SIFCO ASC Refines Titanium Plating Process Using Automation

Existing titanium plating techniques tend to be highly corrosive, potentially poisonous or short-lived in their effectiveness, according to SIFCO ASC. The company undertook extensive experiments with two widely used titanium alloys to find a more efficient plating process.

SIFCO ASC has developed a bespoke range of automated solutions for the plating of titanium. The proprietary process is said to give customers a consistent, repeatable means of enhancing titanium alloys for use in mission-critical components.

The new process is said to overcome a key challenge in the use of titanium for certain applications. According to SIFCO ASC, titanium’s poor resistance to abrasive or adhesive wear makes it unsuitable for use as, for example, aircraft landing gears and automotive internal combustion engines. Plating the titanium enhances its performance characteristics, including improved lubricity, corrosion resistance and conductivity, as well as heat reflection and emissivity. Despite this, titanium is said to be notoriously difficult to plate, largely because of an oxide film that forms the moment it becomes exposed to oxygen.

Existing titanium plating techniques tend to be highly corrosive, potentially poisonous or short-lived in their effectiveness, according to the company. SIFCO ASC undertook extensive experiments with TI 6-Al 4-V and TI 6-6-2, two widely used titanium alloys, to find a more efficient plating process.

The resulting process includes surface pre-treatments of mechanical finishing, followed by an etch and activation, as well as the introduction of a thin layer of nickel. SIFCO ASC says this approach brings all the benefits of selective plating – including versatility and convenience – together with enhanced safety and component quality.

To avoid oxidization – and therefore costly scrappage of compromised titanium – the electrolyte solution must flow continuously over the component at all times. This problem could be eliminated through automation. Derek Kilgore, engineering manager at SIFCO ASC, explains, “[Automated systems] not only reduce human error, but also introduce vital benefits in terms of quality, repeatability and traceability or data logging, as well as productivity and user safety.”

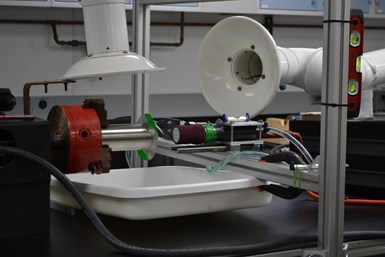

The automated system designed by SIFCO ASC uses a portable TechnoPlate — a programmable power pack which enables repairs to be plated in situ and also stores the volts, amperage and ampere hours, eliminating the risk of human error and oxidization.

Additionally, for non-titanium applications, SIFCO ASC can design, specify, deliver and commission simple workbenches or fully automated workstations with robotic systems to handle components, anodes and solutions through radio-frequency identification (RFID) and barcode tagging. According to the company, the only human intervention necessary is programming and replenishing solutions.

Related Content

-

Nanotechnology Start-up Develops Gold Plating Replacement

Ag-Nano System LLC introduces a new method of electroplating based on golden silver nanoparticles aimed at replacing gold plating used in electrical circuits.

-

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.