As smart technology is installed on more paint lines worldwide, manufacturers gain a more complete picture of their manufacturing operations, helping them improve quality, lower costs, and increase productivity and profitability.

Photo Credit: Dürr Systems Inc.

Industry 4.0 tools of automation, digitization, connectivity, traceability/transparency, and remote process monitoring and troubleshooting — incorporating machine learning — are having powerful impacts on many aspects of the manufacturing environment, and the automotive painting segment is no exception. Benefits achievable when the physical world of manufacturing is connected to the digital world of big data, predictive algorithms, and decentralized data processing and decision making include significantly higher overall equipment effectiveness (OEE), less downtime, fewer errors plus the ability to predict (and fix) issues before they occur, lower energy usage, reduced paint/solvent/water usage, higher productivity and profitability, and concurrent reductions in costs, waste, and lead times. During a period when manufacturers in many regions are struggling to meet staffing requirements, and to manage supply shortages and energy and raw material price volatility, the enhanced collaboration that smart technology makes possible not only within a company but also between a company and its suppliers and customers can make a good company great and a great company a global competitor. What follows are four suppliers making important contributions to this segment.

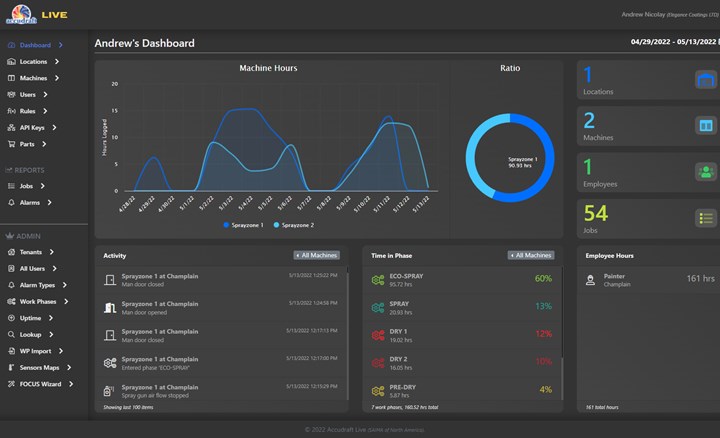

Accudraft LIVE is a mobile-friendly, cloud-based solution for monitoring the performance, costs, and technical metrics of a single paint booth or multiple factories’ worth of paint booths in real time.

Photo Credit: Accudraft

Making Collision Shops ‘Smarter’

Founded in 1981, Randolph, N.J.,-based Accudraft (SAIMA of North America Inc.) is a leading manufacturer and systems integrator for the spray-finishing industry. The company engineers, builds, and installs spray-finishing systems and enclosures throughout the Americas for customers ranging in size from individual collision shops to management services organizations (MSOs) operating numerous facilities. Customers hail from the automotive, commercial truck, aerospace, marine, and rail markets. Additionally, the company maintains and services and conducts onsite emergency repairs for its own equipment and that from other companies. To support its line of paint booth enclosures, Accudraft developed two products that address Industry 4.0 needs for increased connectivity, automation, and real-time data access.

Accudraft LIVE is described as a mobile-friendly, cloud-based solution for monitoring the performance, costs, and technical metrics of a single paint booth or multiple factories’ worth of paint booths. Among the real-time data accessible via the program to streamline the painting process and schedule maintenance are total hours run by any booth, making it easy to track OEE; hours logged by phase, which helps identify system bottlenecks; hours logged by employee; total costs per day to operate a single booth or to compare multiple booths with each other; number of items painted per day, and length of each job. The system also logs uptime and schedules maintenance, then sends reminders when services are due. Replacement parts and filters can be ordered with the touch of a few buttons, helping maximize uptime. As a first-party app, only the end-user/owner can view data and grant access to other users (be it the shop manager, painter, or even an outside supplier).

Accudraft FOCUS is a 15-inch/38-centimeter touchscreen control panel that provides access to online Accudraft LIVE services, including technical support. Users can configure and store up to five separate paint programs and up to 99 different environmental spray settings — including airflow, bake temperatures, multiple flash settings and curing cycles, and cool down — using the FOCUS panel.

“Instead of constantly adjusting for different materials, with our FOCUS panel, the end-user can have multiple preprogrammed settings for different coatings and environmental settings all customizable so products can be finished faster and more efficiently than before,” adds Jeremy Winters, Accudraft content creator.

Coating lines from Venjakob are used to apply liquid coatings and adhesives to a wide variety of substrates, including Class A plastic parts for vehicle interiors. Above, plastic parts undergo contact-free CO2 cleaning.

