Top Surface Finishing Innovations of 2016

We look back at the industry’s top new products and services for the past year.

Most of us look forward to the gifts we receive this time of year, but in the surface finishing industry, nothing makes coaters happier than a new or improved product that can increase a shop’s efficiency and possibly raise profits.

Throughout 2016, Products Finishing has been bringing you the latest and greatest in technologies, chemistries and equipment for the plating, anodizing, electrocoating and liquid and powder coating sector, among others.

Each month in our Innovations section in print and at PFonline.com, we’ve educated readers on the newest breakthroughs and updated products from suppliers in the industry. The following is a compendium of the top products that hit the surface finishing market this past year, starting with products that we featured in our Innovations section.

Elcometer’s 415 Thickness Gage Measures 60-plus Readings per Minute

The Elcometer 415 liquid and powder coating thickness gage is designed to quickly measure paint and powder coatings up to 1,000 microns on smooth ferrous and nonferrous metal substrates, enabling users to meet customer specifications and requirements.

“Thickness is not just about appearance. If the paint is too thick in an area where a bolt has to be attached or a screw inserted, the thickness of the paint will prevent the proper fit of those fastening devices and could affect performance,” says Joe Walker, vice president of Elcometer.

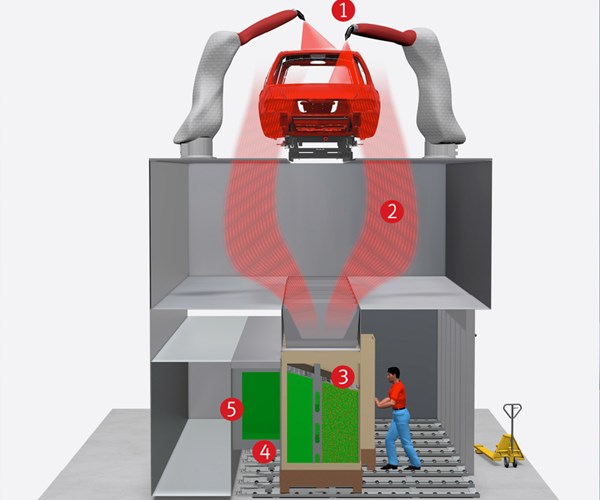

Eisenmann’s E-Cube Simplifies Paint Operations

Paint separation doesn’t always lead to a massive headache and an empty wallet. Eisenmann’s E-Cube is a simple, high-capacity paint separation system that operates without the use of chemicals, water or other additives. The E-Cube uses hybrid filters, consisting of surface and depth-type filters that create a labyrinthine flow path, separating paint-contaminated air.

“One of our customers who has been using this system for three months now says with this system, you ‘set it and forget it,’” says Richard Goelz, Eisenmann’s regional account manager.

Wagner’s 2K Comfort Flex Reduces Solvent Waste

Wagner’s 2K comfort mixing and dosing system is designed for complex multicolor applications. It can process as many as 25 colors and four components simultaneously, and it also enables color changes in less than a minute, giving the user more flexibility for coating process. The company says that the system automatically adapts to changing working conditions and saves up to 90 percent of solvents during color changes.

Axalta’s AR400 Anodic Natura Powder Coating Hopes to Better Anodize Aluminum

In architectural coatings, color mismatch and low abrasion resistance affect product quality and, ultimately, product quantity. The aluminum industry has historically used anodized products in its building applications, but Axalta Coating Systems is hoping to break into that market with its new AR400 Anodic Natura powder coating from its growing architectural color pallet. “The industry needed a coating that would look like anodized aluminum, but outperform it,” says Michael Withers, architectural segment leader for Axalta.

One-Plate EN Bath Solution Streamlines Process

Electroless nickel plating has traditionally required three to four solutions, which sometimes results in imprecise estimations.

“Shops have to purchase chemicals A, B and C to properly maintain an EN bath,” says Michael Feldstein, president of Surface Technology. The company’s One-Plate EN bath makeup and replenishment solution simplifies the EN process by combining three solutions into one.

Binks Diaphragm Pumps Enable Constant Delivery

Binks’ DX70 series of air-operated 1:1 ratio diaphragm pumps is built for direct feed to a single spray gun. The diaphragm pumps include a built-in fluid regulator to ensure constant fluid delivery and are designed for faster color changes and quick refills for less production downtime, the company says.

Gema’s Spray Unit Enables Quick Color Changes

Gema’s OptiFlex2 F spray manual unit is designed for applications that require high film builds or precise and constant powder outputs when using long powder hoses. The unit is engineered with a single-chamber design for a constant and reproducible coating result.

MacDermid Enthone Masco 400 DM Removes Zinc Phosphate Layers

Ron Cucuro, the North America hard chrome and surface finishing product manager for MacDermid Enthone, says the company’s Masco 400 DM is usable in dip spin, rack and barrel processes. The heavy-duty, low-foaming liquid alkaline cleaner is designed to remove zinc phosphate layers as well as oils, grease, soaps and solid lubricants.

