NASF leaders have submitted a 100-page package of comments to the U.S. Environmental Protection Agency in response to the agency’s proposed rule for chromium finishing operations. In it, the NASF questions the agency’s decision to tighten tough regulations even further when the industry has reduced emissions by 99.9 percent since 1995.

EPA Used Data from “Phantom Facilities”

The comments also point to major flaws in EPA data and analysis and raise concerns over EPA’s approach to the rule that, if left unchallenged, will pose problems for the broader finishing industry in the future.

“Unfortunately, EPA’s analysis has dramatically overestimated both emissions and potential risks from the industry,” says Jeff Hannapel, of NASF Government Affairs.

“This is not a favorable precedent. The actual data we’ve received from NASF members across the U.S. show that EPA counted emissions incorrectly, and a majority of companies shown as emitters on the agency’s list either don’t exist, don’t do chromium or have actual emissions far below EPA’s ‘models’ driving the new regulation,” Hannapel says.

NASF Comments to EPA: Executive Summary

NASF has raised a number of issues with the rule, including the following concerns:

EPA has unjustifiably reversed its earlier position on the rule. In this supplemental proposal, EPA concludes that the residual risks associated with the chromium electroplating and anodizing industry are lower than the agency estimated in the October 2010 proposal. EPA, however, inexplicably proposes to impose more stringent surface tension levels and emission limits based on technology and additional controls that it now claims can reduce risks at reasonable costs. This about-face makes no sense, particularly in light of the further information that NASF is providing.

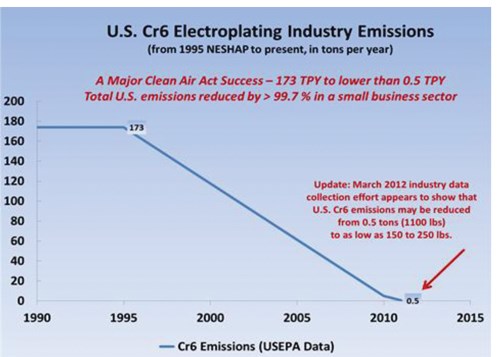

The industry has already reduced emissions by more than 99.7 percent. For context, over the past 15 years, the surface finishing industry has dramatically reduced chromium emissions. Since 1995, the industry has reduced nationwide emissions of chromium from 173 tons to at least EPA’s conservative current estimate of 1,140 lbs—a reduction of 99.7 percent.

Actual industry data show much lower emissions. The actual emissions associated with the industry are significantly lower than EPA emissions estimates. NASF’s newly collected data and analysis indicates that a more accurate estimate of current emissions is approximately 200 lbs a year, or 80 percent lower that EPA’s estimate—and a 99.9 percent reduction since 1995. Such reductions in emissions and the associated risks represent an environmental policy success story that should be acknowledged and celebrated. Instead, EPA is proposing more stringent new limits on the industry.

Further emission reductions are unnecessary and newly added costs are unreasonable. Because actual emissions are so much lower than EPA’s conservative estimate, there is no justification for imposing the stringent limits included in this proposed rule. The risks posed by emissions from chromium electroplating and anodizing operations are miniscule and have been deemed acceptable by EPA, so further reduction of emissions is unnecessary and the cost of attempting to achieve additional reductions is unreasonable.

EPA data underpinning the rule contain major errors and outdated information. There are significant quality problems with the data underpinning this rule. While EPA now has more data that it had for the October 2010 proposal, most of this data is still outdated, incomplete, inaccurate and unreliable. In addition, there are numerous inconsistencies in the data. As NASF has continued to review the data, in the limited time available, it continues to identify errors and outdated information. The number and scale of the problems completely undercut the validity of the proposed rule.

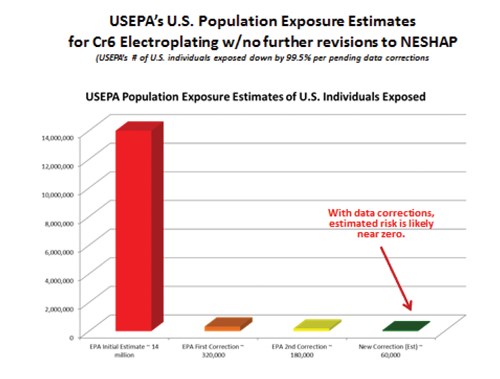

The majority of facilities in EPA’s database are closed, do not process chromium or have lower emissions vs. EPA’s modeled data. In order to check the reliability of EPA’s data, NASF reached out to its members and requested information on approximately 300 of the highest emissions facilities identified by EPA. Over a third of those facilities have responded to date and these responses indicate that actual emissions are 94 percent lower than EPA’s estimates.

Of the facilities that responded or for which new information was collected, 35 percent were found to be closed, 38 percent no longer—or never did—process chromium, 25 percent provided data that showed emissions lower than EPA’s estimate, and only 2 percent actually confirmed EPA’s emissions estimate.

In addition, EPA’s emissions and dispersion modeling for hexavalent chromium are systematically biased high compared with actual monitoring data collected by EPA, leading to an over-estimation of ambient concentrations (and risks) at those sites where higher concentrations are modeled.

EPA has committed procedural errors and has not allowed industry to complete its analysis and provide meaningful comment. Despite the fact that NASF raised significant concerns about the data and other aspects of the proposed rule, EPA denied NASF’s request for an extension of the comment period. This has left NASF and others with insufficient time to fully and meaningfully comment on this proposed rule. In addition, EPA should have, but did not, conduct a Small Business Regulatory Enforcement Fairness Act (SBREFA) panel review of this rule pursuant to its obligations under the Regulatory Flexibility Act.

EPA reversed the sequence of proper analytical steps under the clean air act. EPA’s regulatory approach in this rulemaking reversed the proper analysis under the Clean Air Act. Had EPA first evaluated the existing standards under 112(f), it should have concluded that those existing standards were appropriately protective, because it reached precisely that conclusion in October 2010, and EPA in this proposal concludes that the risk is even lower than what it believed then. There was no need to conduct a section 112(d)(6) review. Though, in any event, the record does not support a lower standard based on such a review section 112(d)(6), as EPA did not identify practices, processes, or control technologies that warrant stricter standards.

EPA has little or no data to show that non-PFOS fume suppressants are equivalent to PFOS fume suppressants. The technology that EPA is proposing to require—non-PFOS fume suppressants—is a technology in transition, has not been proven effective in all instances and is not simply a drop-in replacement for PFOS fume suppressants. Even more troubling, EPA has provided no data in the record that non-PFOS fume suppressants can achieve the proposed new surface tension levels. EPA assumes that non-PFOS fume suppressants are equivalent in performance without presenting any scientific proof or supporting data.

For all of these reasons, and as discussed in more detail in our full comments, EPA must fundamentally reconsider these proposed regulations. NASF welcomes the agency’s approach proposed in the October, 2010 proposal but believes that the stricter regulations included in this proposal are arbitrary, capricious and unsupported by the record.

National Association for Surface Finishing