Dürr recently built a high-tech paint shop for Ford Motor Company in Hermosillo, Mexico. The new shop, which supports the production of a new Ford vehicle, uses modern technology, digital solutions and local climate conditions to attain high painting quality.

The new paint shop includes low and high viscosity material supply systems, robotic paint and sealer application equipment and other process automation technology. In addition to using two painting booths for a three-wet process, Ford uses a dedicated booth for two-tone painting via masking. Dürr says that arranging the two-tone coating separately creates flexibility and ensures the highest efficiency of the coating line.

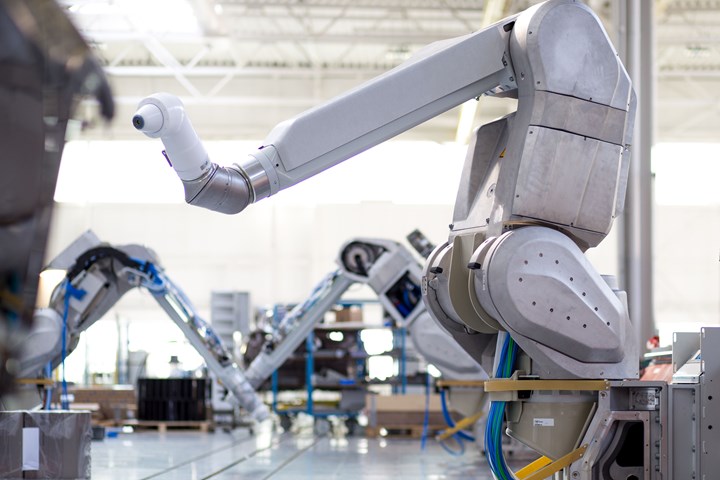

Dürr’s EcoRP E033i painting robots perform the automatic exterior coating of primer, base and clear coat in all painting booths. Dürr’s EcoRP S153i swingarm robots then base-coat the interior cargo areas. With its highly mobile swingarm, the robot can apparently reach surfaces several meters away, as well as hard-to-reach areas in the interior. According to Dürr, the modularity of these robots, which were designed specifically to paint commercial vehicles, allows for high flexibility and improved robustness. For the two three-wet topcoat painting booths, Ford opted for the EcoEnvirojet wet scrubber technology.

Taking advantage of the heat

One distinctive detail of the plant is that it takes advantage of Hermosillo’s high temperatures and dry weather during most of the year. The e-coat, sealing, two-tone and topcoat Ecopaint ovens are installed outside and use the high ambient air temperature for energy efficient heating. The ovens are equipped with Dürr’s recuperative thermal oxidizer Oxi.X TR, an elimination system for volatile organic compounds that, according to the company, is the most efficient, cost-effective method of air purification. The modular ovens are located outside in a U-turn layout so the car bodies can leave the building, go through the ovens and then return indoors.

Increasing transparency through digital solutions

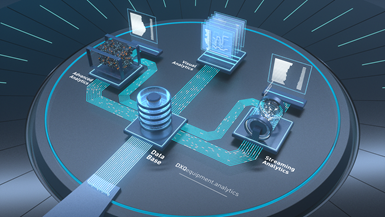

Dürr's scope of supply also includes the digital solutions DXQplant.monitoring and DXQequipment.analytics, which reportedly provide greater visibility of factory and equipment data while achieving significant downtime reduction. The analysis software, DXQequipment.analytics, evaluates all robot and process data down to the millisecond, enabling operators to quickly identify and rectify faults. The system also includes a streaming analytics application for real-time data analysis.

Establishing modularity and automation

Dürr also installed phosphate and electro dipcoating tanks equipped with Ecopaint PT/EC pendulum system, as well as the modular anode control EcoDC MACS. Dürr says the modular design of this anode control protects the system from failures. Due to multiple rectifiers, the system enables an individual setting of voltage for each car body type.

The sealing line includes manual and automated zones. Four EcoRS 30 L16 sealing robots and two EcoRS 16 overhead handling robots are installed in the liquid-applied sound deadener zone, while the underbody sealing zone is equipped with two EcoRS 16s. Dürr says the robots ensure a safe, reliable performance through strategically located sensors that help to avoid errors and collisions.

According to Dürr, the creation of the new paint shop represents the largest order that Ford has given to the company in Mexico. “We are proud that Ford has given us the opportunity to realize highly efficient concepts, and cutting-edge technologies from Dürr,” states Sandro Picchio, CEO of Dürr Mexico. “We support Ford’s production process with the highest quality standards, the most cost-effective units and lowest environmental impact.”

Related Content

Finishing High Reliability, Function Critical Parts

From safety critical automotive and aerospace components to lifesaving medical micro-components and implantable devices, Indiana-based Electro-Spec finishes applications that require zero failure rates.

Read MoreHenry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreCobot Enters Paint Industry With Safety at the Forefront

This collaborative robot is the first explosion-proof solution for the powder coating and paint arena that meets the U.S.’ stringent safety requirements. Its lead-through teach programming and tablet control are especially appealing to small shops with little proficiency in robotics.

Read MoreCoatings Plant Evolves with Market Trends

Expanding its focus from exclusively serving the RV industry, one of this company’s stand-alone coatings plant has successfully extended its services to additional markets.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)