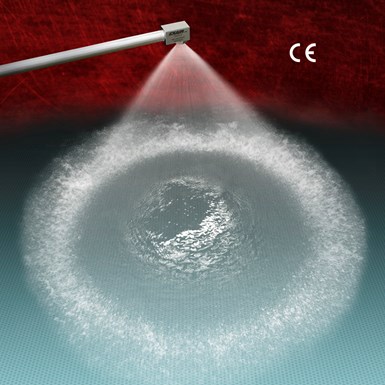

Hollow Cone Liquid Nozzle Provides up to 250 PSI Operating Pressure

The 1/2 NPT HollowStream liquid nozzle from Exair performs a variety of applications across the industry with a hollow cone spray pattern.

Photo Credit: Exair

Exair’s 1/2 NPT HollowStream liquid atomizing spray nozzle provides a hollow cone spray pattern for pressurized liquids. Nozzles of this variety are applied to solve many problems, including cooling, cleaning, rinsing and dust suppression applications for the industry. The tangential flow design is vaneless. Its wide, open internal features are designed to resist clogging and work well with liquids containing particulate. These liquid nozzles produce a uniform distribution of liquid in a ring pattern with medium to large droplets. Their right angle design is compact and can fit in small areas, Exair says. The liquid nozzles’ liquid operating pressure is up to 250 psi.

With HollowStream nozzles, the liquid is supplied into the body of the nozzle, creating a swirling action within a vortex chamber. This vortex produces the hollow-cone spray pattern when the precision nozzle breaks the liquid surface tension as it exits the orifice and into a controlled spray angle. With an adjustable flow rate, it’s perfect for dust mitigation, pollution scrubbers, foam breaking and more.

The type 303 stainless steel construction of liquid atomizing nozzles is said to add to their durability and corrosion resistance. HollowStream nozzles are CE compliant and available in a variety of flow rates. They complement Exair’s large line of other 1/8, 1/4, 3/8 and 1/2 NPT liquid nozzles, which are also available in a variety of liquid patterns and flow rates.

Exair | 800-903-9247 | exair.com

Related Content

-

From Drain to Gain with Smart Wastewater Recovery

Incorporating digital monitoring to maximize performance.

-

Pretreatment of Black Oxide

Having issues achieving a consistent color with the application of black oxide? Start by looking at your pretreatment. Connor Callais of Hubbard-Hall offers advice for troubleshooting your black oxide process.

-

Alkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.