Paul Brancato Leads Epner and NASF

Epner Technology co-owner is tapped as new NASF president. His main goal is to improve communications to its members and those who are non-members.

On a sparkling sunny day in Brooklyn, Paul Brancato steps out of his office at Epner Technology on Kingsland Avenue and walks at a brisk pace down the street to the building that houses the company plating lines just two blocks away on Division Place, a three-minute jaunt that puts a smile on his face as he strolls past row houses and turns right at “My Favorite Cleaners” to reach a brownstone where the magic happens.

“I love this neighborhood,” says Brancato, in his unique accent that doesn’t hide where he came from and where he still calls home.

For the past 30-plus years, Epner Technology has been his home in the plating world, where he has worked on everything from the most top-secret defense systems and NASA projects, to working with some of the most famous artisans in the world who come to Brooklyn to get their works of fine art plated in a variety of finishes.

While things have pretty much stayed the same for Brancato over the past four decades since graduating from Manhattan College with a chemical engineering degree, something new is in the air as the vice president of Epner Technology moves into the president’s seat for the National Association for Surface Finishing in 2017.

A vice president to Coventya’s Erik Weyls the last few years, Brancato takes over not only as the leader of the NASF, but also in a more formidable role with Epner Technology, whom he shares ownership with the legendary David Epner, Stephen Candiloro Jr., the vice president of operations whose father, Stephen, was David’s long-time partner before passing away in 2009, and Dariusz Gustek, a staff chemist.

Improved Communications

Brancato is excited as he ramps up for his first Sur/Fin Manufacturing and Technology Trade Show and Conference in June as president of NASF. His main goal is to improve communications to its members and those who are non-members.

“As the owner of a job shop, I think I have a very unique perspective on things when it comes to how the association is presenting its message,” he says. “I think from a national board, and from our committees, and from the Policy Group that we hire, the message is just not getting out there well enough, not just for our 400 job shops, but for our entire 700-plus members.

“There is a lot that has been going on—and certainly things that are being improved on—that is just not being communicated. We need to get the word out there about all the things that we are doing.”

Brancato says that lack of understanding of what the NASF is doing for its members was especially prominent when new board members joined in January and met with Brancato and others to bring them up to speed on programs and issues the NASF is working on.

“We brought some of those new board members in early, and after we finished going over everything, one of them said to me, ‘I’ve been on the Sur/Fin committee for years and have been very active, but I still had no idea how much was being done here nationally,’” he says. “That’s the problem I want to fix, once we get the message out about all that we are doing, then I think maybe we can grow the numbers.”

Brian Harrick of KC Jones Plating in Michigan is vice president of the NASF. Steve Brown of BroCo Products in Ohio is secretary. Board members recently elected to a two-year term are Curtis Goad of the Goad Co., Bernie Haviland of Haviland Products, Brad Majoy of Pavco and Jim Miille of Chemical Solutions; three new board members are Waasy Boddison of American Plating Power, Jeff Brassard of Palm International and Charles Morgan of Triple Cities Metal Finishing. The remaining board members are Rebecca Bennett of Precision Plating, Phil Brockman of Techmetals, Chris Capalbo of New Method Plating, LaVaughn Daniel of Danco Metal Surfacing, Kyle Hankinson of KCH Services, Steve Kocka of Atotech USA, Mitch Marsh of Finishing Services and James Sullivan of Schumacher Companies.

Working Collaboratively

Brancato joined Epner Technology in 1983 right out of college, and was hired as the quality manager. At night, he also attended New York University to earn his master’s degree. David Epner—son of the company founder—took a liking to Brancato’s work ethic and promoted him to operations and production manager in 1991.

Two years later, Epner and his partners approached Brancato about becoming a part-owner of the plating company, a chance he did not pass up. Since then, Brancato has moved up to become general manager of the company, and added the title of vice president in 2008.

“Paul has been very instrumental in the success we have had as a company,” says Epner, who is 84 and still active in the shop’s operation. “We all work very well together here; JR brings his skills, and Paul his and Dariusz his, and then there is me. We all enjoy what we do, and that is important.”

