Variable Frequency Drives Deliver Intelligent Control of Conveyor Systems

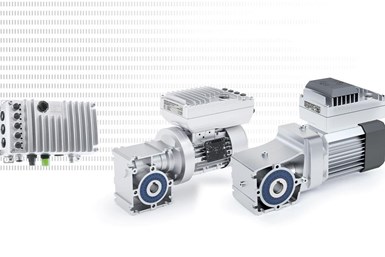

Source: Nordac Nordac ON/ON+ variable frequency drives (VFDs) deliver intelligent control of conveyor systems with an integrated multi-protocol Ethernet interface to improve efficiency, reduce system variants and optimize performance, the company says.

Nordac ON/ON+ variable frequency drives (VFDs) deliver intelligent control of conveyor systems with an integrated multi-protocol Ethernet interface to improve efficiency, reduce system variants and optimize performance, the company says.

These VFDs are available in three frame sizes for scalable functionality. They have been engineered for the specific requirements of horizontal conveyor technology and feature integrated functions to optimize operation performance, an integrated Ethernet interface, full plug-and-play capability, and a compact design.

They feature two base versions: a version designed for combination with IE3 asynchronous motors (NORDAC ON) and a version optimized for use with IE5+ synchronous motors (NORDAC ON+). Both versions offer compact frame sizes that can be motor- or wall-mounted based on the application and space requirements. The drives can be used over a speed range, enabling variant reduction for large intralogistics systems and streamlining operation.

Nordac ON supports a power range of 0.50 – 3.00 hp while ON+ supports 0.50 – 4.00 hp. As with all NORD variable frequency drives, the ON/ON+ is equipped with a dynamic internal PLC for drive related functions. It can process data from connected sensors and actuators, initiate control sequences, and communicate drive and application data to the control center, networked components or to cloud storage. For this purpose, the VFDs have an integrated multi-protocol Ethernet interface for easy integration into automation systems. Whether for ProfiNet, EtherCAT, or EtherNet/IP, the required protocol can be easily set via drive parameters. Firmware updates can also be implemented via Ethernet.

In addition to simple configuration, ON/ON+ VFDs offer quick installation and maintenance with full plug-and-play functionality. The 24 V DC supply for control and communication is integrated into the three-phase 400 V supply connected to the drive via a six-pole connector. A daisy chain connector can also be used to supply power to multiple drives, optimizing cable lengths and significantly reduce wiring efforts.

ON/ON+ VFDs include a variety of integrated functions to improve conveyor efficiency and integrate seamlessly with Industrial Internet of Things (IIoT) environments. These functions include integrated sensors via digital inputs, LED indicators for quick and simple diagnostics, an energy-saving function for optimized efficiency in partial load operation, and brake management for precise control of an electromagnetic holding brake for wear-free brake actuation. Optional functions such as Safe Torque Off (STO), Safe Stop (SS1-t), and internal braking resistors are also available for configuration.

With their scalable functionality and dynamic control, ON/ON+ variable frequency drives are suitable for a range of environments, particularly those in warehousing, post and parcel, airport technology, and other large-scale intralogistics applications.