Why Temperatures Change Between Liquid Circulation System and Point of Application

Mike Bonner with Saint Clair Systems says a specialized control system is required to eliminate temperature changes between a liquid circulation system and point of application.

Q: Why does my temperature change between my circulation system and the point of application?

A: The modern paint shop is a maze of pipes and tubes carrying paint all over the place! Some of these circulation systems even have temperature control systems designed to make sure that the paint temperature is controlled as it is circulated. So why is paint temperature still such an issue?

As long as the paint is circulating in the system, though it may be exposed to pressure, shear and friction, it is still relatively safe; and every time it passes through the heat exchanger (on every loop through the system) it comes back to the set point temperature, so it’s relatively stable. Consequently, it makes sense that it should be stable when it is applied, right?

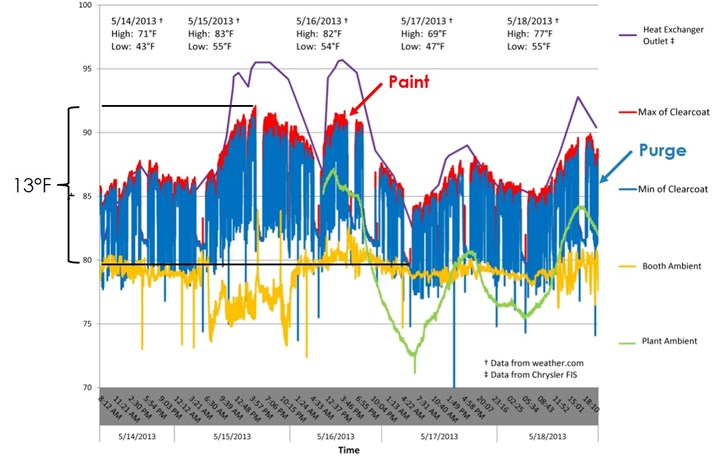

We’ve worked with plenty of these systems and done plenty of measurements at the point of application and, as it turns out, this is rarely the case. In fact, this chart from a major automobile manufacturer with a temperature control system in the circulation loop shows a 13°F variation at the point of application over the course of just five days in mid-May.

5-Day Paint Temperature

So, how can this be? The problem is, in order to get to a part, the paint has to leave the safety of the circulation system and travel to a gun or bell to be dispensed. That’s where the fun starts…

When the paint leaves the circulation system, it travels through progressively smaller tubing until it reaches the gun or bell. There will be pressure regulators, flow meters and color changers along the way. All along the path, the volume of paint gets smaller and it is in contact with more and more surface area. This may be stainless steel, Teflon, nylon or any of a host of other materials. And the paint may slow down. In some instances, it may stop altogether for periods of time. These are perfect conditions for temperature exchange. In fact, the principle behind a shell and tube heat exchanger is to reduce the volume, increase the surface area contact and extend contact (dwell) time by temporarily reducing velocity — all by splitting up the paint flow into a bundle of smaller tubes.

The path to the booth may be down from the truss level overhead, where it is exceedingly warm, or it may be up from the basement or a trench, where it is cool. Regardless of where it’s coming from on its way to the booth, it is exposed to an ever-changing ambient. Changing from day-to-night and season-to-season, this is where the change in temperature becomes consistently variable and totally unpredictable.

“But my pipes are insulated.” We hear this a lot. And insulating is a good thing. But the reality is that insulation is a tool that slows temperature change; it doesn’t stop it. That’s why insulating your house doesn’t obviate the need for a furnace! Furthermore, we generally only insulate the supply lines (ostensibly to save cost) and the circulation system. We generally ignore the drops and all the myriad components between the circulation system and the point-of-dispense. It is understandable, given the level of complexity involved in insulating the twists, turns and devices in the path. Yet, as we have already noted, this is where the bulk of the temperature change takes place.

Centralized temperature control systems designed to protect and control the paint as it flows through the circulation system are widely used and can be a very important tool in the overall control of the process. But they are ill-equipped to address the variations at the point-of-application — where the actual business of creating a uniform, high-quality finish is performed. For that, a specialized control system is required — a system that can eliminate those variations that are introduced between our carefully controlled circulation system and our applicator.

Mike Bonner is vice president of engineering and technology at Saint Clair Systems. Visit viscosity.com

Related Content

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreShedding Light on Surface Inspection

State-of-the-art reflector-based lighting system improves luminosity and ergonomics for surface inspection tasks while reducing energy usage.

Read MoreHenry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreCoatings Plant Evolves with Market Trends

Expanding its focus from exclusively serving the RV industry, one of this company’s stand-alone coatings plant has successfully extended its services to additional markets.

Read MoreRead Next

Education Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More