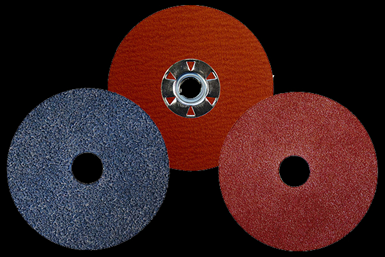

Weiler Program Helps Manage Abrasive Costs, Improve Productivity

The Weiler Consumable Productivity (WCP) program is designed to help end-users better manage their abrasives costs and increase productivity.

The Weiler Consumable Productivity (WCP) program is designed to help end-users better manage their abrasives costs and increase productivity. WCP tests and evaluates abrasives to compare product life, reduce cycle times and increase efficiencies.

The program involves time studies and observation of abrasive usage to gather quantitative data that can be measured and verified, leading to a repeatable solution. Weiler representatives look at how abrasives are used, how long they last and how productive they are.

By comparing several products throughout the process, Weiler provides a recommendation for the best, most productive abrasive for the application.

“The WCP program can bring real value to end-users, especially if they are experiencing bottlenecks in their operations, have short abrasive life and want to improve performance,” says Ron McCarthy, abrasives specialist, Weiler Abrasives. “Our goal is to set them on a path of cost savings and better productivity — and we’re confident we can do that.”

Weiler Abrasives |800-835-9999 | www.weilerabrasives.com

Related Content

-

Practical Environmental Management Reduces Costs, Refines Quality

By focusing on effluent treatment and efficient tin recovery, this Indian surface treatment plant meets stringent environmental standards and sustainable high-quality production.

-

Finishing Another Year — Looking Back at the Trends of 2023

Products Finishing reflects on a year of reporting on the surface finishing industry and looks ahead to what may be in store for 2024.

-

Beware the Employee Freeloader

Clearly communicate expectations, set goals, measure performance and trust your instincts.