What’s in a Burr?

An unclear definition has led to an industry standard for classifying burrs.

A burr. What is it? How do you define it?

An unclear definition of burrs was a problem the finishing industry faced for many years. Every manufacturer and industry segment defined a burr differently. That was a problem for shops trying to provide deburring solutions and for customers trying to figure out what solutions to look for.

How could you provide a standard solution to a non-standard problem?

One solution to this problem was development of a burr standard that was easy to understand and apply in the field. A team of engineers began working with manufacturing and distribution channels to develop such a standard for classifying burrs.

By looking at typical burrs on various materials and documenting the similarities and differences of each, the team identified five types of burrs. The characteristics of each type where defined and documented, and five standard burr classes were developed. This standard was quickly adopted by manufacturing companies and embraced by distribution channels.

Five Burr Classes

The table on the next page shows the five standard burr classes that were developed. Burrs can form on all types of materials, but in the finishing industry, we typically encounter burrs on steel, aluminum, ductile iron and titanium.

Class 1 burrs are also known as “micro burrs.” These burrs can only be seen with magnification and look like sharp edges to the naked eye.

Class 2 burrs are also small burrs, sometimes called “feather burrs.” These burrs are able to be seen without magnification and can sometimes be scratched off of an edge using a fingernail.

Burrs on steel and aluminum typically are classified as Class 1 or Class 2 and can be removed with standard silicon carbide advanced technology brushing (ATB) brushes.

Class 3 burrs are well-attached burrs that are small in nature but require significant, mechanical finishing force in order to be removed.

Class 4 burrs are well-attached burrs that are large in nature, have significant route thickness, and have a larger and stronger attachment point than Class 3 burrs.

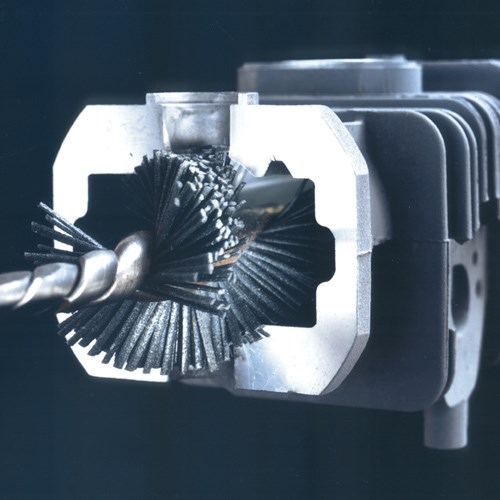

Class 3 and Class 4 burrs require a more aggressive deburring product. Some success can be achieved with short-trim wheel brushes. Adding bridles to disc brushes also helps control flare and shortens the trim of the brush to make in more aggressive in steel applications. However, tackling well-attached burrs on exotic materials such as hardened steel, Inconel, Hastalloy, stainless steel and titanium requires a solution such as ceramic grit with a sharp, jagged grain that provides a deeper cut and removes material faster.

Class 3 and 4 burrs require finishing products that can stand up to the job and help shorten cycle times as well.

Class 5 burrs are commonly known as “extruded burrs” and are not actually burrs but a deformation of extruded material caused by drilling. These deformations typically indicate a problem within a process, whether it is too high of speed in drilling or in material feed. They appear as very large burrs that extrude from the base material. The extruded or displaced material requires preconditioning with a chamfer or carbide cutter to remove the material. Preconditioning will leave the residual burr that is removed with brushing.

Two Questions

With an industry standard now in place, application engineers can simply ask two questions to get an idea of the manufacturer’s needs: What material is the manufacturer working with, and what burr class is it trying to remove? With these answers, the finisher can quickly offer appropriate solutions. In addition to establishment of the burr classification system, other finishing concerns related to deburring include integration with automation, longer product life, aggressive/compliant brushes, and deburring without changing surface finishes.

Integrating Automation

Growth in automation in general has been a trend in manufacturing and finishing for a significant amount of time, however, it is becoming more amplified as robotic applications and automated processes are being used more frequently. Automation provides accuracy and repeatable quality, day in and day out, and helps finishers attain tighter tolerances and higher production demands.

Finishing products can be integrated into robotic cells that mimic the movement of the human hand. CNC machines and custom deburring machines are also necessary. These needs not only impact brush design, but also the mounting capabilities of standard and customized machines.

In-machine deburring has become a new standard in the aerospace industry. Aerospace manufacturing is adopting the automotive production style and is doing away with hand deburring. New aerospace standards are creating the need for much higher precision in deburring, tighter tolerances and exact production quantities. Automated processes are being put in place to keep manufacturing in-house and maintain tighter process control.

Product design flexibility can aid in automated finishing with the ability to add flow-through coolant. Coolant provides an ideal working environment for advanced brush products and also offers many finishing benefits for the manufacturer. Coolant keeps the nylon filament rigid for consistent finishing and aids in achieving a finer surface finish. Coolant also lowers the risk of warping and distorting parts, especially in applications where smaller or thinner parts are being processed.

Longer Product Life

Brushing is now mainstream in many applications, and users are seeking products that offer a long service life. Tough and durable finishing solutions are a necessity, and this is why more brush suppliers are developing advanced technology lines that feature tougher nylon filaments that are not susceptible to premature fracture and that hold their grain longer, resulting in longer filament and overall brush life.

Product life directly impacts the user’s bottom line. When looking for a finishing solution, manufactures should not necessarily seek out the least expensive product, but one that will provide the best value, including a long service life. The ideal finishing solution will shorten cycle times and provide a long brush life.

Aggressive/Compliant Brushes

Finishers today are pushing their tooling harder and using in-machine deburring rather than secondary machines to precondition larger burrs on materials such as ductile iron and compact graphite iron. In response, most brush suppliers have developed products that are both aggressive and compliant. Newer filaments can do what the regular rectangular filaments cannot: conform to a complex shape. These new brush lines include products that work well in removing large burrs on Inconel and other high-nickel materials typically found in the aerospace industry.

Maintaining Rough Surfaces

Certain industries actually run into problems with surfaces finishes being too smooth after deburring with an advanced technology brush. For example, in the automotive industry, if the surface of some finished parts is too smooth, gaskets will not seal properly. This translates into a part that will not perform correctly. Certain parts need to have the same surface roughness or even a rougher surface after burrs are removed as before. Stainless steel wire disc brushes are ideal for deburring in these applications because they remove the burrs, yet maintain or roughen the deburred surface.

In order to help finishers receive the best overall value, brush makers and products finishing solution providers must be responsive to the customer’s needs and set standards for finishing products that help reduce cycle times, provide an excellent return on investment and cut consumable costs.

Mike Akuszewski is a field application engineer at Osborn/JacksonLea.

For more information, visit osborn.com.

Related Content

Blasting Beads Made of Lead-Free Natron Glass

SwarcoBlast blasting media are made for use in a multitude of surface refinement applications.

Read MoreLapping, Polishing Film Maximizes Strengths, Maintains Flexibility

Dia-Strip and Dia-Sheet film from Titan Tool Supply has a distinct construction that the company says makes it durable while remaining flexible, bendable and formable.

Read MoreHaving a Blast: Best Practices for Media Blasting

5 considerations for media blasting as surface preparation for coatings.

Read MoreBest Practices for Blast Room Maintenance

A high-quality blast room is a large investment. Brandon Acker of Titan Abrasive Systems discusses proper care for your blasting equipment.

Read MoreRead Next

Defining Deburring and FOD

Burrs and foreign object damage (FOD) are considerations that are increasingly critical as precision machined parts are engineered from more challenging materials and to demanding geometries and applications.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More