Brush Plating

The benefits of plating localized areas with a portable plating system.

Brush plating, also known as selective plating, is a portable process used to apply localized electroplated deposits and anodized coatings, as well as for electro-polishing. It is used by OEMs to enhance specific areas on production parts, as well as to correct dimensional errors made in machining. It is also used in repair or job-shop applications.

Applications and Benefits

Brush plating is commonly used in a broad range of industries that include aerospace, oil and gas, power generation, marine, defense, and general manufacturing. There are numerous commercial and industry specifications for brush plating and anodizing.

Brush plating’s portability and versatility make it a great finishing tool. It can be mechanized or automated, and used anywhere in the shop or out in the field. It focuses the plating or anodizing onto only those specific areas that require the coating, and can significantly minimize the amount of time spent masking compared with traditional tank-plating processes. Another key benefit is that it uses very small volumes of solutions to accomplish the job at hand.

Brush Plating Basics

A portable power pack (rectifier) provides the direct current required for plating, anodizing and electropolishing. The power pack has two leads, one of which is connected to the plating tool and the other which is connected to the part being finished. The direct current supplied by the power pack is used in a circuit that’s completed when the plating tool is touching the work surface. A brush-plating power pack gives the operator the ability to control and monitor the voltage, amperage and ampere hours for a given job, as well as to change the polarity as required for each of the steps involved in the process.

In a typical operation, the part is first masked and then a series of base material-specific preparatory steps are conducted to ensure an adherent deposit. The last step is the plating of the metal deposit to the desired thickness.

Brush plating requires movement between the plating tool and the part. This can be accomplished by moving the plating tool over the part, by moving the part and keeping the plating tool stationery, or by moving both. Dedicated electrodes are used for each operation in the process to electrochemically prepare the part and then to plate the final deposit. The electrodes are covered with an absorbent material saturated with a solution and then applied to the part.

Brush-Plated Deposits

Brush-plated deposits are applied at much faster rates than those achieved in tank plating. With proper surface preparation, the quality of the deposit and adhesion is equivalent or superior to good tank plating practice, typically in excess of 11,000 psi. Most brush plating deposits have a dense, non-porous and uniform crystalline structure.

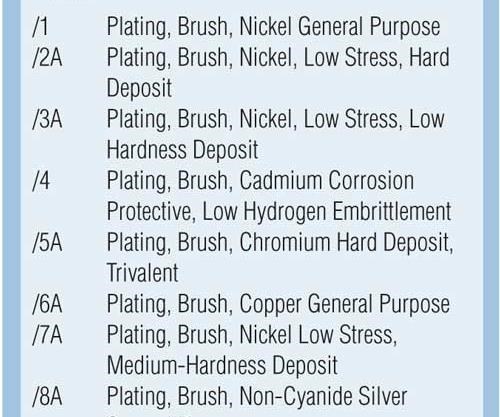

The manufacturers of brush-plating equipment generally offer a number of plating solutions for each of the more important metals. One reason for this is to offer a choice in properties. For example, one application may want a hard, wear-resistant nickel, while another needs an impact-resistant, ductile coating. Since the ductility of metals generally decreases with increasing hardness, it is impossible to meet both requirements with a single solution. New to the brush-plating industry are highly specialized metal-matrix composite coatings such as cobalt chromium carbide (CoCr3C2) deposit.

When to Brush Plate?

Brush plating should be considered:

- When you need an accurately controlled thickness on a localized area of a part.

- When tank electroplating is not an option (e.g., the part is too large for the tank, masking for tank plating is too complex, or the plater’s lead time isn’t acceptable)

- When the part cannot be moved.

- When processes such as thermal sprays or welding are not acceptable.

Brush-plating systems are available for electroplating, anodizing and electropolishing. These systems vary in their degrees of sophistication and coating capabilities.

Small touch-up systems are used to apply cadmium, zinc-nickel, silver, gold or other deposits onto relatively small areas. Larger, more sophisticated systems use power packs with outputs up to 500 A and are capable of producing excellent quality finishes and high thicknesses on large surface areas.

Brush plating is a proven process that offers a high degree of flexibility to apply accurately controlled thicknesses of engineered deposits and coatings onto localized areas of metal components. Whether for OEM or repair applications, the portability, ease of use, and the minimal solutions required make brush plating an attractive option to consider.

Related Content

Conveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MoreHow to Address Declining Powder Coating Coverage Over Time

Fine particles from reclaim could be to blame for powder coating problems that emerge over time. Avoid problems by keeping hooks clean, maintaining guns and using reclaim powder quickly to avoid accumulation of fines.

Read MoreUnderstanding and Managing White Spots on Anodized Aluminum

Having trouble with spotting defects when anodizing? Taj Patel of Techevon LLC offers a helpful overview of the various causes of white spots and potential solutions.

Read MoreAlkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)