Fabric8Labs’ Electrochemical Additive Manufacturing (ECAM) process makes it possible to realize complex geometries for better cooling of semiconductor chips, among other applications — like this 80% gyroid infill cold plate. Photo Credit: Fabric8Labs

“About 80% of thermal management solutions in data centers use air-cooling today,” says Ian Winfield, vice president of product and applications at Fabric8Labs. “40 to 50% of their total power consumption is going toward removing heat.”

The problem of keeping this critical technology cool will only get more difficult to solve as chips continue to become increasingly powerful. Already, chip manufacturers and integrators are running up against the limits of what air cooling systems can do. The next wave of data tech will require a different solution — and Fabric8Labs is betting on liquid cooling enabled by its particular form of 3D printing, Electrochemical Additive Manufacturing (ECAM). I visited Fabric8Labs’ pilot facility in San Diego, California, in September of 2023 to learn how the proprietary process works and the advantages it brings to this challenge.

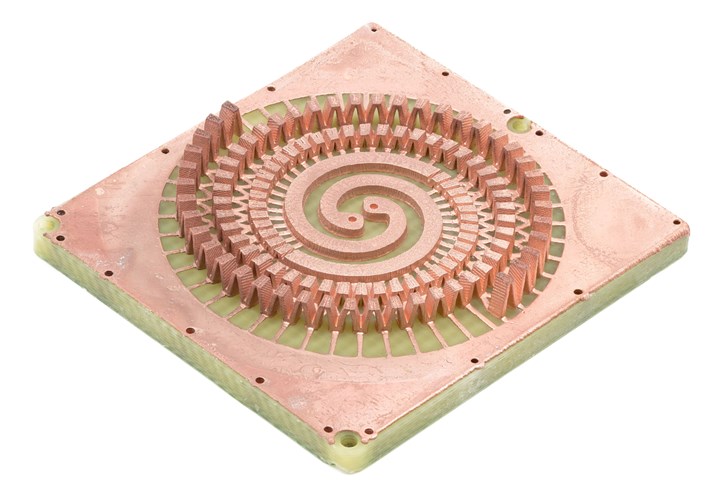

This cold plate illustrates another of ECAM’s advantages over skiving: the chance to create these plates in just the right shape, including round ones. Photo Credit: Fabric8Labs

Today the semiconductor industry depends on cold plates and other cooling devices that are typically manufactured through forging or through a process called skiving. In the latter, a flat piece of metal, often copper, is subjected to a shaving-like operation which peels up thin pieces of material, bending them into fins that dissipate heat. The process is confined to producing straight, regular lines of these fins that can be made in just one direction, and is limited in terms of the geometries that it can fill with these features.

But beyond the manufacturing challenge, thermal management devices made this way are limited in their surface area and the amount of cooling they can deliver. 3D printing provides a means of not only increasing surface area and roughness for better heat dissipation, but also a path toward complex liquid-cooled plates and heat exchangers that offer significantly improved performance.

Introducing Electrochemical Additive Manufacturing (ECAM)

The ECAM technology proprietary to Fabric8Labs is particularly well-suited to these thermal applications. ECAM borrows elements of other manufacturing methods to produce metal parts in an unusual 3D printing process. Rather than metal powder or wire, ECAM uses electroplating solution — a water-based bath carrying copper ions — as its feedstock. The precise formula is a bit different than what might be found in a plating line, but the ingredients are readily available because of this shared chemistry.

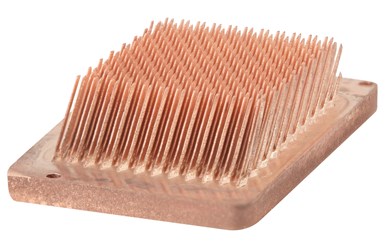

Rather than apply the plating uniformly to a preexisting part, however, ECAM builds three-dimensional parts using display technology with a method similar to digital light processing (DLP) 3D printing. Instead of light to cure resins, ECAM activates electrical currents pixel by pixel, causing the copper ions in the solution to form atoms in those precise locations. The metal is deposited atom by atom, making the process capable of producing extremely fine features, with typical layer heights today in the range of 10 to 50 microns.

An ECAM build typically takes just a few hours depending on part height and geometry; for example, one printer can make a batch of four cold plates in about three hours. After printing, parts are rinsed with deionized water inside the machine; run off helps to replenish the fluid levels and maintain the solution. In many cases parts are complete after removal from the reusable build platform, but they can also be plated, passivated or machined as needed.

Advantages of ECAM

The level of detail and complexity possible, coupled with pure copper as the initial material offering, have combined to make ECAM a promising offering for small, detailed cold plates, heat exchangers, RF antennas and similar devices.

When Fabric8Labs’ three cofounders developed the technology, the goal was to make metal additive manufacturing easier, and ECAM brings a number of benefits over powder or wire-based processes. Compared to these processes the ECAM machines have a lower power draw which arguably makes the print process more sustainable. The electrolyte solution used as feedstock is safer and easier to handle than metal powder, and can be printed without the need for a full enclosure or inert gas. The room temperature process improves operator safety as well. And, the liquid feedstock offers benefits for 3D printing at scale (more on this in a moment), including the opportunity to supply multiple printers from one large, centralized tank where the proper material levels are maintained at all times.

The relatively simple design of the machine has made it easy for Fabric8Labs to quickly scale to a line of about 20 printers, and the company has plans to grow its production facility to 250 in 2024. That rapid growth reflects the opportunity that the company sees in the semiconductor field and its aim to compete directly against conventional manufacturing based on cost for the solutions it can provide.

