CFS Expands Electropolishing Services to Additional Markets

After providing electropolishing services to the industrial manufacturing industry for more than 20 years, Custom Fab Solutions has announced it is expanding its offerings to additional markets including food and beverage, medical devices and aerospace.

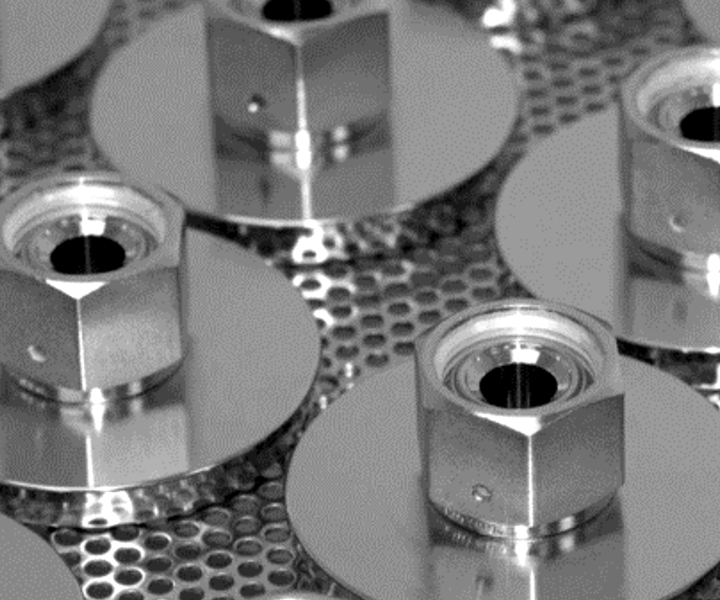

Source | Custom Fab Solutions

Custom Fab Solutions (CFS, Chanhassen, Minn.), a company that has spent the last 20 years providing electropolishing services to the industrial manufacturing industry, has announced it is expanding its offerings to additional markets including food and beverage, medical devices and aerospace. Electropolishing is a critical process that improves the finish and performance of parts and prolongs the part lifecycle – all in one end-to-end procedure. The company is offering a free trial of its electropolishing services to new customers.

“Given the successes and lessons learned, our new customers will see an offering that has been internally honed for years,” says CFS president Kent Herbst.

Doug Brown, Production Manager, Gamma Vacuum (Shakopee, Minn.), says CFS is a key partner for his business. “We’ve partnered with CFS for over 20 years to refine our stainless steel electropolishing and cleaning processes for improved quality, service and cost that makes a difference to daily operations, product output and, most importantly, our customers,” he says.

Related Content

-

Finishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

-

Top Shop Builds Original Systems for Coating Medical Devices

Engineers at Surgical Coatings in Colorado have been ingeniously developing their own equipment, automation, processes and software since this powder coater’s inception in 1995.

-

Precision Coating Receives ISO 14001 Certification

The company says its commitment to the environment and its health led it to seek this certification.