Disconnecting Cadmium

Sheffield Platers is in pursuit of what some may call the Holy Grail of connector plating: coming up with a suitable replacement for cadmium coatings on electrical connectors used by many U.S. military organizations.

Tucked away behind a row of swaying palm trees in a quaint industrial park about 10 miles from the resplendent Torrey Pines golf course on the breezy coastline of the Pacific Ocean sits a world-class plating shop at the leading edge of cadmium replacement technology.

Situated in what could arguably be one of the most picturesque settings for a high-tech plating shop, Sheffield Platers is in pursuit of what some may call the Holy Grail of connector plating: coming up with a suitable replacement for cadmium coatings on electrical connectors used by many U.S. military organizations.

“Our goal is to not only investigate the chemistries already in the marketplace, but to also introduce into testing our own multi-layer coatings we have worked on to replace the cadmium components,” says Dale Watkins, half of the brother ownership duo who has turned Sheffield Platers into one of the most well-respected shops in the U.S.

Dale’s brother Mark serves as vice president of the firm, which operates out of a 21,000-sq-ft facility that sits on just over an acre next to the Marine Corps Air Station in Miramar, outside of La Jolla, Calif.

SPECIALIZING IN CONNECTORS

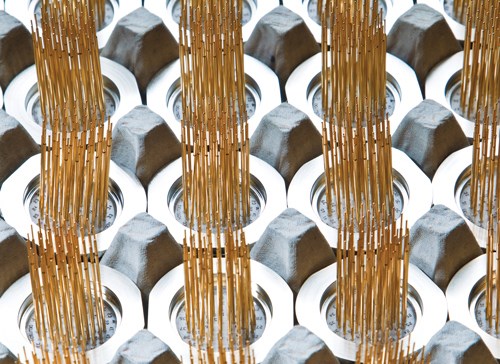

Sheffield Platers works both directly and indirectly for the military and defense industry, specializing in connectors such as aluminum back shells, coupling rings and hermetic connectors, and all the internal utility parts to build the connectors.

According to Dale Watkins, the most requested finishes are olive drab over cadmium (80 percent) and electroless nickel (20 percent); but therein lies the rub. Many electrical connectors currently used by Department of Defense ground systems contain cadmium or hexavalent chromium coatings, which are on their way out thanks to a 2007 presidential directive that ordered federal agencies to reduce the quantity of toxic and hazardous chemicals and materials.

That has left many chemicals manufacturers in the plating industry scrambling to find a suitable replacement and many of the top military agencies looking at new, environmentally friendly technologies for surface engineering. The Naval Air Systems Command, Naval Sea Systems Command, U.S. Army, U.S. Marine Corps, U.S. Air Force and the Defense Logistics Agency all have met with prime contractors such as Boeing, Lockheed, Raytheon and Honeywell at workshops led by Keith Legg, technical manager for Advanced Surface Engineering Technologies for a Sustainable Defense (ASETSDefense). ASETSDefense is a DoD initiative to facilitate the implementation of such new technologies.

“There are several cadmium alternatives that are moving towards production in different applications, but all of them have technical issues,” Legg said after a 2011 workshop.

MEETING DOD SPECIFICATIONS

That has led shops like Sheffield Platers to partake in its own laboratory research to come up with a cadmium replacement that meets the specification demanded of electrical connectors.

Those requirements include thickness between 0.0002-0.0008 inches; good throwing power for fine and coarse threads and complex geometries; minimum thread lubricity of 500 mating cycles; and coupling and uncoupling torque that continues to meet spec after exposure to severe corrosion environments.

According to a report after a 2012 ASETSDefense workshop on alternatives to cadmium plating, the most difficult cadmium application to replace is on electrical connectors that are found in every weapon system. “Besides meeting the corrosion requirements of components and the lubricity requirements of fasteners, connectors must also meet strict electrical conductivity requirements, even after corrosive attack,” the report says.

But that hasn’t dissuaded the Watkins and their long-time shop general manager, Steve Parkhurst, from working on a replacement to coat thousands of connectors every day.

