For Tawas Plating Company & Tawas Powder Coating Inc., automation electroless nickel baths have improved consistency in the plating deposit finish and higher overall product quality.

Photo Credit: TPC

Since its “rediscovery” in 1946 by Abner Brenner and Grace E. Riddell (1), electroless nickel (ENi) has become widely used globally in a multitude of manufacturing applications. Its many features and benefits such as corrosion and wear resistance, uniform coverage even on complex items, tight control of deposit thickness and no post-machining have gained acceptance in a wide range of manufacturing applications. In the past several years, there has been a resurgence in its use in domestic manufacturing not only in more specialized fields such as aerospace, aeronautic and avionic technology, medical equipment and the military, but also in general manufacturing such as the automotive industry. Since domestic plating facilities are generally smaller than those overseas, increased automation of the overall plating process is key to competing at the international level (2).

The Opportunity

Tawas Plating Company & Tawas Powder Coating Inc. (TPC) in Northeast Michigan, provides world-class finishing services to the automotive, heavy truck, medical, oil and gas and other manufacturing industries. A large part of the company’s business is offering low phosphorus, mid phosphorus, and high phosphorus ENi plating options with seven operating baths.

WNI600 Series Electroless Nickel controller manufactured by Walchem – IWAKI America Inc.

Photo Credit: IWAKI America Inc.

“Because of the labor expense and operator variability in the titration testing used for ENi bath control, we made the decision to investigate available nickel controllers in the market,” says Michael Moore, Lean Champion at TPC.

This also fit TPC’s ongoing continuous improvement efforts, as the company further identified automating its ENi baths as a key component for providing higher quality goods to meet the increasingly demanding requirements of its customers. TPC also recognized this as an opportunity to improve production rates, improve chemical consumption, reduce waste and free up personnel for more value-added services. After extensively researching options for automating its ENi baths, TPC realized that one of its current equipment suppliers had a viable option in the form of an online spectrophotometric nickel/pH controller. Although these types of controllers have been in the market for nearly 40 years, the latest generation provides exceptional performance, improved reliability, integrated data handling and alarm notification/escalation, LAN connectivity, DCS integration via Modbus TCP and remote accessibility.

“We recognized that automating all of our plating tanks would be a capital-intensive purchase,” says Moore, “but were convinced it fit our long-term goals.”

The Solution

A WNI600 Series Electroless Nickel controller manufactured by Walchem - IWAKI America Inc. (Holliston, Mass.) was installed in a trial run to control two ENi baths both operating a mid-phosphorus ENi application.

Moore notes, “The ability of the WNI600 to control two tanks simultaneously provided us an opportunity to significantly reduce our upfront costs.”

The controller integrates an optoelectronic nickel sensor that measures the absorbance of the bath media that passes through a flow cell of fixed pathlength. A light source passes through the media and a photodiode detector measures the absorbance of light at specific wavelengths which is directly proportional to the nickel concentration. The signal is converted to the nickel concentration and displayed and recorded by the controller. In addition, an online pH sensor is also utilized. When operating in control mode, chemical feed pumps connected to relay outputs maintain the bath chemistry. Nickel concentration is maintained within a desired deadband. A reducing agent, in this case hypophosphite, is fed in proportion to the nickel replenishment chemistry. In addition, a pH modulator is fed to maintain the pH within a desired deadband. Bath age is determined by calculating the metal turnovers (MTOs) and an alarm set to notify operators as they approach the time to switch over the bath. All data is collected and stored locally on the controller as well as maintained using a cloud-based account management software tool, Walchem Fluent, that incorporates IoT, process automation, remote monitoring and control, and data visualization. The controller was also directly tied into TPC’s LAN system for easy access anywhere within the plant.

The Results

“Startup was quick and easy,” Moore says, “we were able to easily navigate through the operator interface and quickly program in specific parameters for our processes within minutes. Once completed, we were off and running.”

To gain the line operators’ confidence in the results, the controller was initially placed in monitoring mode and compared side-by-side to the plant’s laboratory nickel analyses performed via EDTA titration.