“It is specially formulated to minimize the shortcomings of conventional alkaline formula approaches. In addition, Masco 400 DM copes exceptionally well with the buildup of forming lubricants in the bath without creating excessive foam,” Cucuro says. The product can also clean and de-phosphate components in the same step.

Columbia Chemical Black Trivalent Chromium Process Gives Enhanced Metal Distribution

Columbia Chemical’s TriCol BlackJack is its newest process for black trivalent chromium plating, which operates in a mixed sulfate and chloride electrolyte to give enhanced metal distribution across the entire current density plating range. The company says the mixed sulfate and chloride electrolyte enables a significantly faster plating speed when compared to processes that operate in full sulfate electrolytes. TriCol BlackJack baths can provide a range of black trivalent chrome finishes, from a light smoky black to a richer, deeper black.

PPG’s Spectracron 380 Poly-Iothane Series Provides Corrosion Resistance

PPG Industries’ Spectracron 380 Poly-Iothane High-Solids series coatings are two-component polyester polyurethane enamel coatings designed to provide corrosion resistance for metal or over primer-coated metal surfaces.

Caplug’s Rubber Masking Cap-Plugs Protect Copper Tubes

Caplugs’ RMCP-SH series of rubber masking cap-plugs protect a variety of copper inlet and outlet tubes on HVAC compressor units. The cap-plugs are designed to work as both a masking and sealing part, eliminating the need for two separate masks. The company says its styrene-butadiene rubber material can even be resealed after nitrogen charging.

Nordson’s Mobile Spray System Boosts Quality

Nordson Corp.’s Encore HD mobile spray system is designed with Nordson’s fourth generation dense phase spray technology, a system engineered to achieve a highly dense phase spray, a more diluted mixture and anything in between. HD technology delivers a high concentration of powder while using very little air. As a result, the company claims the system provides greater transfer efficiency, less overspray and superior cured finish quality for many part types.

Technibrite HT 1000 Bright Tin Acid Process for Rack and Barrel Plating

Technic’s Technibrite HT 1000 is a new bright acid tin process suitable for rack and barrel electroplating applications. George Federman, Technic’s vice president for project development, says that Technibrite HT 1000 is based on an inexpensive sulfuric acid electrolyte that has an exceptional low current density bright range.

“Most bright acid tin processes can only produce bright tin deposits on parts with complex geometries when their tin concentrations are below 20 grams per liter and their bath temperatures are below 70°F,” Federman says.

Chemetall’s Britemor 921 Cuts Water Consumption

Chemetall’s Britemor 921 is a water-based penetrant for eco-friendly and process-efficient fluorescent penetrant inspection. Its background and wash characteristics enable bright and crisp indications on a range of materials, including ferrous and nonferrous metals, and non-porous ceramics.

Guyson Corp.’s Robotic Blast System Preps Grit Blast Surface

Guyson Corp.’s RB-10 robotic blast system is designed for grit blast surface preparation of gas turbine blades and buckets up to one meter in length. The 60" × 60" finishing chamber of the robotic blasting system features a heavily reinforced 60" × 48" vestibule at the rear to house an ABB Robotics IRB-2600 robot that directs a single pressure-blast nozzle.

Sherwin-Williams Features KEM NISO 8510

Sherwin-Williams’ Product Finishes Division’s KEM NISO 8510 is an isocyanate-free topcoat system that can be color matched in any package size to a range of colors and quickly blended at Sherwin-Williams facilities across North America.

Bale’s Diamond EN Coating Protects Steel and Aluminum

Bales Metal Surface Solutions’ Diamond EN electroless nickel coating with nano-sized diamond particles is designed for corrosion and wear resistance with enhanced lubricity. This coating is available for all industries and has the advantage of being suitable not only for steel tools, but also for aluminum tools.

DeFelsko’s Tester Measures Adhesion Coatings

DeFelsko Corp.’s PosiTest AT-A automatic adhesion tester is designed to measure the adhesion of coatings to metal, wood, concrete and other rigid substrates.

The tester includes a scratch-resistant color touchscreen display with user-adjustable pull rate, pull limit and hold time. The tester is engineered to record the nature of fracture (cohesive, adhesive and glue failures).

Clariant’s Inhibitor Provides Corrosion Protection

Clariant’s Hostacor AL water-dispersible corrosion inhibitor is designed for use in the metalworking industry and has been recognized by the U.S. Environmental Protection Agency for its potential to reduce environmental pollution. This product is designed to inhibit corrosion on steel and aluminum surfaces at low concentrations and pH values around 9.

For more information, visit reliantaluminumproducts.com.

Kyzen’s Line of Solvent Blends Replace Undesirable Solvents

Kyzen introduced a new line of solvent blends designed for high reliability in a wide spectrum of industrial cleaning applications. Designed to replace AK225, nPB, TCE and other undesirable solvents, Kyzen’s clean and green chemistries include Metalnox M6920, Metalnox M6922 and Metalnox M6900.