Photo Credit: Venjakob Maschinenbau GmbH & Co. KG

Eliminating ‘Time Wasters’

Venjakob Maschinenbau GmbH & Co. KG (Rheda-Wiedenbrück, Germany) was founded in 1963. The family-owned company is active in producing machines and lines to apply liquid coatings and adhesives to a wide range of substrates including metals, glass, construction materials, plastics, and wood. Venjakob offers systems engineering, surface pretreatment (cleaning, surface activation), coating (spray, flow/dip) and drying (convection, UV, IR) equipment; and automation (robotics, materials handling). Additionally, Venjakob Umwelttechnik — a member of the Venjakob Group — supplies air-purification systems (rotary adsorber, incineration, energy recovery) that are designed to comply with strict international air-treatment guidelines. The company services a global customer base in automotive, aviation/aerospace, building and construction, electrical/electronics, photovoltaic systems, and marine.

“For decades, our company has focused on designing and building individual equipment and complete lines that are eco-friendly, economical, reliable, and that help eliminate ‘time wasters’ like color changes,” explains Gert grosse Deters, Venjakob executive VP-general industry/automotive. “Our machines are ‘future proofed’ by maximizing current economic efficiency and flexibility of purpose through the use of intelligent controls and digitized communication systems. Since their design is modular, machines can be upgraded with additional functionality later, as new technology becomes available or as additional features are desired.”

Venjakob machines and systems are designed to report all-important process parameters — including wear characteristics, productivity data vs. specified targets, and material flow and requirements — to the user via internal plant ethernet systems and via each machine’s central control panel. Each product’s “recipe” is stored in the system and each color can be prepared in parallel with the current production run, then switched over too quickly. Another example of built-in efficiency is that pallet conveyor speeds are constant and timed to the flash-off/drying sections to achieve appropriate cure and hold intervals. Combined with vertical dryers, this permits space-saving lines that leave room for future expansion by adding length. Also available are optional color-management systems, which allow fast color changes. Venjakob’s color-management system is said to ensure shorter setup times and reduced solvent use.

Among Dűrr’s offerings that support a factory-of-the-future manufacturing environment is its EcoProBooth, a modular automotive spray booth concept providing the reconfigurable, scalable, and flexible setup that allows OEMs to shift between painting a wide variety of vehicle types — from compact cars to sport-utility vehicles — while lowering CO2 emission and energy usage.

Photo Credit: Dürr Systems Inc.

Harnessing the Power of Big Data

Dürr Systems Inc., headquartered in Southfield, Mich., is the North American arm of Dürr Systems AG (Bietigheim-Bissingen, Germany) and is a leading supplier of paint, bonding, and final assembly systems, offers air-pollution and noise control solutions, plus technologies for testing, filling, and battery-electrode coating lines. The parent company was founded in 1896 and is a global leader in mechanical and plant engineering services with expertise in automation and digitization. Dürr supports customers in a wide variety of industries, including automotive, aviation, chemicals, energy, electronics, metalworking, and materials sectors.

“We design, build, and install complete, state-of-the-art paint shops as well as final assembly facilities that are supported by our DXQ, digital intelligence software solution portfolio,” explains Kevin Whitall, Dürr key account manager. “This family of digital intelligence-enabled hardware and software works with robots, ovens, conveyor systems, and coating systems gathering historical data and parsing it with machine learning to detect previously unknown sources of defects and to precisely plan maintenance intervals. It gives manufacturers unmatched flexibility, sustainability, and cost-efficiency.”

The company has introduced a number of complementary modules over the past few years to make paint booths smarter, including DXQoperate, which uses human/machine interface (HMI) level information for database collection, DXQcontrol, an MES/SCADA production-control system, DXQanalyze, which examines data and conducts both equipment and overall plant-quality trending and predictive maintenance, and DXQenergy, which optimizes booth operations to lower energy usage and track CO2 levels.

Is there a way for operators at legacy plants equipped with older Dürr robots or robots from other suppliers to take advantage of these Industry 4.0 tools? “These operators are often limited because most of their system lacks connectivity, and only the latest generation of our own robots feature the right interface for data acquisition, so previously there was no way to connect this equipment,” Whitall continues. He explains that Dürr partnered with Techno-Step (Böblingen, Germany) to develop a solution — DXQequipment.analytics — comprised of an adapter (hardware and software) that provides connectivity to almost all common robots and fieldbus technologies. The system is said to be the first market-ready option using machine learning to increase OEE (overall equipment effectiveness) in the paint shop. “Within seconds, operators can read available sensor and actuator data from their existing plant and integrate the entire spectrum of disciplines — from pretreatment to application to conveyor technology — into a single analytical tool,” Whitall adds.