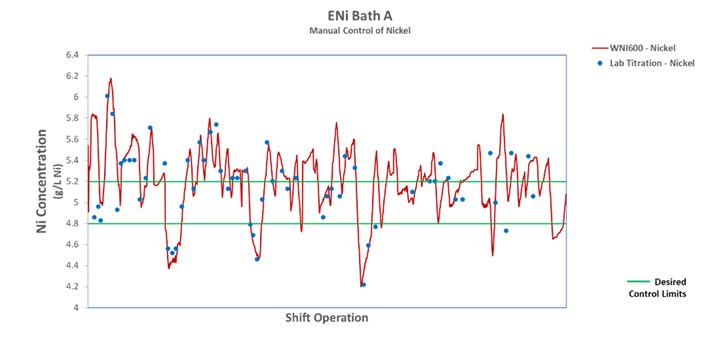

Figures 1 and 2 compare the nickel concentration and pH readings on Bath A from the controller to the laboratory EDTA titration and pH results, respectively. The plant desired to maintain a control range for the bath at 5.0 ± 0.2 g/L nickel. Excellent tracking and correlation between the two were observed with the controller averaging 5.19 g/L with a standard deviation of 0.32 and the EDTA titration results averaging 5.15 g/L with a standard deviation of 0.35.

Figure 1 – ENi Bath A comparing lab titration for nickel versus controller results.

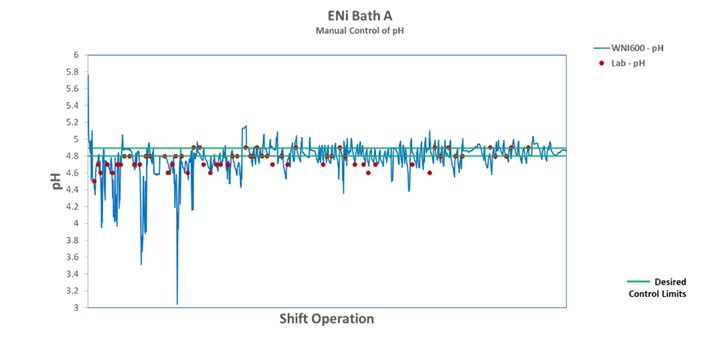

Good correlation of the pH reading from the controller and the line operators was also observed. The desired pH range is 4.9 ± 0.1. The controller recorded an average pH of 4.77 with a standard deviation of 0.19 while the line operator pH readings averaged 4.8 with a standard deviation of 0.1.

Figure 2 - ENi Bath A comparing lab pH versus controller results.

These results satisfied the operation of the controller to plant management and the controller was placed into control mode.

“Originally, our plan was to keep a close eye on the controller results compared to our titrations and pH checks for about one month,” explains Moore. “But after about a week, the results impressed us so much that we decided to let the controller do its thing.”

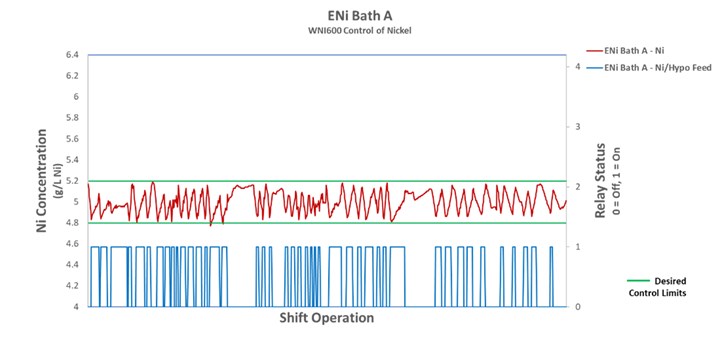

Figure 3 – Nickel results once WNI600 is placed into automatic mode. Activation of nickel replenishment chemistry and hypophosphite feed is also shown.

