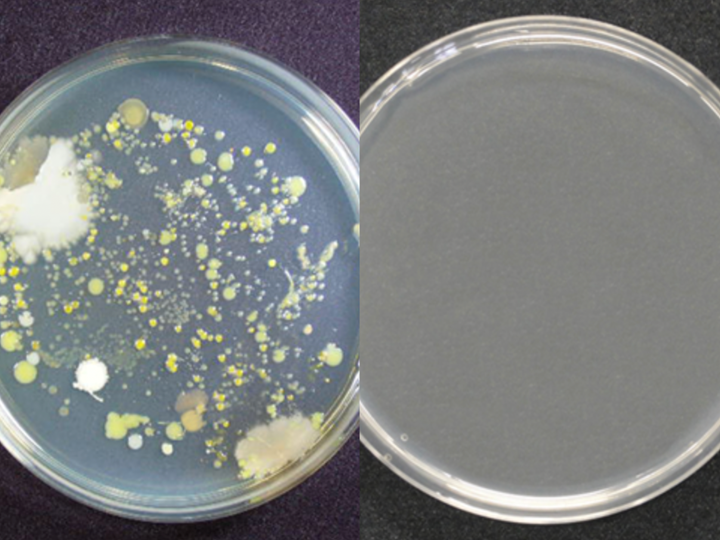

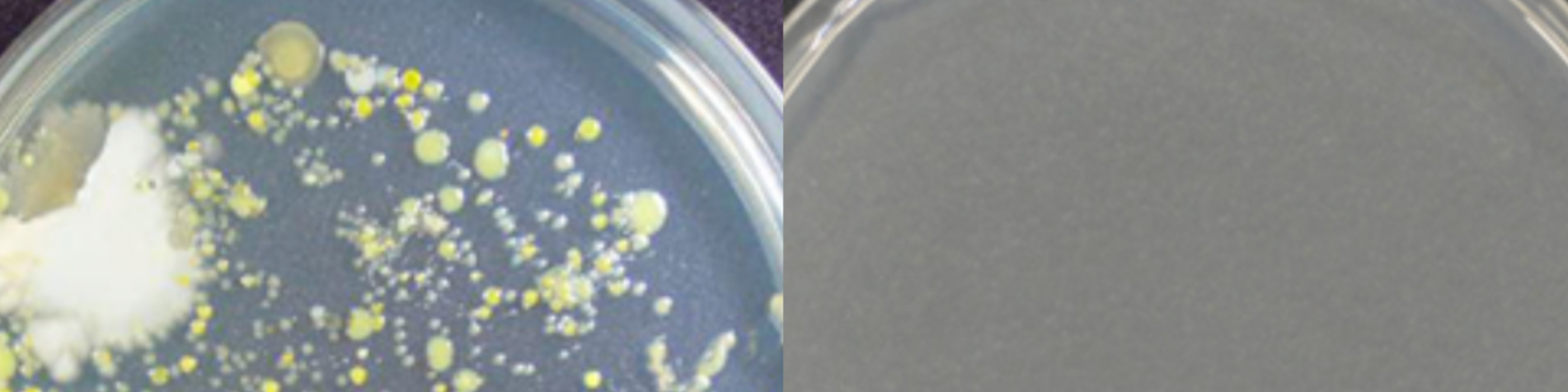

These samples show the bacteria culture growth agar plates with and without silver ions, indicating the benefits of silver-ion based antimicrobial agents. Source | Vitracoat

As the world works to recover from the COVID-19 pandemic, our collective awareness of spreading germs is at an all-time high. Every surface is subject to suspicion. From railings to countertops to packages, every surface we touch is a potential danger. A Fed Ex package was recently left at my door and I left it on the porch overnight and kicked it into the house the next morning so I wouldn’t touch it with my bare hands. I’m sure many of you have been taking similar measures, which just a few of months ago would have seemed extreme. The coronavirus pandemic has forced everyone to become more aware of what we touch and what we come in contact with on a daily basis. Perhaps this heightened awareness can help to prevent future spread of germs.

Surfaces are everywhere and avoiding them is nearly impossible. We eat at a tabletop, our food is stored on shelves, to open doors you have to grab a handle, to fill your gas tank you have to grasp a fuel pump nozzle, and we walk everywhere. Simply walking exposes your shoes to all manner of microbes, which you then track and spread wherever you go. No matter the surface, its impossible to know who touched it last, what is on it and whether or not it is harmful. And while cleaning is vital, at the end of the day, there is no one answer to ensure that surfaces are clean and safe.

One solution that may help play a role in stopping the spread of germs are antimicrobial coatings. The technology has been on the market for more than a decade and the antimicrobial coatings global market is a billion-dollar industry, exceeding USD 3.2 billion in 2019.

While there are numerous antimicrobial coatings on the market with different formulations, those based on silver seem to be the most effective. One company, Vitracoat (Elkhart, Ind.), whose VitraGUARD line of coatings is designed to assist with this problematic paradigm. The technology is based on silver, a natural antimicrobial that has been shown to be effective in killing over 650 strains of bacteria, yeast, fungi and molds.

“What our research has found is that by introducing a specific additive in a predetermined amount to the powder coating formula, the coating and therefore the coated surface may help to protect the consumer,” says Steve Houston, Director, Sales and Marketing for Vitracoat.

Vitracoat’s VitraGUARD is a proprietary technology where a spherical silver-ion based ingredient that is homogenously incorporated into the coating. Silver -ions are activated with moisture and then attach to the microbes and begin disrupting the metabolism, respiration and reproduction of the microbe. By eliminating the microbes’ ability to grow and reproduce, the spread of bacteria is greatly diminished or eliminated. Efficacy tests have shown in most cases more than 50% reduction in the growth on surfaces.

Vitracoat says its antimicrobial agent is effective against a broad spectrum of gram-positive bacteria, like Listeria and Streptococcus and gram-negative like E. Coli and Salmonella bacterium. While there is no evidence to suggest that antimicrobial coatings have any affect on viral outbreaks such as COVID-19, the technology may help cut down on the amount of exposure to a host of germs encountered on a daily basis.

“It is very important that we are completely clear and state that to date, this technology has not been proven to impact COVID 19 in anyway, however the benefits still remain,” says Steve Houston.

Vitracoat says can incorporate the additive in virtually any powder coating without changing the appearance of pigmented products and with little change in the application.

“The idea is to give the consumer a product that looks and feels the same but offers an additional sense of safety,” says Houston. “Being safe is the message and considering all tools and technology available to that end is the goal.”

Related Content

Masking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

Read MoreSelecting the Right Outdoor-Durable Powder Coating

The powder coating industry offers an array of chemistries to provide an excellent match to the manufacturer’s expectations for outdoor durability.

Read MoreConveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreTTX’s Automated Conveyor Carrier System Offers Wireless, Flexible Operation

ACC system designed for reliable, consistent point-to-point movement of everything from small to heavy parts.

Read MoreRead Next

Are Antimicrobial Powder Coatings a Silver Bullet?

Antimicrobial powder coatings that feature silver as a key antimicrobial ingredient are raising the powder coating industry to new heights.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;maxWidth=300;quality=90)