Electrodeposition of Ni-Fe-Mo-W Alloys - Part 10

Tenth Quarterly Report - AESF Research Project #R-117. This NASF-AESF Foundation research project report covers the tenth quarter of project work (April-June 2015). In this period, Graduate student Avinash Kola has continued work on the influence of deposition conditions on the properties of the Ni-W alloys.

by

Prof. E.J. Podlaha-Murphy* and A. Kola

Northeastern University

Boston, Massachusetts, USA

Editor’s Note: This NASF-AESF Foundation research project report covers the tenth quarter of project work (April-June 2015). Progress on the previous quarters has been published in summary in the NASF Report in Products Finishing and in full at www.pfonline.com.** A printable PDF version is available by clicking HERE.

Introduction

The project, initiated in January 2013, addresses the induced codeposition of molybdenum and tungsten alloys with nickel and iron having a focus on developing a toolbox of plating conditions to deposit different combinations of Ni, Fe, Mo and W. This paper covers progress made during the tenth quarter.

In previous reports, the effect of 2 butyne-1,4-diol (BD) on Ni-W plating from an ammonia-free electrolyte at pH 2 and 8 were examined. In both cases the addition of BD concentration in the electrolyte caused a lower current efficiency, but an expected smoother deposit surface. In this report, the addition of boric acid was investigated to examine, in particular, if the current efficiency can be improved in the presence of BD, and if, in turn, the addition of boric acid affects the deposit composition.

Boric acid is known to be a good buffering agent,1 has been shown to enhance the deposition rate of nickel by lowering its overvoltage2,3 and can help to suppress the hydrogen evolution side reaction.4-6 Thus, it would be expected to improve current efficiency. Electrolytes used to electrodeposit Ni-W thin films typically contain ammonia. Electrolytes without ammonia have been developed, with a large quantity of tungsten in the deposit, but at a loss of current efficiency.7-11 In previous reports from our lab, Ni-W thin films and nanowires were successfully deposited in an ammonia-free, boric acid-citrate electrolyte.12 The motivation to use boric acid was adopted from previous literature reports of using boric acid in Co-W electrodeposition.13,14

In Ni-W electrodeposition from ammonium containing electrolytes, Donten, et al.15,16 included boric acid in the electrolyte to obtain amorphous tungsten-alloys with nickel, iron and cobalt, though the effect of boric acid was not explicitly studied. Wu, et al.17 comprehensively examined the effect of boric acid addition on the deposit composition, structure and hardness of electrodeposited Ni-W with a plating bath containing ammonium salts. They showed that the tungsten content increased gradually with increasing boric acid electrolyte additions, with a parabolic change in current efficiency. The Ni-W current efficiency was improved between with an addition of 0 to 0.5 M boric acid, and then decreased as the boric acid concentration was further increased. Grain refinement was observed with the increase in the boric acid electrolyte, with an accompanying composition increase in wt% tungsten. Improved hardness of the deposit was correlated with a decrease in the grain size up to a point. It then fell with higher wt% tungsten. Thus, it is possible, based on these studies, that there may also be an influence of boric acid on the deposit composition with an ammonia-free electrolyte. To this end, the electrodeposition of Ni-W is examined in an ammonia-free electrolyte, pH 8, with the addition of the following amounts of boric acid: 0, 0.5 and 1.0 M.

Experimental

A traditional Hull cell with air agitation was used to deposit Ni-W alloys from an ammonia-free electrolyte. The electrolyte contained 0.1 M nickel sulfate, 0.15 M sodium tungstate, 0.285 M trisodium citrate, 5 mM BD and variable amounts of boric acid, at a pH of 8 and at room temperature (RT), 22-23°C. Further, the influence of temperature was considered by inspecting one condition at 60°C, with the electrolyte containing 0.5 M boric acid. The average applied current density was -50 mA/cm2 on a copper plate, and with an agitation rate of 3 L/min created from the use of air jets near the cathode surface. The deposition time was 30 min. Polarization data was obtained by placing the electrodes parallel to each other using a three-electrode cell configuration with a Ag/AgCl reference electrode. The scan rate of potential was 10 mV/sec. The curves were corrected for ohmic drop with impedance spectroscopy (not shown). Composition and thickness were measured using x-ray fluorescence (XRF).

