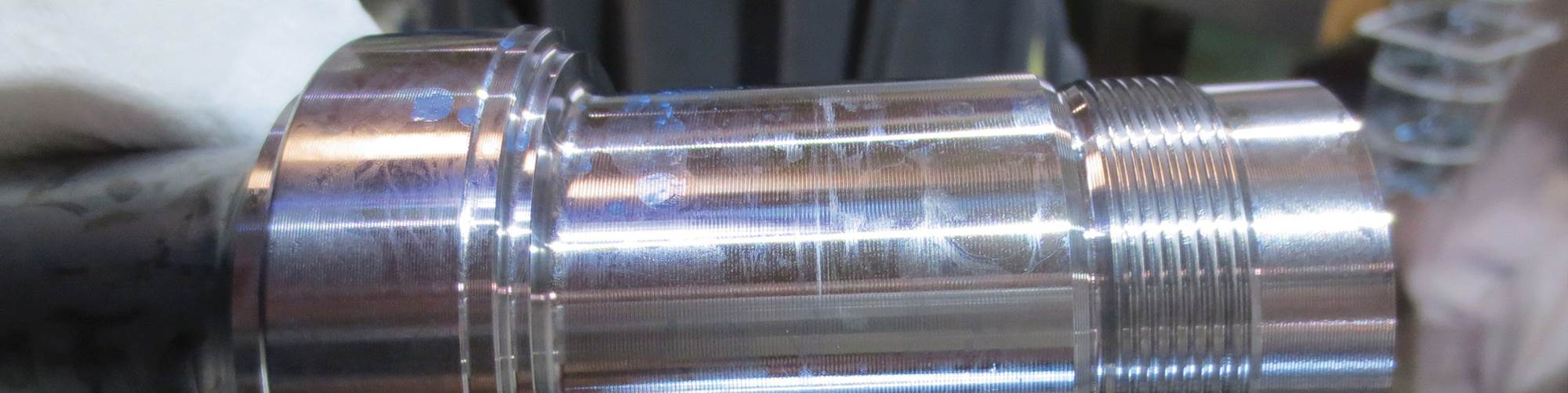

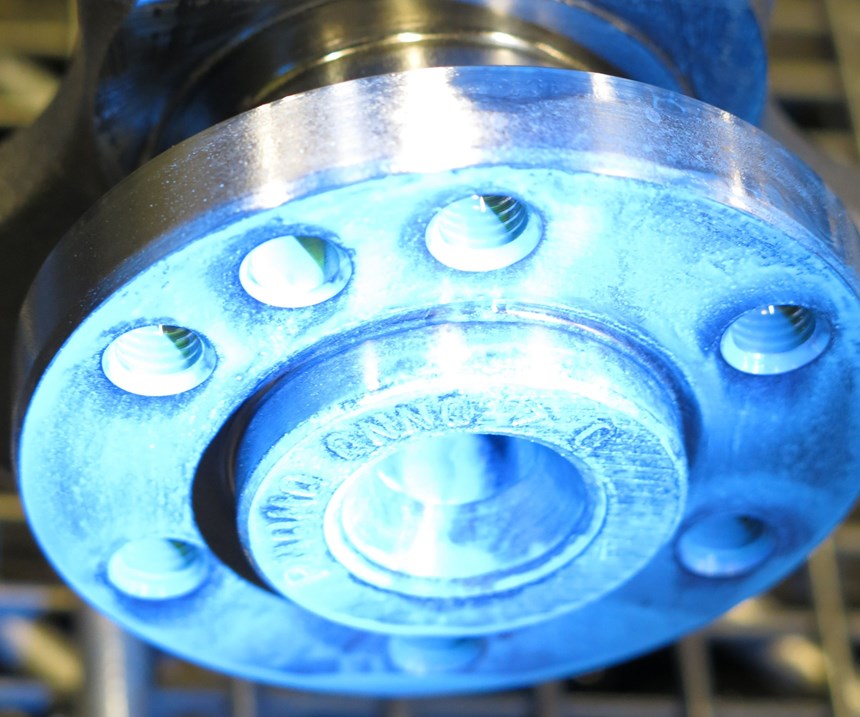

Starting with Clean Parts is Essential

Avoiding corrosion during storage begins with parts that are clean, dry, contamination-free and fingerprint-free. Fingerprints in particular can be highly corrosive, and when metal parts are touched by human hands, oils and contaminants go directly to the parts’ surfaces. Packaging at this point can only help a part from getting worse. It typically cannot overcome contaminated parts; it can simply extend the time until the contamination is either seen as rust/corrosion or hide it until the part is installed in an assembly where it continues to corrode, causing damage to the assembly. That’s why it is critical to wear gloves when handling bare or machined metal.