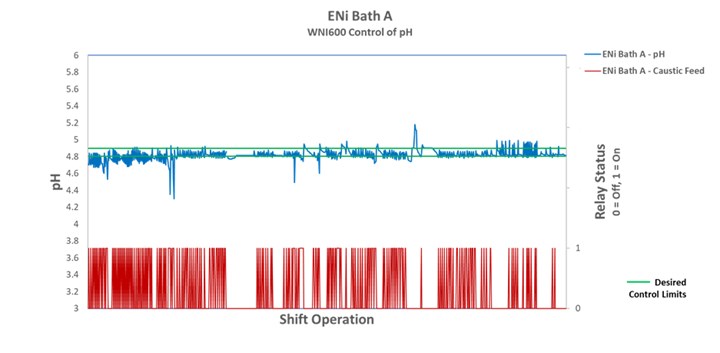

The existing plant chemical feed pumps, bellows style pumps, were utilized and tied into the appropriate relay outputs for chemical feed. A dual bellows pump was set up to feed both the nickel replenishment chemistry and the hypophosphite with the pump output set to proportion the nickel to hypophosphite ratio based on the chemical supplier’s recommendation. A second bellows pump was used to feed caustic for pH control. Figures 3 and 4, show the nickel and pH results once the controller began controlling chemical feed and controlling the pH level, i.e., feeding the nickel replenishment chemistry, hypophosphite, and caustic to the bath. In addition, the graphs show the corresponding times that the chemical feed pumps were activated and deactivated. The bath’s nickel concentration was maintained at 5.00 g/L with a standard deviation of 0.09. This was well within the desired control limits of 4.80 to 5.20 g/L and over 3.5 times improvement over manual control.

Figure 4 - pH results once WNI600 is placed into automatic mode. Activation of caustic feed is also shown.

Similar results were also observed for the pH control. The pH averaged 4.82 with a standard deviation of 0.07. As with the nickel control, this was well within the desired control limits of 4.8 to 5.0 pH units.

The Benefits

“Real time monitoring and automating the control of our nickel baths has provided us with tremendous benefits,” says Kevin Jungquist, President of TPC. “We have gained more robust baths allowing us to operate within a tighter process window. This has made for a more consistent plating deposit finish for our final products. On top of this, the ability to see real-time data and alarm notifications at the controller, at my desk, or even on my phone has allowed us the ability to quickly respond to any process upset at any time and from anywhere.”

He adds, “The final and probably the most important benefit of the switch to the nickel controller has been the overall reduction in time and expense of manual titrations and overall tank maintenance. The operators know exactly how many turns the bath is at any time and when they are approaching the time to turn over the tank. As a result, we have been able to free up resources to perform other important and value-added tasks which have improved our efficiencies.”

Summary

Significant improvement in the overall control of an ENi bath has been demonstrated in a real-world application via the use of an online spectrophotometric nickel/pH controller. The result has been improved consistency in the plating deposit finish and higher overall product quality. This would allow even small- to mid-sized plating operations to better position themselves to meet increasing customer quality requirements and better compete on a global scale.

Automation and control of ENi baths has seen a rise in interest over the past several years. Tighter control of the ENi process aids in attaining the correct final product quality whether it be corrosion resistance, hardness, brightness, etc. It also assures correct nickel to phosphorus content and minimizes the potential for voids, pitting and poor adhesion.

For more information visit https://www.walchem.com/metal-finishing-surface-treatment/ and tawasplating.com

References:

1. Brenner, Abner and Riddell, Grace E., “Nickel Plating by Chemical Reduction,” US Patent 2,532,283 issued December 5, 1950.

2. “Automation and the Finishing Industry – Sharretts Plating Company”, SPC Blog, www.sharrettsplating.com/blog/automation-and-the-finishing-industry

Related Content

How to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreTrivalent Chrome Overview

As the finishing industry begins to move away from the use of hexavalent chromium to trivalent chromium, what factors should finishers consider as they make new investments? Mark Schario, chief technology officer for Columbia Chemical offers a helpful overview of this complicated topic.

Read MoreLiquid Chrome Vs. Chromic Acid Flake

Contemplating how to continue offering chromic acid services in an increasingly stringent regulatory world? Liquid chrome products may be the solution you’re looking for.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreRead Next

Enhancing the Corrosion Resistance of Electroless Nickel with TCP

Ronatec and CHEMEON have achieved promising early results for bolstering electroless nickel corrosion resistance through the application of a trivalent chromium pretreatment (TCP) top coat.

Read MoreHistorical Highlights of Electroless Plating

In a 1984 article in Plating and Surface Finishing, for the AESF 75th anniversary year, Charles R. Shipley Jr. recounts the history of the commercialization of electroless plating beyond the discovery of electroless nickel by Dr. Abner Brenner and Grace Riddell at the National Bureau of Standards.

Read More

.jpg;maxWidth=300;quality=90)