American Plating Power Releases LYNQ Software Package

American Plating Power offers the LYNQ software package, a Windows-based desktop solution designed to operate up to 30 rectifiers of a variety of makes and models.

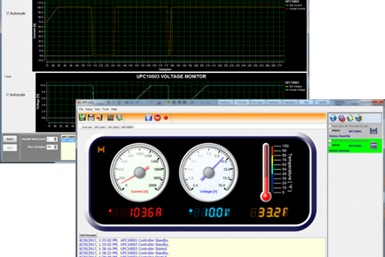

APP LYNQ Software

American Plating Power released the LYNQ software package. This desktop solution is a Windows-based software designed to operate up to 30 rectifiers of various makes and models. Some of the features include voltage/current control, remote monitoring, data storage, a bath temperature display, a real-time messaging board, a profile generator, fault indication and many more.

The software and license allows for the control and monitoring of each individual rectifier through one of American Plating Power’s process controllers. This allows the user to operate each rectifier remotely from the APP LYNQ Software or locally from the controls, such as a UPC 5000E Process Controller or APC 50E Touchscreen Controller, and still have the ability to monitor, trend and log their status. Each type of SCR or Switchmode rectifier can interface with any of the controllers offered by American Plating Power.

American Plating Power and its partners offer over 50 years of global knowledge and development experience to the evolving field of industrial power supplies. This includes DC, AC and Periodic Pulse Reverse Rectifiers as well as related equipment for industrial use globally. The sales team at American Plating Power brings more than 110 combined years of experience in the sale of power conversion products into Industrial applications.

Related Content

-

A Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

-

Liquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

-

Troubleshooting Alkaline Zinc

One of the most common problems that can arise when plating with alkaline zinc is an imbalance of brightener in the solution. In this helpful Ask the Expert article, Chad Murphy of Columbia Chemical discusses how different zinc metal concentrations and brightener concentrations can impact efficiency.

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)