Results and discussion

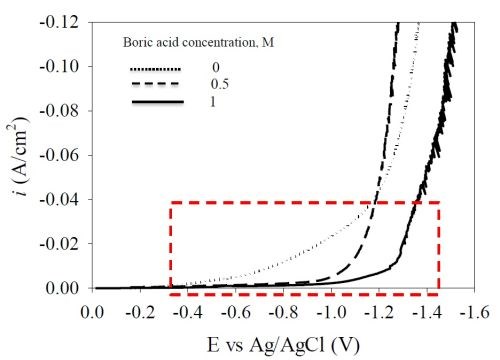

The polarization curves in Fig. 1 show that there is an influence on the total current density with boric acid concentration at room temperature. With increasing concentrations of boric acid, there is an inhibitory effect on the total current in the potential range of -0.6 to -1.2 VAg/AgCl (see dashed region in box) at low current densities. Above a cathodic current density of 50 mA/cm2 the total current density doesn’t follow a trend with the addition of boric acid. There is a sharp increase in current density for the 0.5 M boric acid case at a potential of about -1.1 V, indicative of the exponential increase in water reduction, while for the 1.0 M boric acid case the rise in current density occurs at more negative potential values. A closer look at the partial current densities helps to understand whether the metal or side reaction partial current density, or both, is affected by the boric acid addition. In order to determine the partial current densities the deposition composition and mass were evaluated.

Figure 1 - Polarization curved with different amounts of boric acid added to the Ni-W electrolyte, at a pH 8, at room temperature.

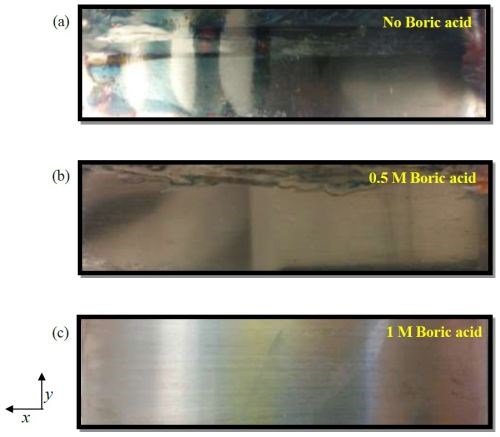

The Hull cell was used to deposit the alloy over a large range of current density, (assuming a primary current distribution, and confirmed in previous reports via a measure of the Wagner number). Figures 2(a-c) show the Ni-W deposits obtained on a Hull cell, with an expected current distribution for different amounts of boric acid in the electrolyte. The low current density is at the right end of the plate, while the high current density is at the left, varying in the x-direction. As observed optically, all the deposits appear reflective. When there is no boric acid present, Fig. 2(a), the deposit contains streaks in the y-direction that match the flow pattern of the air agitation. With the addition of boric acid, Figs. 2(b) and (c), the visual air patterns were greatly reduced and a more uniform deposit is presented.

Figure 2 - Ni-W Hull cell cathodes in electrolytes with a (a) 0, (b) 0.5 and (c) 1.0 M boric acid addition to the electrolyte (low to high current density, from right to left), at room temperature.

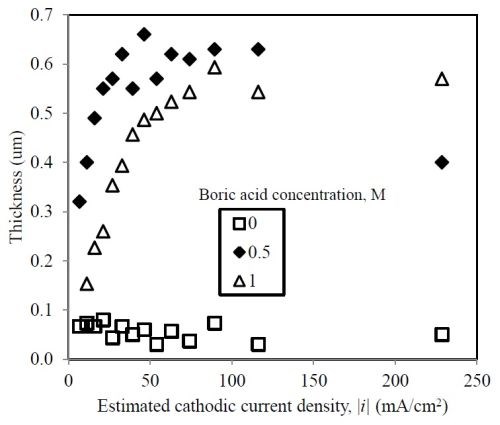

The deposit thickness and composition, was measured by XRF, scanning across the electrode surface, and assuming that the densities of nickel and tungsten were bulk values. Figures 3 and 4 show the deposit thickness and composition, respectively, as a function of the estimated local current density. The local current density, i, at each normalized position, x, was determined by assuming a primary current distribution according to West, et al.18

(1)

where iavg is the average applied current density, in this case, -50 mA/cm2.

