Dürr Introduces Quick-Change Rotary Atomizer

The EcoBell4 atomizer features new four-main-needle technology, which reportedly needs only four seconds per color change for high-runner paints.

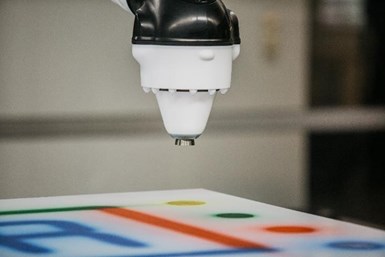

The newest atomizer generation from Dürr (Southfield, Mich.), the EcoBell4, is said to perform color changes faster than any other high-speed rotary atomizer. It is designed to reduce paint and solvent consumption and volatile organic compound (VOC) emissions, and it also features radio frequency identification (RFID) technology for predictive maintenance. Dürr is offering two variations in the same atomizer generation: the basic version for standard applications and the pro version for special processes like 4x1C or 3x2C.

The pro version of the EcoBell4, featuring the new four-main-needle technology, reportedly needs only four seconds per color change for high-runner paints. The significantly shorter color changes positively impact paint and solvent losses, which are said to be lower than any other atomizer on the market.

The EcoBell4 Pro can be used for interior and exterior painting in addition to all paint materials. The portfolio includes atomizers for both water-based and solvent-based paints. The EcoBell4 Pro can serve both existing and new painting needs, from 4x1C painting for the base coat to 3x2C solutions for clear coat and all combinations in between.

According to Dürr, the flexibility of the EcoBell4 Pro is best demonstrated in combination with the new EcoProBooth. With its smart painting booth design, the EcoProBooth combines all painting tasks into one box, including the new EcoBell4 Pro Ux atomizer. The same bell disk/shaping air ring and external charge system handle all interior, exterior and metallic painting (bell-bell process). The atomizer equally applies narrow spray jets inside the body and wide spray jets on the outer skin. Another innovation is the patented exchangeable external charge systems, which individually combine within the Pro series. Dirty electrode rings are discarded and replaced with clean ones in one of the four service cubicles of the EcoProBooth without stopping the system for cleaning to take place.

All EcoBell4 atomizers are equipped with RFID technology. In addition, Dürr has enhanced the external charge system to increase efficiency. Other new features include a robust rotation speed acquisition system designed for easier maintenance, a vibration sensor integrated into the robot that detects imbalances in the bell disk and turbine before they cause damage and a protective stocking with a patented attachment concept. This feature is said to reduce soiling so that at least four hours of painting are possible without cleaning the atomizer in between.