ProPlate Uses Pure Platinum and Gold in Additive Plating Process

The company says pure gold and platinum are superior at conducting electricity and have other performance advantages compared to platinum-iridium alloys and stainless steel.

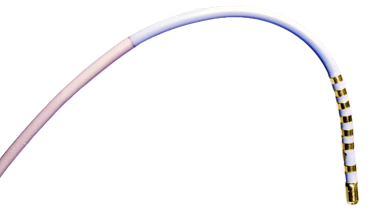

ProPlate (Anoka, Minnesota) uses pure platinum or gold with its additive plating process, rather than using a machining process and various methods of limited installation for rigid stainless steel or platinum-iridium alloys as markers and electrodes. In this scenario, the company says electroplating has a clear advantage. Instead of subtractive machining followed by an installation process such as swaging or crimping, electroplating builds the platinum or gold layer gradually, several micro-inches at a time, and can be selectively applied in myriad shapes and thickness designs with tight control of tolerances. Therefore, ProPlate says it is advantageous in this specific application to use an electrode installation because it enables the use of pure soft forms of metal instead of hard platinum-iridium alloys.

Compared to platinum-iridium alloys and stainless steel, pure gold and platinum are superior at conducting electricity and have other performance advantages. The advantage of gold or platinum is that pure gold shares similar properties and characteristics with pure platinum regarding biocompatibility, low potentials for corrosivity and dissolution, high density, ductility and malleability. Gold is a superior electrical and thermal conductor, while platinum has higher electrical resistivity and hardness properties in comparison. These properties are often advantageous for catheter component performance, especially for applications requiring electrodes for sensing, stimulation and ablation. ProPlate uses electroplating processes to apply gold or platinum onto complex catheter component geometries, often resulting in lower-dimensional profiles and eliminating the risk of marker or electrode ring dislodgement. According to ProPlate, gold electrodes and pure platinum electrodes may result in a higher ablation success rate and reduce char/coagulation formation incidents, making these electrodeposited metals the preferred electrode material of choice over platinum-iridium electrode or stainless-steel materials used in ablation applications.

Related Content

-

NASF/AESF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications – 4th and 5th Quarter Report

The NASF-AESF Foundation Research Board selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. During the reporting period, efforts were focused on planning the overall project work, with the eventual goal of manufacturing an improved design for a Solid oxide fuel cell anode supported flat tube (SOFC).

-

NASF Foundation Research Project #123: Electrochemical Manufacturing for Energy Applications - 10th Quarterly Report

The NASF-AESF Foundation Research Board selected a project on electrodeposition toward developing low-cost and scalable manufacturing processes for hydrogen fuel cells and electrolysis cells for clean transportation and distributed power applications. In this period, we followed our work on 3D printing anode support for solid oxide fuel cells, focusing on the thermal shock properties of 3D printed yttria-stabilized zirconia (YSZ).

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

.jpg;maxWidth=300;quality=90)