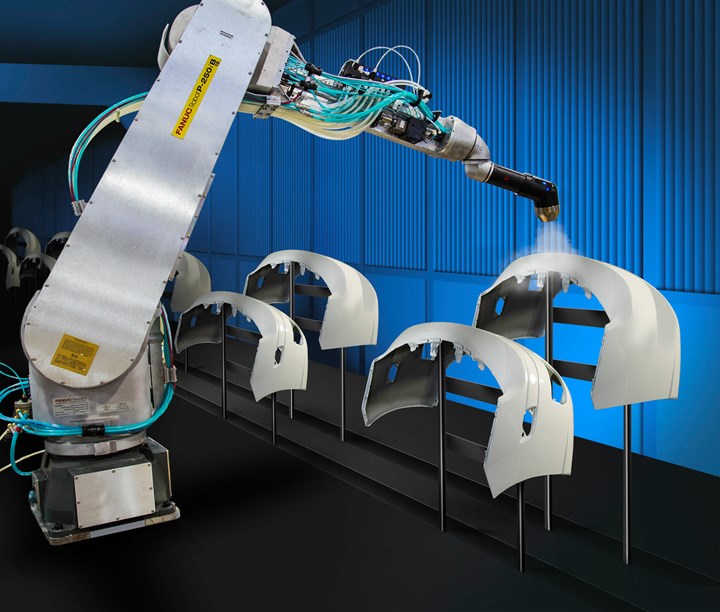

Smart automation technology like robots is not only critical to implementing smart paint booths but also a tool to address current skilled labor shortages and future loss of experienced workers through retirement. To that end, FANUC America Corp. offers a number of robots with varying levels of intelligence supported by three software packages that improve communication, uptime, and process efficiency. Above, a FANUC robot paints automotive front-bumper fascias.

Photo Credit: FANUC America Corp.

Adapting to Workforce Changes

FANUC America Corp. (Rochester Hills, Mich.) has designed and built a wide variety of robots for priming, painting, coating, and sealing since 1982. The company’s paint robots feature easy access, optimal work envelopes, and maximized throughput to help manufacturers improve painting operation efficiencies.

“We offer several versions of our robots with varying degrees of intelligence,” notes Matt Sikowski, FANUC director-paint process and application technical group. “Robotics are key to the future of smart paint booths. Not only do they improve paint quality, color, and appearance, but the robot’s controller can monitor both paint application and robot operation. In fact, we’ve introduced three software packages to this marketplace that strictly rely on the robot and controller software.”

The company’s cloud-based Zero Down Time (ZDT) analytics package improves efficiency and overall productivity by monitoring a variety of robot and paint-application equipment feedback. It also permits staff to work on robots or application equipment during scheduled maintenance while preventing production downtime. FANUC’s Paint Shop Manager improves communication between different shifts in a paint shop and provides a graphical overview of shop status. And Dual Check Safety (DCS) scans robotic speed and position data, immediately shutting motors down when safety concerns are detected. DCS can help minimize paint booth dimensions by limiting space to that solely used for robot motion. Future smart technologies that FANUC is investigating include automatic scan/CAD-to-painting path generation, which will require additional scanning cameras and fast computers to be installed. However, such a system would permit different types of products to move along a conveyor at the same time, enter a scanning area, and have robotic paint paths generated for them automatically.

“Smart automation technology must continue to evolve to address not only current shortages of skilled labor, but also to provide new ways to efficiently address high-mix/low-volume manufacturing,” Sikowski adds. “And moving forward, as experienced staff approach retirement, the skills and experience they’ve built over their decades of work will disappear from the paint shop and be difficult to replace. To address this loss, as new workers enter paint shops, a robot’s intelligence can be used to help train the next generation’s workforce.”

About the Author

Peggy Malnati

Peggy Malnati regularly writes for PF sister publications CompositesWorld and MoldMaking Technology magazines and provides communications services for clients from her Detroit-area office. pmalnati@garpub.com

Related Content

Shedding Light on Surface Inspection

State-of-the-art reflector-based lighting system improves luminosity and ergonomics for surface inspection tasks while reducing energy usage.

Read MoreIntumescent Coating Provides Up to 3 Hours of Fire Protection

PPG Steelguard 951 coating is designed to provide protection against fire and corrosion.

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MoreHenry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreRead Next

Integrating Industry 4.0 Solutions Into Your Coating Operation

Finishers and coaters are adopting automation solutions at an increasing rate. Jacob Fortmeyer offers insights for integrating new technologies into your process.

Read MoreRacking and Conveyor Automation Solutions

Considerations for automating various operations within a finishing system.

Read MoreOutsized Impact: Graphene Nanoplatelets

Nanoscale particles at fractions of a percent greatly improve performance of metal-protective paints, coatings, primers, waxes.

Read More

.jpg;width=70;height=70;mode=crop)