3 Reasons to Implement Vacuum Degreasing

Improvements in air emissions and waste when using vacuum degreasing also result in cost reduction.

Q: Why should I invest in a vacuum degreaser for solvent cleaning?

A. A vacuum degreaser, also known as an airtight/airless degreaser, has three main benefits in terms of cost savings, process security and environmental protection:

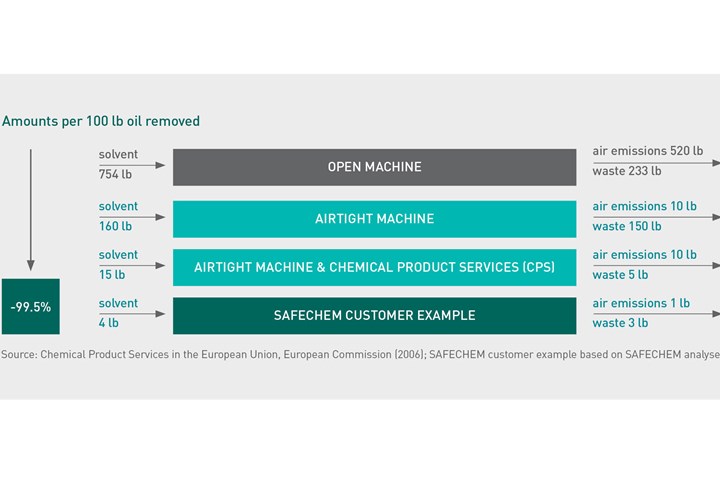

- Cost efficiency. In an open-top degreaser, most of the solvent is not used for the cleaning process itself. Instead, it is evaporating into the atmosphere, which is both a cost and environmental problem. Figure 1 shows the amount of solvent required to remove 100 Ibs of oil and the corresponding losses because of air emissions and solvent that ends up in waste streams when different machine technology is applied.

In airtight/airless machines, used solvent can be constantly re-purified and almost completely recycled in the distillation unit. This routine recycling means there are very low solvent replacement volumes necessary. Thanks to efficient recycling with vacuum distillation, solvent in the waste stream is minimized. Less than 10% solvent in waste is typical compared to 50% or more in average open-top systems.

For example, one Safechem customer that has implemented an airtight degreaser now requires 99.5% less solvent consumption than it did with its previous open-top cleaning equipment.

Vacuum degreasers can further expand solvent life by the addition of stabilizers, which results in less solvent consumption and fewer bath exchanges. In an open-top system, frequent disposal of solvent as waste as well as replacement is much more costly than the use of stabilizers.

Also, in a vacuum degreaser, the working chamber only opens following vacuum drying, so there are no solvent residues left on parts and no drag-out losses.

- Process security. You can easily monitor the condition of your solvent on site using simple test kits. Usually, testing takes no more than 20 minutes a week, and the results will tell you whether re-stabilization is necessary. The addition of stabilizer concentrates not only helps counteract the evolving acidity but also prevents discoloration or metal catalytic effects while enabling safe pH value and reliable processes.

Because of distillation, vacuum degreasers use clean solvent to achieve consistent and repeatable results. While the high solvent quality in the rinsing step already enables a required level of cleanliness, this is followed by

Fig. 1.The chart shows the amount of solvent required to remove 100 Ibs of oil and the corresponding losses that are due to air emissions and solvent that ends up in waste streams when different machine technology is applied. Photo Credits: Safechem

vapor degreasing as the last cleaning step. This process is highly effective given the temperature difference between parts and vapor.

Furthermore, vacuum drying minimizes the risk of solvent being trapped in blind holes and small crevices even when rotation is not used.

- Environmental protection. There are virtually no air emissions in an airtight/airless machine which is a cost, environmental and worker safety benefit. Hermetically sealed construction means there is minimal risk of contaminating ground water compared to open-top systems.

Vacuum degreasers can be fully automated with handling systems and robotics removing operator handling so operators have virtually no contact with the chemical. The safety aspect can be further enhanced by closed loop safety containers to enable emission-free and spill-free transfer of solvent to/from the cleaning machine.

Both halogenated solvents and non-halogenated solvents, such as modified alcohols, can run in airtight/airless degreasers.

Given that new stringent regulations are coming for many traditional solvents such as perchloroethylene and trichloroethylene following the EPA’s risk assessment, modified alcohols — which are chlorine-free, bromine-free and fluorine-free — have no environmental legislation concerns and represent a viable cleaning solution. Also, they are much more cost-effective than fluorinated products, which run on open systems and are similarly subject to increasing global regulatory pressure.

The capability of modified alcohols to process both polar and non-polar contaminations may also reduce the need for additional cleaning processes and help save costs.

The advanced technology of vacuum degreasers requires very low maintenance. Equipment manufacturers are also able to customize machines capable of processing large parts such as aerospace structures, nacelles, meter-long tubes, and so on. Particularly for companies who need to meet a high-volume throughput of cleaned and dry parts, airtight/airless degreasers can deliver exceptional results.

About the Author

Chris Tivnan

Chris Tivnan is sales manager North America at Safechem North America Inc. Contact:

c.tivnan@safechem.com

Related Content

3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreCorrosion Resistance Testing for Powder Coating

Salt spray can be useful to help compare different pretreatment methods and coatings but it does not tell us much about the corrosion resistance of a part over time in the field. Powder coating expert Rodger Talbert offers insights into how to get a better idea of how to improve a part’s corrosion resistance in the real world.

Read MoreHow to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreUnderstanding and Managing White Spots on Anodized Aluminum

Having trouble with spotting defects when anodizing? Taj Patel of Techevon LLC offers a helpful overview of the various causes of white spots and potential solutions.

Read MoreRead Next

Replacing Open-Top Vapor Degreasing in Aerospace Manufacturing

Options and considerations for cleaning aerospace parts as regulations tighten on vapor degreasing solvents.

Read MoreThe Right Solvent Creates the Cleanest Parts

Cox Manufacturing Co. has worked with Kyzen Corp. since it implemented its vacuum vapor degreaser to find just the right chemical solvent to clean its customers’ parts to their specifications and beyond.

Read MoreAqueous or solvent-based cleaning?

Considerations for choosing the right cleaning solution.

Read More