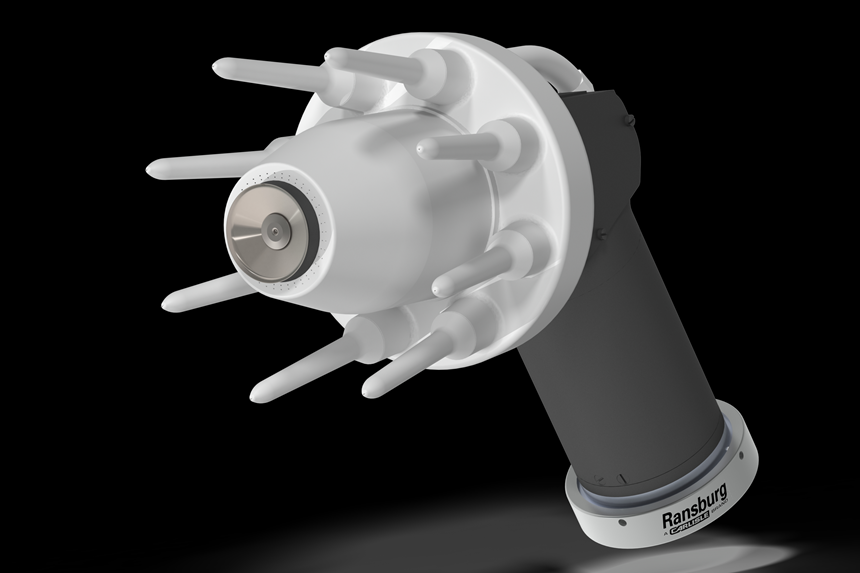

Carlisle Fluid Technologies Introduces New Rotary Atomizer Series

The RMA-600 Series of robot-mounted rotary atomizers increases transfer efficiency, delivers improved spray pattern control, improves cleanliness during operation and provides longer lasting components.

Carlisle Fluid Technologies (Toledo, Ohio) introduces the new RMA Series Rotary Atomizers. The RMA-600 Series is Ransburg’s next generation of robot-mounted rotary atomizers focused on increasing transfer efficiency, delivering improved spray pattern control, improving cleanliness during operation and providing longer lasting components. The 600 series of applicators can reportedly be used across a wide range of solvent and waterborne materials. The applicators have the capability to operate with or without electrostatics using direct and indirect change technology, which the company says makes the 600 Series a versatile applicator.

The RMA 600 Series offers a full range of applicators including the RMA-660 Direct Charge Solvent, RMA-670 Indirect Charge Waterborne and the versatile RMA-680 Direct Charge Applicator that can spray solvent or waterborne materials. “Our engineering team designed an applicator that offers improved production uptime and more robust components,” states Justin Hooper, Carlisle Fluid Technologies global product manager, automatic atomization. “This was achieved with a long life turbine, single-piece splash plate design and quick-connect tubing bundle to mention a few key features. All this while increasing transfer efficiency.”

Related Content

-

Masking Solutions Provider CFS Dramatically Expands Capabilities and Capacity

Custom Fabrication & Supplies (CFS) completed a new plant expansion packing 10 times the capacity into twice the space. It dramatically enhances the supplier’s custom capabilities to provide extremely precise and cost-effective masking solutions.

-

The Value of Robotic Paint Performance Testing

Considerations for implementing the use of automation for paint performance testing.

-

Coatings Plant Evolves with Market Trends

Expanding its focus from exclusively serving the RV industry, one of this company’s stand-alone coatings plant has successfully extended its services to additional markets.