In Fig. 3, the deposit thickness is represented as a function of the estimated current density from equation (1). There is a significant increase of the thickness with the addition of boric acid, and hence, the current efficiency increases.

Figure 3 - Effect of boric acid concentration on deposit thickness at room temperature.

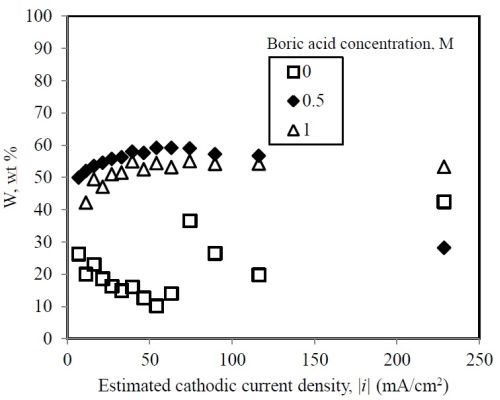

Figure 4 - Tungsten deposit composition of the alloy with different concentrations of boric acid in the electrolyte at room temperature.

The deposit composition is presented in Fig. 4, based on an analysis of only the heavy metals (Ni, W, Cu substrate). The light elements (possibly, S, C, N and O) are not captured by the XRF calibration and measurement. Figure 4 shows that there is a large enhancement in the amount of tungsten in the deposit with the addition of boric acid. The increase in tungsten is relatively insensitive to the amount of boric acid, with very small changes (~ 1-2%) of the wt% tungsten between 0.5 and 1.0 M boric acid concentration in the electrolyte.

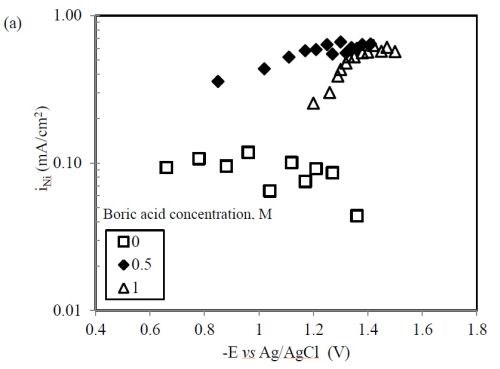

Figure 5 - Partial current densities with varying concentrations of boric acid for (a) nickel and (b) tungsten at room temperature.

Applying Faraday's law, the steady state metal partial current densities are determined from the thickness and composition data. Figure 5 shows these values for (a) nickel and (b) tungsten under different concentrations of boric acid. There is a substantial increase in the metal ion partial current densities when boric acid is added to the electrolyte. There is also a small shift in the metal deposition potential to more negative values with increasing boric acid concentration as similarly observed in Fig. 1. A notable feature is that in the presence of boric acid, the tungsten partial current density has the same shape as the nickel partial current density, showing a limiting case for the tungsten reduction - that it is coupled to the nickel reduction rate. When boric acid is not present, the tungsten partial current density appears to be inhibited with increasing polarization (or appied current density) that may be due to the adsorption of hydrogen species, lowering the amount of tungsten in the deposit. Thus, it is suspected that the reason there is more tungsten in the deposit with boric acid is that it may be due to less adsorbed hydrogen.