RF devices like this spiral geometry are another promising application for ECAM. Photo Credit: Fabric8Labs

“The electronics value chain from silicon to PCBs is still learning about AM and how to think about it,” Winfield says, “but the economics just don’t work with powder-based additive manufacturing. ECAM provides a unique possibility for thermal, RF and electrical applications through high resolution features, the use of pure copper, and the fact that this is a room-temperature process that can print onto a wide variety of substrates.”

Cold Plates Made with ECAM

Cold plates and similar heat exchangers represent a particular area of interest for Fabric8Labs. Compared to conventional manufacturing of these items, the ECAM process requires no tooling or consumables such as cutting tools, uses cheaper feedstock, and demands very little human interference.

All of the cold plate examples I saw during my visit (including this one with a 50% gyroid infill) featured regular, repeating lattice geometries. That doesn’t need to be the case, however, and Fabric8Labs sees opportunities in the chance to customize the plate to its chip. Photo Credit: Fabric8Labs

But the primary reason the company believes semiconductor manufacturers and OEMs will choose ECAM is for the design and performance benefits that are possible when 3D printing is combined with advanced design and simulation software. Designs created with topology optimization software enable ECAM to deliver complex structures with much more surface area than a skiving process could. Whether air or liquid-cooled, plates built this way have the potential to deliver better thermal resistance, control pressure drop, and ensure temperature uniformity across the chip.

This last point — temperature uniformity — actually involves some customization for the particular use case, because chips themselves don’t operate at consistent temperatures.

“A system will only work up to its hottest spot,” Winfield points out, which makes these hot spots the limiting factor for any cooling system.

With ECAM, however, Fabric8Labs can use the heatmap for that specific chip as an input for the design of its correlating cold plate. Gyroids and other structures can be placed exactly where needed to compensate for that heat, and even graded across the plate to optimize performance everywhere. Cold plates could even be customized for each chip, something not feasible with conventional manufacturing techniques.

Transformative High Performance with 3D Printing

The geometric and customization benefits of ECAM-produced cold plates are not yet being realized by most Fabric8Labs customers today. The company is still in a mode of growth and preparing for the scale that is coming. Its 80-plus member workforce is currently distributed between building the next generation of machines and developing applications for customers, most of which are proof-of-concept components intended for high-volume production.

It's a tricky balance, according to Anasuya Adibhatla, director of global business development. “The business model will be producing parts, not selling machines,” she says. “This is the pilot facility for building machines, and the location for application development. We’ve been developing both at the same time, and soon we need these to intersect.”

While the cold plates that Fabric8Labs produces are only a centimeter or two tall, the ECAM technology can be applied to taller parts and delicate geometries like this pin fin heat sink (top) and these spirals. Photo Credits: Fabric8Labs

Once that intersection comes, however, Fabric8Labs is prepared to scale rapidly. The company has already begun moving into its pilot production facility located nearby in San Diego and plans to have this location up and running with 250 ECAM machines in 2024. That will provide enough capacity to begin manufacturing semiconductor cold plates at scale, as well as other items such as RF devices. In this space, too, the geometric possibilities with ECAM can open functionality not possible today, such as three-dimensional antenna designs that allow communication systems to make use of broader bandwidth. Other opportunities might also be found in the medical device industry and automotive, among others.

“We’re in transformation from R&D to becoming a high-performance manufacturing company,” Winfield says, noting that Fabric8Labs will be pursuing ISO certification and other production-related credentials soon as well.

As production takes off with the first thermal management products in pure copper, the company plans to explore applying ECAM with other kinds of materials such as copper and nickel alloys, tin, platinum, palladium, tungsten, and gold. It is also demonstrating the capability of using ECAM to print directly onto silicon sputtered with copper, eliminating the current need for a thermal interface material to sit between the cold plate and the chip.

While the company does see potential wins in terms of cost and speed for parts made through ECAM versus conventional processes, the primary benefit Fabric8Labs aims to bring is enhanced performance.

“We have to provide a meaningful performance gain for our customers,” Winfield says. With the growing importance of systems like data centers, OEMs and operators are looking more and more at the total cost of ownership for equipment, and that includes the capital expenditure as well as cost to operate. Chips that stay cooler will run better and last longer, saving money over the long term. While the potential for liquid-cooled, 3D printed cold plates could be transformative, even small advances are worth making.

“For thermal applications,” Adibhatla says, “even one degree of cooling is a big deal.”

Related Content

Advantages to Pumped Eductor Agitation

Not all agitation methods are created equally. Pumped agitation with eductor nozzles can improve process tanks and quickly show a reduction in operating costs while keeping staff safe, following environmental legislation and preventing pollution.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreTroubleshooting Alkaline Zinc

One of the most common problems that can arise when plating with alkaline zinc is an imbalance of brightener in the solution. In this helpful Ask the Expert article, Chad Murphy of Columbia Chemical discusses how different zinc metal concentrations and brightener concentrations can impact efficiency.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreRead Next

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

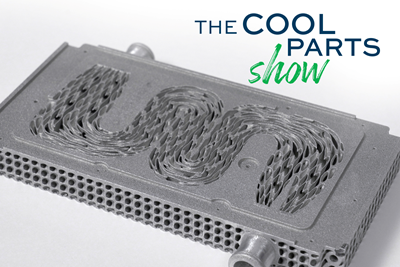

Read More3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read MoreBetter, More Compact Radio Frequency Devices Through 3D Printing

3D printing technology company Fortify is applying its photopolymer process and material developed with Rogers Corporation to serve the expanding RF market.

Read More

.jpg;width=70;height=70;mode=crop)