Atotech’s Zinni 220 Protects Against Corrosion

Atotech North America’s Zinni 220 boric acid and ammonia-free acid zinc nickel electrolyte is designed for corrosion protection and improved throwing power, resulting in higher thickness in low current density areas. Depending on the requirements, this coating can provide bright, semi-bright or matte coatings.atotech.com

Magic Rack’s Hook Organizer, Transport and Burn-off System Streamlines Production

Magic Rack/Production Plus Corp. believes they have solved the problem of hooks falling from racks or the need to untangle the overwhelming mess of hooks in storage bins with its new Hook Organizer/Transport System. Fabrication manager Donovan Dixon says the systems are designed to cut down on manpower and help operations run more smoothly.

“Our goal with this product is to give customers an easy, yet effective, way to streamline their operations and enable them to work more efficiently,” says Dixon.

GFS Curtain Walls and Dividers Protect Against Industrial Environments

Global Finishing Solutions’ curtain walls and dividers are designed for separating and maximizing usable shop space. They can be used for a variety of applications, including dust containment, limited painting, sanding, grinding, welding and woodworking.

Stainless Steel Threaded Line Vac Turns Pipe Into a Conveyor

Exair’s new 303 stainless steel 3/8 NPT and 1/2 NPT Threaded Line Vac Air Operated Conveyors convert ordinary pipe into a powerful conveying system for parts, scrap, trim and other bulk materials.

Its small size makes them perfect for fitting in the cramped spaces and tight confines of many production lines. The Threaded Line Vac is designed to attach to plumbing pipe couplers, sanitary flanges and other pipe fittings, making it easy to build a complete system using ordinary pipe and fittings. These new sizes of stainless steel Threaded Line Vac air operated conveyors make it easy to sample gas streams, sample grains or other ingredients, move small parts, or transport scrap or product out of small spaces.

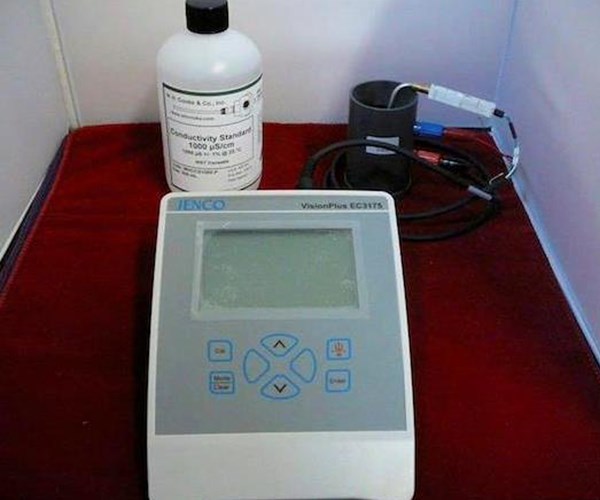

W.H. Cooke PPG-CT55-Kit-Rev2 for Ecoaters

W.H. Cooke and Co. has released the PPG-CT55-Kit-Rev2, featuring the Jenco 3175 benchtop conductivity/CTS/temperature meter, the CT-55 series conductivity cup and buffer solution. The CT-55 series conductivity cup is an excellent choice for customers that need a durable, high-range conductivity sensor for difficult applications such as paint, viscous liquids or other difficult samples.

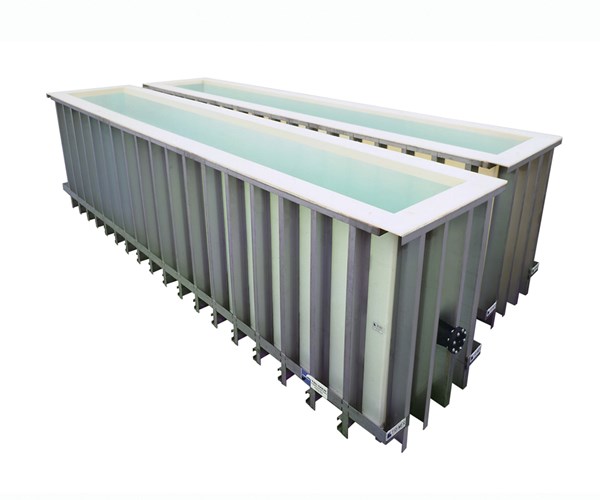

Tri-Mer Offers Tanks Over 100 Feet

Tri-Mer Corp. offers fabricated process tanks from polypropylene, PE, PVC, CPVC, mild steel and stainless steel in sizes that exceeed 100 feet in length. The company specializes in 100 percent co-polymer and homopolymer polypropylene that are rugged, long-life materials that Tri-Mer sais won’t delaminate or embrittle, even with exposure to aggressive chemicals over long periods

of time.

Tri-Mer tanks provide exceptional resistance to strong acids and alkalis—even at higher temperatures—and are custom engineered in rectangular, circular and custom shapes, with fume hoods, cone bottoms, agitation, and material handling.

The company also specializes in tanks with requirements for special access, constraints on height or footprint, exceptional capacity and tanks requiring robust structural support.

tri-mer.com

Global Finishing Solutions LLC

Magic Rack/Production Plus Corp.

Nordson Corporation, Industrial Coating Systems

Originally published in the December 2016 issue.

Related Content

Trivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreLiquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreA Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)