Spatial Coating Thickness Measurement Solution for Prismatic Battery Cells

Coatmaster AG’s 3D noncontact coating thickness measurement system employs ATO technology to provide spatial measurement of coating thickness.

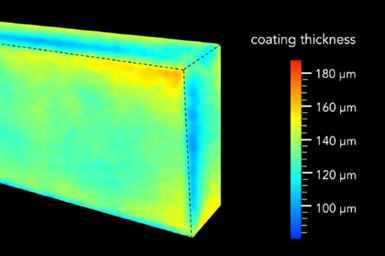

Coating thickness distribution on battery cell with noncontact coating thickness measurement technology. Photo Credit: Coatmaster AG

Responding to the need for better insulating coatings on prismatic battery cells, Coatmaster AG has developed the Coatmaster 3D noncontact coating thickness measurement system. The tool employs advanced ATO technology to provide spatial measurement of coating thickness across all side faces and edges inline within a split second, confirming uniform thickness throughout the cell.

The manufacturing of prismatic battery cells, which are indispensable to the e-mobility industry, involves a specific cuboid geometry. A key component of these cells is an insulating coating, the minimum thickness of which is crucial for maintaining electrical isolation. However, industry-wide issues have plagued the accurate measurement and assurance of minimal thickness, especially at the cell edges. These issues are compounded by varying factors, such as viscosity, surface tension, curing behavior, edge curvature and the spatial spray pattern of the coating gun.

Past approaches attempted to measure the coating thickness on the cell’s side faces, anticipating a correlation between these values and those at the edges. However, recent studies show only a weak correlation due to the above variables. Additionally, the position of the minimum thickness along the edges is not constant, necessitating a spatial approach to measuring coating thickness. Aware of this, battery manufacturers carry out additional visual control of the edges, which generates additional costs and resources.

“Coatmaster 3D is a major leap forward in the prismatic battery cell production landscape,” says Andor Bariska, co-CEO of Coatmaster AG. “Not only does it enhance efficiency and quality control but it also significantly improves the safety and reliability of e-mobility solutions.”

Multiple initiatives are in progress to substitute the previous, inadequate measurement technologies with the Coatmaster 3D solution. In a short period, Coatmaster 3D has emerged as the new industry standard, the company says. Through its technology and approach, Coatmaster AG says it aims to usher in a new era of prismatic battery cell manufacturing, underscoring its commitment to advancing the industry standards.

Related Content

-

Multi-Functional Coating Test Instruments Operate Like “Swiss Army Knives”

With greater flexibility than limited traditional equipment, modern analytical instruments can ensure reliable coating performance by measuring critical characteristics like friction, peel, wear, and scratch resistance.

-

Corrosion Resistance Testing for Powder Coating

Salt spray can be useful to help compare different pretreatment methods and coatings but it does not tell us much about the corrosion resistance of a part over time in the field. Powder coating expert Rodger Talbert offers insights into how to get a better idea of how to improve a part’s corrosion resistance in the real world.

-

Attention to Measurement

English vs. Metric — which should you use? Ron Kinne of Haviland Enterprises Inc. explains why you need a firm understanding of both for measuring various aspects of plating processes.

.jpg;maxWidth=300;quality=90)