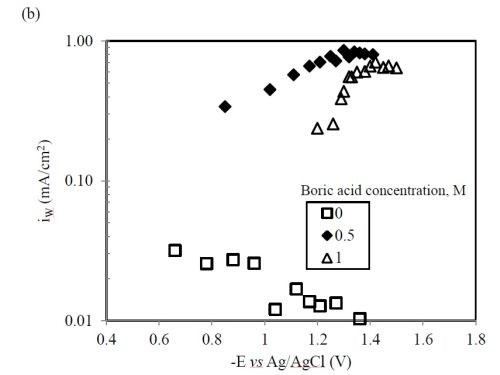

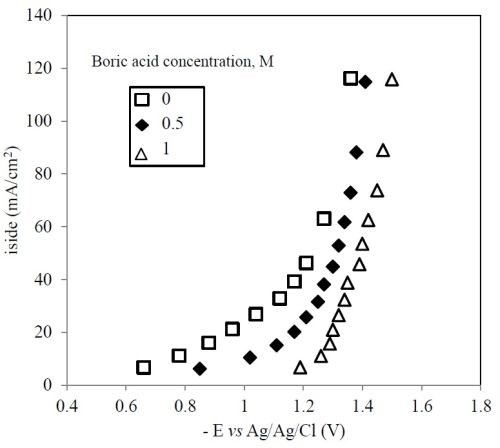

Figure 6 shows the side reaction partial current density that is estimated by assuming that the total current density follows equation (1), and is determined by taking the difference between this total current density and the sum of the metal partial current densities. The side reaction decreases with the addition of boric acid, contributing to an enhancement in current efficiency.

Figure 6 - Hydrogen evolution side reaction partial current densities with varying concentrations of boric acid, at room temperature.

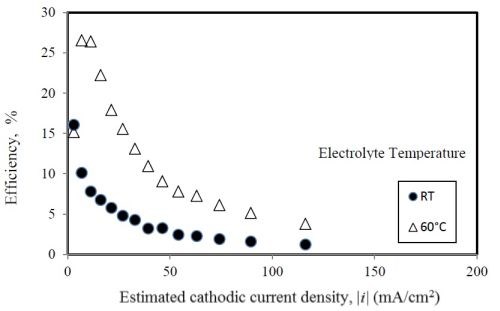

Even with the addition of the boric acid into the electrolyte, the best current efficiency obtained in this ammonia-free electrolyte formulation at room temperature is low, roughly 10-15% (Fig. 7) at low applied current density. In an effort to increase the current efficiency, the electrolyte temperature was increased. An increase in temperature does not always guarantee an improvement in the current efficiency, as the increased heat can also enhance the side reaction.

Figure 7 - Effect of temperature on the cathodic current efficiency, 0.5 M boric acid

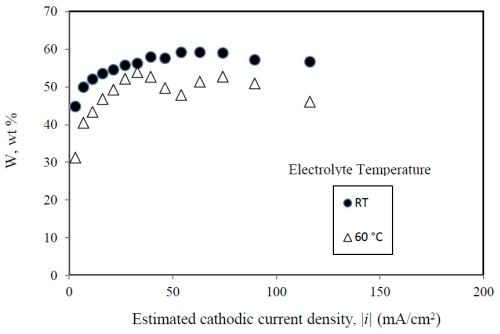

Using a Hull cell with the same applied average current density, air agitation and electrolyte composition, but at a temperature of 60°C, the alloy was found to have slightly less tungsten in the deposit compared to the deposition at room temperature, as presented in Fig. 8. Elevating the temperature did, however, greatly improve the current efficiency with a 0.5 M boric acid concentration (Fig. 7). The current efficiency at the elevated temperature compared with room temperature increased from ~10 % to ~25 % at low applied current densities. At higher current densities, the side reaction becomes excessive and the current efficiency is nearly the same for both temperatures. In addition, the deposit over the Hull cell was noticeably more reflective at the higher electrolyte temperature.

Figure 8 - Effect of temperature on the deposit composition, 0.5 M boric acid

Conclusions

In a continuing report of Ni-W electrodeposition with the additive of 2 butyne-1,4-diol (BD), the amount of boric acid was varied, assessed by using a conventional Hull cell with air agitation. The added boric acid in the electrolyte significantly increased the amount of tungsten in the deposit and improved current efficiency. The increase in the deposit tungsten composition was a consequence of an increase in the tungstate reduction rate. The nickel ion reduction rate also increased with boric acid, although not as much as the tungstate reaction, contributing also to an improved current efficiency. Elevating the electrolyte temperature significantly improved the efficiency with nearly the same amount of tungsten in the deposit.

