CHEMEON eTCP Touch-Up Pen Qualifies for MIL-SPEC

The DoD qualified products list (QPL/QPD) now includes CHEMEON eTCP Touch-Up Pen.

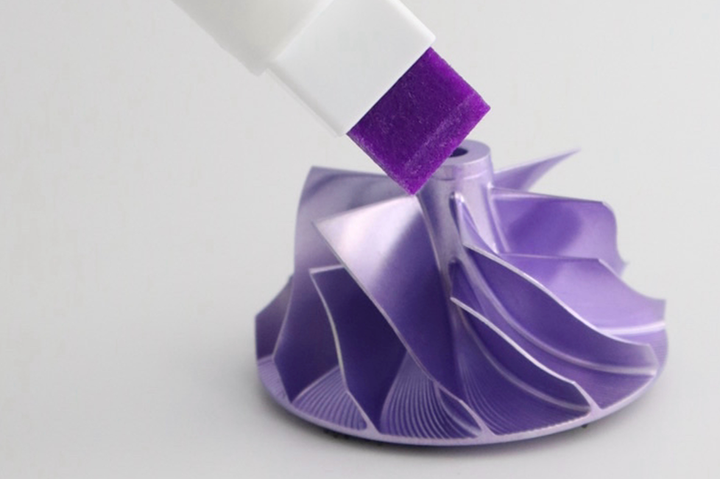

Photo Credit: Chemeon

CHEMEON Surface Technology’s line of QPL approved Touch-Up Pen solutions now includes the patented CHEMEON eTCP Touch-Up Pen. It provides MIL-SPEC corrosion protection and superior adhesion for touch-up, field use, and repair of light metals such as 2024 aluminum. CHEMEON eTCP is the only MIL-DTL replacement of the carcinogenic hexavalent chrome (CrVI, Cr6+) that includes visual verification that your parts are coated and protected.

CHEMEON eTCP Touch-Up Pen provides MIL-SPEC corrosion protection and superior adhesion for touch-up, field use, and repair of light metals such as 2024 aluminum.

CHEMEON eTCP is available internationally and via the corresponding National Stock Number (NSN) for use on all aluminum alloys and other light metals. CHEMEON's eTCP suite of chemistries are REACH, RoHS, WEEE, and SVHC compliant.

For use on bare metal, or as a primer with excellent paint adhesion and corrosion resistance, the patented CHEMEON eTCP Touch-Up Pen conversion coating has completed formal evaluation by Naval Air Warfare Center Aircraft Division. It meets the qualification requirements for MIL-DTL-81706B and MIL-DTL 5541F Type II, Form VI, Class 1A and Class 3 Method D, and as a seal for anodized aluminum.

The safe, easy-to-use pen applicator is considered an essential part of field kits for the DoD and industry. For use on small, intricate part touch-ups to large sea, land, and air vehicle repair, the CHEMEON eTCP Touch-Up Pen reduces human contact with chemicals, retains electrical conductivity, and dries in place.

Dr. Madylon Meiling, CEO of CHEMEON stated, “CHEMEON eTCP Touch-Up Pen MIL-SPEC qualification, and its addition to the Qualified Products List (QPL), demonstrates our company's commitment to creating innovative technology that provides savings, safety, and achieves the asset sustainability goals of global aerospace, military, OEMs, prime contractors, and commercial metal finishers.”

The Power of Protection You Can See is now a reality with CHEMEON eTCP Touch-Up Pen, RTU (Ready to Use) liquid, and Powder, which provide a violet/blue hue to bare metal. This quality control feature was previously unavailable in any MIL-DTL trivalent chrome chemistry and differentiates CHEMEON eTCP from the yellow/gold hue associated to the known carcinogen hexavalent chrome. [Hex Chrome is also known as sodium dichromate, trichrome, or dilute chrome, and is mandated for removal and replacement by the US Government and the EU.]

In 2020 CHEMEON was granted U.S. Patent Number 10.533.254 for the eTCP technology. In addition to its visibility, eTCP has also been demonstrated to provide corrosion protection that exceeds that of competitive TCP products.

In describing the industry need for a MIL-SPEC trivalent chrome with a noticeable color indicator, Dr. Sjon Westre, CHEMEON SVP Technology and eTCP co-inventor, said, "We developed the technology as a safe, non-carcinogenic trivalent chromium conversion coating and anodic seal. The corrosion protection of eTCP is quite a bit better than the TCP coatings, and our invention solved the problem of creating a color, while still meeting or exceeding the MIL-SPEC." Westre continues, "There is a substantial quality control problem and waste of resources in re-running batches if you can't tell a coating has been applied. In the past, we've relied on training and spot tests to address this concern, but the lack of color has been a large barrier to implementation."

For corrosion protection that exceeds MIL-SPEC requirements and provides visual verification that parts are coated and protected for Quality Assurance (QA) and Quality Control (QC), contact info@chemeon.com to schedule complimentary parts testing with CHEMEON eTCP Touch Up-Pen. Visit https://chemeon.com/touch-up-pen/

Related Content

Shedding Light on Surface Inspection

State-of-the-art reflector-based lighting system improves luminosity and ergonomics for surface inspection tasks while reducing energy usage.

Read MoreConcrete Reinforced Bars Built to Last

Not all corrosion-resistant materials for infrastructure are created equally. Epoxy-coated steel rebar has advantages that other materials used to prevent corrosion do not.

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MoreRobots, AI and Superb BMW Surfaces

There isn’t an automotive paint shop in the world that doesn’t have post-paint inspection and defect processing. But BMW is doing this with levels of technology at a plant in Germany that exceed all other paint shops in the world.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)