Almost all corrosion issues that have been investigated over the years have their origin in the cleaning and packing process, either through improper neutralization (pH) of the parts, particulates or fines (chips) in one or more cleaning tanks, cross-contamination of clean parts by the use of dirty rags to wipe them down, trapped water in or on parts, or oil in the compressed air (not using an oil trap on the compressed air lines).

Packaging as Protection

So before packaging, it is important to start with clean parts that are free of fingerprints and other contaminants. Next, determining which bag or film material is the most appropriate for a particular part is critical. Considerations include:

- Temperatures the packaging will encounter in shipment and/or storage.

- Packaging, governmental and/or environmental regulations that will come into play, such as REACH, RoHS, TRGS regulations in Europe, and so on.

- The time it will take to use, close and secure packaging.

- Whether parts are packaged individually or in multiple parts per package. If it’s one piece per package, can the design be changed to pack multiples and reduce packaging costs and environmental impact?

- Shelf life or useful life considerations.

- Personnel, and health and safety issues.

- Total costs of the operation—not only direct costs, but incidental costs, too.

- Safety Data Sheets (consideration of health and safety aspects of all materials).

When packaging, a knowledge of the life cycle of the products being protected should be considered. If the parts can sit for an extended period, packaging materials with short shelf life should not be considered. Also, if the parts or assemblies will be traveling by, stored or used near the sea, care must be taken to ensure that the packaging material isn’t affected by chlorides and provides a good moisture barrier.

A knowledge of corporate, governmental, customer, or environmental regulations that govern recyclability, reusability or chemicals within the packaging materials also is essential. Packaging suppliers should provide, in writing, their packaging materials’ ability to operate in the full temperature range required (-40°F to 160°F, which covers air, sea and truck freight), and meet all appropriate environmental and governmental regulations, as well as their ability to be reused and recycled.

The simple way to look at corrosion on metal is as a straightforward reaction:

- Ferrous metal + corrosive gas (pollution) + moisture = rust

- Nonferrous metal + corrosive gas = corrosion

(Often moisture does not play a factor in nonferrous corrosion.)

To stop corrosion, one or more of the factors on left-hand side of these equations must be stopped or hindered. To stop moisture from entering the packaging, air temperature changes should be minimized. Desiccants can be used to minimize the trapped air inside the package. To attack the metal part of the equations, the surface metal needs to be coated (with oil, for example) or painted; the moisture and corrosive gases must be kept away from the surface. To stop the corrosive gases from spreading to the parts, a hermetically sealed gas barrier that is free from folds, tears and holes, or a reactive gas barrier is needed.

There are four main classes of packaging materials available:

- Passive barrier bags, which tend to be foil bags that cannot be reused, recycled or often even resealed in the field.

- Volatile protection bags use oils, emitter pads or single-pack bags because of proximity requirements.

- Plain polybags with oils or emitters.

- Reactive barrier bags, or gas-neutralizing bags, use finely particulated copper that has been reacted onto the end chains of a polymer (plastic), creating a preferential corrosion site, as well as a reactive barrier to the gases that cause corrosion.

Gas-neutralizing polyethylene plastics are fully reusable and recyclable, contain no volatile chemistry, have no odor, and neither use nor require oils. In addition, these materials have been tested by the German Automotive Industry and have been found to provide as much as 15 years of protection in one bag. Testing by the U.S. military also confirms that the material is effective in the temperature range of -42°F to 160°F.

The world is getting more polluted; this increase in atmospheric pollution can and will accelerate corrosion on your metal parts, so it is critical to isolate those metal surfaces from the atmospheric gases. In determining which packaging material is best for your application, considerations such as environment, cost, and health and safety are crucial.

All metal has built-in corrosion protection; let packaging protect your items until they are required to be used, allowing their inherent corrosion protection to start from the time they are removed from the packaging.

Keith Donaldson is president of Intercept Technology. Visit intercepttechnology.com.

Related Content

Pretreatment of Black Oxide

Having issues achieving a consistent color with the application of black oxide? Start by looking at your pretreatment. Connor Callais of Hubbard-Hall offers advice for troubleshooting your black oxide process.

Read MoreSolvent Versus Aqueous: Busting the Myths

Is aqueous cleaning “greener” than solvent cleaning? Is solvent a more effective cleaner than aqueous? These and many other questions are answered here to debunk the misconceptions that many manufacturers have held onto for years.

Read MoreTop Reasons to Switch to a Better Cleaning Fluid

Venesia Hurtubise from MicroCare says switching to the new modern cleaning fluids will have a positive impact on your cleaning process.

Read MoreFrom Drain to Gain with Smart Wastewater Recovery

Incorporating digital monitoring to maximize performance.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More