Solving Laser Oxide Issues in Liquid Coatings

Tests show flaking is reflective of the amount of laser oxide on parts.

Addressing laser oxide issues is an ongoing fight in the metal manufacturing industry and the challenge that falls to the finishing industry is to stop coatings from flaking at spots where laser oxide is present.

During the fabrication process, some OEMs use oxygen as an assist gas during laser cutting of mild steel, causing an exothermic reaction that creates heat. This helps the laser cut through the metal, but the process can sometimes result in an oxidized edge that makes it difficult for liquid and powder coatings to adhere to the exposed area.

Vermeer, an industrial and agricultural manufacturer in Pella, Iowa, has been coating its own production parts for the last 67 years, and recently developed a test to measure laser oxide on its parts that were to be coated.

Like other finishers, Vermeer uses carbide dioxide lasers for cutting hot and cold rolled steel with laser oxide. The industry has suggested that it can be removed in many ways—mechanically, chemically or by switching cutting gases. There is no simple way to determine these methods’ effectiveness, nor is there a good way to measure and adjust operations.

Vermeer is an industrial and agricultural manufacturer that has been coating its own production parts for the last 67 years.

Traditional Removal

Driven by customer complaints and personal observations, Vermeer removed oxide mechanically or chemically, and performed maintenance to its multistage washers at the recommendation of its pretreatment supplier, without understanding the chemical life cycle of its acid stages.

Years before any test was developed, the Vermeer paint team spoke with an assembly operator who noticed that paint would flake off a shield when the part was being assembled on the production line. Multiple observations concluded the paint flaked off the edges of the part because the sheet metal flexed during assembly. This was caused by laser oxide loosening and freeing from the metal.

For years, Vermeer informally experimented with flexing different coated metals to see how they reacted under different cutting and washing processes, leading to a need for a more robust and defined process.

In early 2013, Vermeer switched pretreatment providers to Bulk Chemicals, Inc. - BCI Surface Technologies of Reading, Pennsylvania. Specifically, the Vermeer paint team wanted to understand how to better use acid pretreatment in its washer operations to tackle laser oxide. The company sought a better understanding of bath life and what total preventive maintenance processes needed to be put in place to prevent part failures.

Vermeer engineers determined that the amount of material that flakes off is reflective of the amount of laser oxide remaining on the part.

Investigating Behavior

The paint department at Vermeer continued to investigate the behavior of parts in the field and concluded that vibration and other stresses caused the edges of coated surfaces to flake off, similar to what the assembly operator had observed in years past. The team looked into many ways to replicate and expedite the reaction, finally settling on twisting the parts.

The paint team first took scrap-painted parts and twisted them by hand until failure. With some time and numerous trials, one of the paint engineers determined that the amount of material that flakes off is reflective of the amount of laser oxide remaining on the part. To formalize the test, they experimented with different part types, materials and sizes, eventually settling on a 14-gauge cold rolled steel piece for ease of twisting.

Thin-gauge material is commonly used for shields and hoods at Vermeer, so it made sense to move forward with a material of that nature. Over time, the twist test — informally named the Fly Swatter Test — became a commonly practiced test to measure the percent of laser oxide removal.

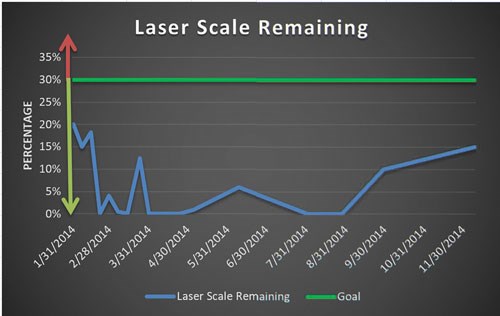

Percentages are tracked routinely to show variables and adjustments to the bath within a washer.

Measuring Flaking

After the paint department began using the test to measure the amount of edge that flaked off versus the amount of initial coated edge, the department determined the percentage as their deliverable metric for keeping records. Tracked routinely, this percentage shows variables and adjustments to the bath within a washer, and captures the impingement effectiveness of washer tips or hand-spray-wand applications.

This has given Vermeer the ability to determine what changes need to be made to its washers to maintain the cycle life and spray effectiveness. The test has also been a key tool when looking to change washer configuration.

If a dwell time, concentration or line speed change is suggested, the impact can be lab-tested before the company ever makes a change. The company has also used the data to look more thoroughly into fiber optic nitrogen cutting on thinner materials to meet customer specifications on corrosion resistance, and into the effectiveness of blasting parts before paint operations.

Vermeer plans to see if the test shows any correlation to the iron removal process on its acid stages.

Andrew Neary is a paint engineer at Vermeer who helped lead the test study. For more information, visit vermeer.com. For information on Bulk Chemicals Inc., visit bulkchemicals.us.

Originally published in the March 2016 issue.

Related Content

TTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MoreIntumescent Coating Provides Up to 3 Hours of Fire Protection

PPG Steelguard 951 coating is designed to provide protection against fire and corrosion.

Read MoreHenry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreRead Next

Taking the (Oxide) Edge Off

Metal fabricators that laser-cut with oxygen take steps to prepare parts better for powder coating.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More