Special Coatings Support Mars Rover

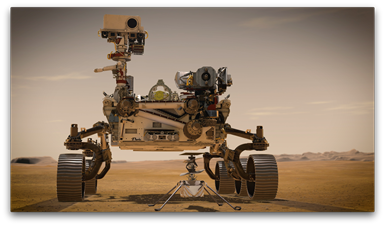

The Mars 2020 Perseverence rover will rely on highly engineered surface treatments to protect it from the extreme temperatures of space and the harsh environment of Mars.

Image | NASA

NASA’s Mars 2020 mission successfully launched on July 30 and is currently on its way to the red planet. Known as Perseverance, the Mars rover’s mission is to search for signs of ancient life and cache rock and soil samples for possible return to Earth.

To protect Perseverance, a special paint job is needed. Chris Salvo of NASA’s Jet Propulstion Laboratory (JPL) who manages the team who puts together the rover’s mechanical subsystem, explains the role the paint job plays in standing up to the extreme temperatures of space travel and the harsh environment of the red planet. A special reflective white paint is used to reflect sunlight and prior to painting, the aluminum surfaces of the rover chassis are scuffed and carefully cleaned to ensure the paint adheres correctly. Detailed masking is required to make sure areas requiring paint are coated precisely and operational surfaces are left unimpeded.

“This very special formulation of paint has to live through all the difficulties of getting to Mars, shaking on the launch vehicle, as well as existing on the surface of Mars in the hot and cold cycles,” Salvo says in a video released by JPL.

Once painted, the rover’s chassis is then baked in a thermal vacuum chamber to remove any volatile materials such as water particles that might be drawn out of the paint by the vacuum of space and cause problems.

Various components within the rover also require special coatings. A proprietary impingement lubricant coating process known as Microseal developed by Curtiss-Wright’s Surface Technologies Division (Parsippany, N.J.) has been used on numerous components for NASA’s Mars 2020 Mission, many within Perseverance’s sample caching system.

Curtiss-Wright Surface Technologies has a long standing relationship with NASA. Microseal was selected for the Perseverance mission because of its friction reduction properties under a wide range of temperatures from cryogenic temperatures to over 1,000° F, and its ability to perform in hard vacuum conditions.

“High performance in harsh conditions typical to space applications demands a reliable solution like Microseal,” says David Rivellini, senior vice president and general manager, Curtiss-Wright Surface Technologies. “The Microseal process outperforms conventional lubricants as it remains stable under extreme conditions and is resilient to shock, radiation, vibration, acceleration and electrical discharge.”

The Microseal process creates an ultra-thin adherent film that fills voids on the surface of components. The film is designed to perform within a vacuum and in extreme temperatures ranging from -423°F to 2000°F (-253°C to 1093°C). The company says the process creates a continuous lubricating surface that reduces friction and prevents galling and seizing. It also dissipates heat, remains stable under extreme environmental conditions, and does not attract contaminant particles.

According to Pierce Cleary, director of business development, Curtiss-Wright Surface Technologies applies the Microseal process to surfaces using a specially designed, patented air tool that mixes micro-size particles. Particles leave the tool at speeds of nearly 600 feet per second, depositing a firmly adherent thin film that fills the surface voids.

“Regardless of the surface geometry of the treated part, once the coating reaches a thickness of fifty to eighty millionths of an inch, no further coating will be accepted,” explains Cleary, “Coverage is uniform on all surfaces the air tool can reach, and the process is burnishable to original dimensions, eliminating the need for special machining or tolerance allowance.”

Due to the complex and proprietary nature of the equipment, Microseal application takes place at one of Curtiss-Wright Surface Technologies’ worldwide facilities. The company inspects incoming parts for cleanliness and freedom from surface defects and closely monitors the entire application process.

The latest Mars rover mission includes numerous new technologies including a robotic helicopter that will mark humanity’s first attempt at flight in an alien atmosphere. Perseverance is scheduled to arrive on the red planet on February 18, 2021.

Related Content

Masking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreConveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreRobots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More