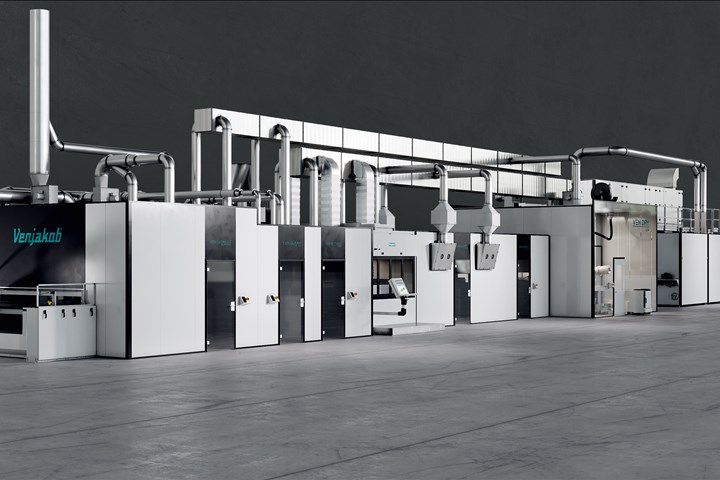

Coating line for plastic components with modular design, individually adapted. Here with loading and unloading station, CO2 cleaning, high-performance dedusting/ionization, gas flaming, spray-coating, evaporation zone, IR drying, UV curing; circulating air drying. Photo | Venjakob

Venjakob Maschinenbau GmbH Co. (Rheda-Wiedenbrück, Germany) recently released a case study for a modular coating line concept for plastic components that allows the individual machines to be equipped according to requirements, which can be upgraded with additional functions at any time.

The overall system concept is presented as an example of what modern coating lines can achieve. Plastic parts are painted and dried using wet paint systems. The individual machines — from pre-treatment to painting and drying — were equipped with optimized individual equipment and assembled to form a complete finishing line. Traditional 1-component and 2-component solvent and water-based lacquers and UV lacquers can be used.

The complete system can be configured with the following modules:

- Cleaning modules: CO2-cleaning, high-performance dedusting/ionization

- Activation modules: flame, plasma, UV

- Coating: Spray booth

- Drying: flash off zone, infrared dryer, UV curing system, circulating air dryer, cooling zone

- Fresh air supply: supply air system, full air conditioning

- Exhaust air purification: exhaust air purification systems RTO, TI

The planning of the production line was focused on high variability in the use of the machines used. Particular focus was given to the spray coating process and the advantages of the modular design are evident in the spray coating machine. Color changes, can be carried out simultaneously to production with minimal transport downtime.

The systems central control panel enables a flexible interaction of all individual components. Each product receives its own recipe. Each color can be prepared parallel to the running production and quickly activated.

The system allows for the collection of data about the processes, the productivity of the system, and wear and tear, enabling consistent production quality, logistical planning and plant maintenance.

Related Content

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreCuring Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

Read MoreCobot Enters Paint Industry With Safety at the Forefront

This collaborative robot is the first explosion-proof solution for the powder coating and paint arena that meets the U.S.’ stringent safety requirements. Its lead-through teach programming and tablet control are especially appealing to small shops with little proficiency in robotics.

Read MoreHenry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More