Custom BUMAX Screws Hold Together World’s Largest Telescope

Fastener manufacturer BUMAX to supply thousands of high-strength and corrosion resistant fasteners for the Extremely Large Telescope, presently under construction.

BUMAX 109 Fasteners

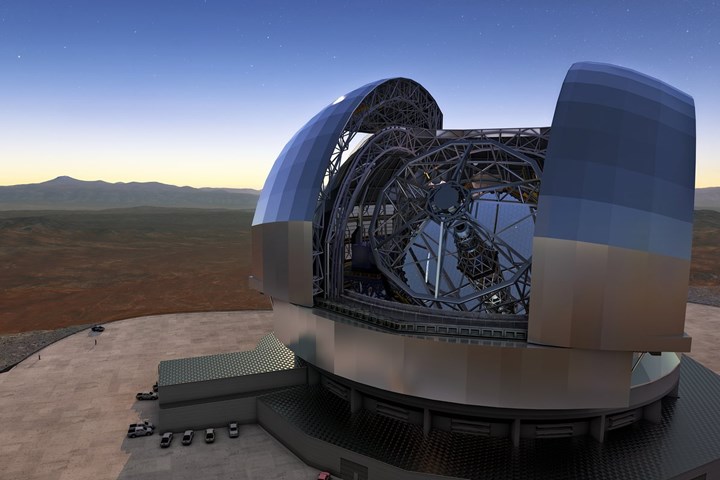

BUMAX (Åshammar, Sweden), specialist manufacturer of stainless steel fasteners, will supply thousands of corrosion-resistant fasteners for the Extremely Large telescope (ELT). The ELT will be the world’s largest telescope when it goes into operation in 2024 in northern Chile. The ELT is currently under construction by Dutch company VDL ETG Projects, who has ordered over 11,000 BUMAX 109 fasteners. The bolts are a customized product that required special tools to manufacture. They have also been coated with Dicronite, a lubricant used to reduce friction. Dicronite is a common surface treatment for fasteners used in telescopes.

“Standard stainless steel bolts lack the strength required for the ELT,” said Michael Evers, project manager at VDL ETG. “We required a 10.9 strength bolt, and with the corrosion resistance of stainless steel. BUMAX offered us the perfect solution. The high-strength BUMAX 109 fasteners prevent damage to the mirror segments, which is very costly. Their corrosion resistance is also essential, as the fasteners are sometimes open to the elements and will reduce future maintenance requirements.”

The ELT is a reflector telescope, collecting universal light using a massive curved mirror that is 39 meters across, three times the area as the world’s second largest telescope. Such a giant mirror is too large to be made from a single piece of glass, so it will consist of 798 individual hexagonal segments, each measuring 1.4 meters across and driven by electrical motors for fine tuning. The segments will work together as a single huge mirror to collect 100 million times more light than the human eye.

The Extra Large Telescope

BUMAX fasteners are used to fix the nearly 800 telescope mirrors to all the segment supports. Twelve pieces of 10-mm long BUMAX 109 M6 bolts per segment are used for more than 900 segments in total (the 798 support segments, plus an additional 133 segments for a continuous swapping process that allows the mirrors to be cleaned and coated while the ELT stays operational). BUMAX has also supplied fasteners for the CERN accelerator in Switzerland, satellites, submarines and more.

.JPG;width=70;height=70;mode=crop)