Top Shops: Freedom Finishing, Top Finishing Practices/Performances

Erik Ender prefers to use statistical process controls to let him know how efficient his powder coating and electrocoating lines are humming at Freedom Finishing.

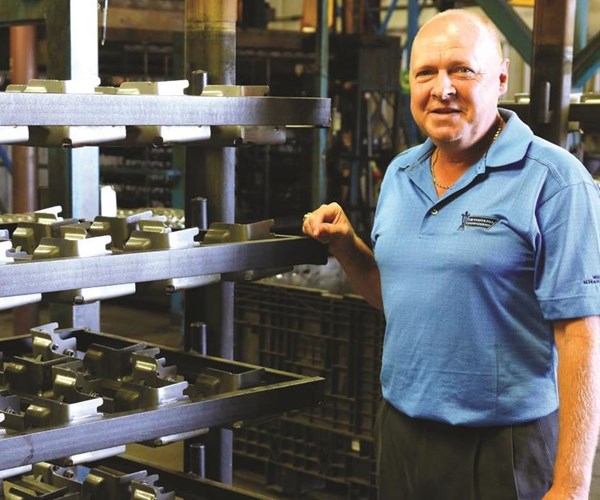

Erik Ender’s tool and die background helped in increasing productivity.

With more than 42 million parts finished each year, Erik Ender doesn’t rely on his instincts to tell him how well his finishing business is operating.

The owner of Freedom Finishing in Benton Harbor, Michigan, prefers to use statistical process controls to let him know how efficient his powder coating and electrocoating lines are humming.

“Our computerized controls monitor every aspect of the process at all times,” says Ender, who started his company in 1988. “The entire plant is designed for smooth product flow.”

Freedom Finishing is recognized in the Top Shops program for its exceptional work in the Finishing Practices and Performance category.

Continuous improvement is a big reason for the success of Freedom Finishing, and Ender says it begins at the highest levels of his management team and focuses on teamwork and customer satisfaction. For years, the company has run a fully-operational ISO quality assurance program that includes ongoing employee participation and training to ensure quality awareness of each of its customer’s specification.

Freedom Finishing is also a stickler for getting coated parts back to customers in a timely—and promised—manner.

“We understand and recognize the importance of on-time delivery to our customers, so we incorporate it as a standard business practice,” Ender says. “Most deliveries are made with our own trucks, so we eliminate any delays that may occur due to a third-party problem. Our plant is about a mile from Interstate 94, which allows us easy access to most delivery routes.”

According to Freedom Finishing’s Top Shop data, the shop had a 99.6 percent on-time delivery rate to its customers. It’s order lead time is at two days, a quick turnaround in a business where all customers want their parts fast.

“In most cases, that means yesterday,” he quips.

Ender says his team takes pride in getting to know their customers well, and therefore become familiar with their products and the way they do business.

“The result is better communication and consistent service,” he says. “Most of our customer’s orders are completed within 1-5 days of receiving product, depending on the availability of the materials required to process the order.”

Ender and his wife, Gloria Ender, started Freedom Finishing in 1988 by just offering powder coating, and in 2001 expanded its capabilities to electrocoating, mainly to diversify their coating requirements to customer’s needs. Gloria is the president of the company, and they now have more than 60,000 square feet of production space in Benton Harbor, where the SPC systems have led to 0.4 percent scrap and rework rates while operating two shifts for roughly 16 hours per day.

Erik Ender’s background was in tool and die and

engineering, which has helped in make their tooling more efficient, as well as increasing productivity.

Freedom Finishing gets most of its work from the automotive, military, appliance, recreation, furniture and heavy truck industries. The company also offers custom racking, masking, packaging and sub-assembly.

“We pay attention to detail for all of our customers,” Enders says. “Their satisfaction is essential to our continued growth.”

Related Content

Masking Solutions for Diverse Applications

Global Mask of Barcelona, Spain showcases its solutions at Paint Expo 2024 in Germany.

Read MoreCan You Afford to Not Use Custom Masking?

Are you weighing the costs of a custom masking solution vs. an off-the-shelf solution? Christy Schulthess of Custom Fabricating & Supplies discusses the overall savings that can be realized with custom masking.

Read MorePowder Coater Leverages Its Manufacturing Mindset for Success

As a former motorcycle manufacturer, this powder coating Top Shop benefits from understanding the finishing industry from a customer’s perspective.

Read MoreHigh Temp Alignment Masking Discs

Designed with printed alignment “target” rings for easy application, PCX-SH Series powder peel green discs from Caplugs ensure pinpoint accuracy when centering over any hole.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)