“As we looked around for a replacement, we saw that there wasn’t a coating out there that met all the specified requirements,” says Parkhurst, a veteran of the industry who was one of the Watkins’ first hires several decades ago. “Most of the OEMs have gone through a few approved coatings, but they quickly realize that none of them are going to meet their requirements. It seems they got thrown in the specs a few years ago, and probably prematurely.”

CONFUSION AMONG OEMS

Confounding the issue is the confusion among the OEMs that are in need of a cadmium replacement.

“There is a slight disagreement among the OEMs as to what they should be using,” Dale Watkins says. “Is it Teflon nickel, is it zinc nickel? Or something else? They don’t quite know what direction they should be going in.”

Early cadmium alternatives were vacuum-deposited, ion-vapor deposited aluminum, as well as an electroplated aluminum developed by AlumiPlate in Minnesota, which required an airtight plating line. Both of these processes were fully qualified, ASETSDefense officials say, but they were limited because of cost and complexity.

When it comes to connectors, ASETSDefense says several specifications now permit pure aluminum, zinc nickel or nickel-fluorocarbon to be used in place of cadmium on steel and aluminum alloy connector shells.

“You’ve got people running one way, others running another way, and here we were trying to figure out which way we’re going to turn,” Watkins says. “So, we’ll focus on our own formula that we know works best for us and our partners.”

SPI CONNECTOR BLACK

Sheffield Platers is using chemicals from various suppliers to come up with a layered cadmium replacement it is confident will work just as good called SPI Connector Black.

That’s where Vincent Noonan comes in. The company’s director of business development spent most of his career in the chemical side of the plating industry before coming to work for Watkins. In addition to bringing in new business and growing the sectors in which Sheffield Platers was already working, Noonan will help launch and market SPI Connector Black as the shop’s proprietary cadmium replacement.

“We’re using various chemicals, but it’s our formulations,” says Noonan, who was a rep for numerous chemical suppliers in the past. “But it’s also our own system, the way we pretreat and the steps we follow. It’s our formulation, but what it comes down to is how we perform the process, and we do it very well.”

It wasn’t always smooth sailing for Sheffield Platers. After their father died in 1991, Dale and Mark were asked by their stepmother to take over the family plating shop, which was having big issues with local environmental agencies. The brothers each had other careers, but they decided to save the family business. Dale worked long days at the shop while maintaining his evening job as a chef at a local restaurant. Mark forged ahead to keep Sheffield Platers up and running

COMPANY TURNAROUND

Those two—along with Parkhurst—helped turn the company around and set it on a path to becoming one of the top aerospace and military coaters in the country.

Noonan says Sheffield Platers is in the testing phase for SPI Connector Black and has already plated parts that are in the salt-spray testing phase. Two OEMs salt-spray tested them to a passing grade, although the tests did not go all the way to 500 hours, but rather to a commercially acceptable level.

“Whatever we come up with, an OEM will eventually have to qualify it on their parts,” Parkhurst says. “It is a very lengthy process.”

Noonan says Sheffield Platers will be ready to offer SPI Connector Black to its customers within the next year, which he says will be perfect timing.

“Things are about to come to a head, and there is already a lot of anxiousness in the industry because they could come out tomorrow and say ‘no more cadmium,’” he says. “Personally, I think it may be another 10 years before cadmium is gone, but you never know.”

Either way, Watkins sees having the formulation and the knowledge that goes with having the company’s own cadmium replacement as a true benefit in its market position as a plating shop.

“When OEMs see that we did our own R&D and we didn’t just rely on the chemical companies, then I think that fact will open doors for us,” Watkins says. “We’re banking that this will bring us new and more business.”

For information about Sheffield Platers, please call 800-227-9242 or visit Sheffieldplaters.com.

Related Content

Products Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreA Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

Read MoreHow to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreRead Next

Environmentally Friendly Fastener Finishes

A research study was conducted on eight finishes that are potential replacements for cadmium. Information from the tests is specific to clamp load and corrosion, both cosmetic and galvanic...

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More