This work was presented, in part, at SUR/FIN 2015:

A. Kola and E. Podlaha “Ni-W Electrodeposition with BD and Boric Acid," Proc. SUR/FIN 2015, Rosemont, IL, June 2015.

References

1. J. Ji, et al., J. Appl. Electrochem., 25 (7), 642-650 (1995).

2. J.P. Hoare, J. Electrochem. Soc., 133 (2), 2491-2494 (1986).

3. J.P. Hoare, J. Electrochem. Soc., 134 (12), 3102-3103 (1987).

4. J. Horkans, J. Electrochem. Soc., 126 (11), 1861-1867 (1979).

5. Y. Tsuru, R. Takamatsu, and K. Hoskawa, J. Surf. Finish. Japan, 44 (1), 39 (1993).

6. Y. Tsuru, M. Nomura, and F. R. Foulkes, J. Appl. Electrochem., 32 (6), 629-634 (2002).

7. M.D. Obradović, et al., J. Serb. Chem. Soc., 66 (11-12), 899-912 (2001).

8. M. Donten, H. Cesiulis and Z. Stojek, Electrochim. Acta, 45 (20), 3389-3396 (2000).

9. I. Mizushima, et al., Electrochim. Acta, 51 (27), 6128-6134 (2006).

10. O. Younes and E. Gileadi, Electrochem. Solid-State Letters, 3 (12), 543-545 (2000).

11. N. Eliaz, T.M. Sridhar and E. Gileadi, Electrochim. Acta, 50 (14), 2893-2904 (2005).

12. T. Bairachna, W. Fowle and E. J. Podlaha, ECS Trans., 41 (21), 29-34 (2012).

13. N. Tsyntsaru, et al., Trans. Inst. Met. Finish., 86 (6), 301-307 (2008).

14. Z. Abdel Hamid, Mater. Letters, 57 (16-17), 2558-2564 (2003).

15. M. Donten, H. Cesiulis and Z. Stojek, Electrochim. Acta, 45 (20), 3389-3396 (2000).

16. M. Donten, Z. Stojek and H. Cesiulis, J. Electrochem. Soc., 150 (2), C95-C98 (2003).

17. Y. Wu, et al., Surf. Coat. Technol., 173 (2-3), 259-264 (2003).

18. A. C. West, M. Matlosz and D. Landolt, J. Appl. Electrochem., 22 (3), 301-303 (1992).

Footnotes

*Corresponding author:

Prof. E.J. Podlaha-Murphy

Professor of Chemical Engineering

Northeastern University

Boston, Massachusetts 02115

Phone: (617) 373-3796

E-mail: e.podlaha-murphy@neu.edu

**Quarter 1 (January-March 2013): NASF Report in Products Finishing; NASF Surface Technology White Papers, 78 (1), 11-17 (October 2013); http://short.pfonline.com/NASF13Oct2.

Quarter 2 (April-June 2013): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 78 (2), 18-27 (November 2013); http://short.pfonline.com/NASF13Nov2.

Quarter 3 (July-September 2013): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 78 (4), 11-16 (January 2014); http://short.pfonline.com/NASF14Jan2.

Quarters 4-6 (October 2013 - June 2014): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 79 (2), 1-14 (November 2014); http://short.pfonline.com/NASF14Nov1.

Quarter 7 (July - September 2014): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 79 (7), 1-9 (April 2015); http://short.pfonline.com/NASF15Apr1.

Quarter 8 (October - December 2014): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 79 (10), 1-8 (July 2015); http://short.pfonline.com/NASF15Jul1.

Quarter 9 (January-March 2015): Summary: NASF Report in Products Finishing; NASF Surface Technology White Papers, 79 (11), 1-10 (August 2015); http://short.pfonline.com/NASF15Aug1.

About the authors:

Avinash Kola is a Ph.D. student in the Department of Chemical Engineering at Northeastern University. He received his M.S in Chemical Engineering at Louisiana Tech University in 2010, and his B.S from Jawaharlal Nehru Technological University, India in 2006.

Related Content

Alkaline Cleaning Guide

Gregg Sanko, Senior Chemist, Oakite Products, Inc. provides an overview of the alkaline cleaning process.

Read MoreAn Overview of Electroless Nickel Plating

By definition, electroless plating is metal deposition by a controlled chemical reaction.

Read MoreHow to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreUnderstanding and Managing White Spots on Anodized Aluminum

Having trouble with spotting defects when anodizing? Taj Patel of Techevon LLC offers a helpful overview of the various causes of white spots and potential solutions.

Read MoreRead Next

A ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More

.jpg;maxWidth=300;quality=90)