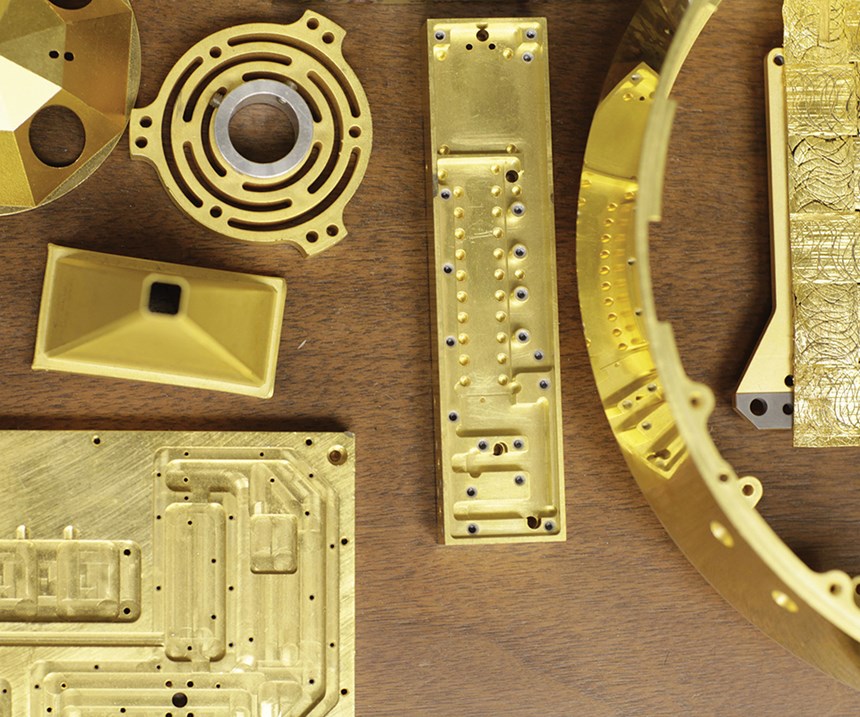

The foursome has led a team of chemists and line staff that has developed Epner Technology’s proprietary 24-karat hard gold process—Laser Gold—which caught the attention of most leading applications engineers not just in the U.S., but worldwide.

Epner says the secret was to achieve the theoretical infrared (IR) reflectivity and ultra-low emissivity of pure gold, while also making it three times as hard—not easy to pull off. But they did it, and Epner is now a primary plating source for manufactured cutting-edge IR instruments that orbit the earth, with clients such as NASA, Raytheon and Lockheed Martin.

Of course, Epner has made national news for being a boutique plating shop that also takes on high-profile plating jobs like the Academy Award statuettes and projects from world-renown artists.

Growing, Expanding

Stephen Candiloro Jr., who goes by JR, follows closely in the footsteps of his father, who was what David Epner called the “technical heart” of the team that first got the shop noticed.

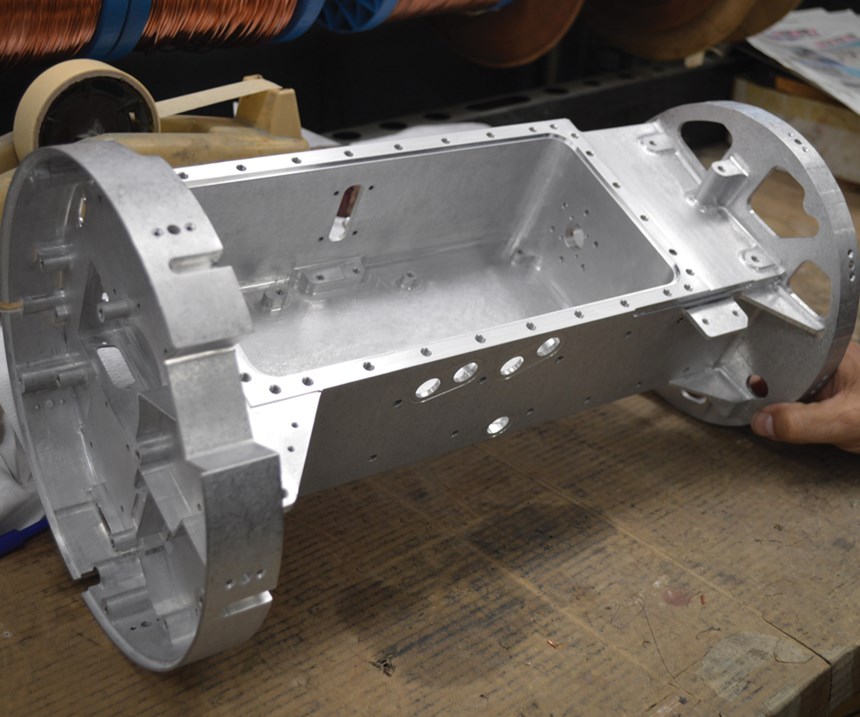

He says he likes the challenges that can walk in the door any day, whether a highly-technical piece for an aerospace company, or a sculpture artist who needs help with a finish.

“It happens every day, and all day long,” Candiloro says of the variety of work that shows up at Epner. “You just never know what walks in or the call you might get. It keeps us on our toes, but it is extremely gratifying to work on and solve these complex issues, whether it is NASA or an artist.”

Candiloro has learned that the faster he and his team can get involved in the engineering of a project, the better, making it easier for Epner Technology to suggest design and surface changes to parts if need be.

“Most of the time we can get the job done for them very easily, but often it takes a lot of conversation and back-and-forth to do the best job we can for the customer,” he says. “But we rarely turn anyone away. We try so hard to make it work for them, either on price or what it is they want, especially if it is a unique project or request. Those are the challenges we like.”

Soon, Epner Technology will have additional space to do its magic, as the company is planning an expansion project that will move its corporate offices closer to the facility where the plating lines are located.

The shop is building a new facility behind its current footprint, where it will house additional machining capabilities, more coating areas and office space. The team is working with local governing agencies and hopes to have it completed by Spring 2018.

“The office space will be vital because of all the meetings and planning we do with our customers,” Brancato says.

“We have a large number of visitors that need to come here and meet with us, so it will be very nice to have a place right next to the plating operation where we can meet and get involved with helping engineer a project to their satisfaction and ours.”

That will leave Brancato even busier this year as he plans and supervises the expansion project, and sees a wider role as NASF president. But he realizes that he's taking over leadership of an operation that has strengthened in recent years thanks to past presidents Michael Siegmund, Tony Revier, Rick Delawder and Weyls.

His focus, he says, is reaching out to expand membership and let existing members know what their national association is doing for them. By doing that, he hopes to get more involvement from the rank and file.

“An educated member is an effective and productive member,” Brancato says.

For information, visit epner.com or nasf.org.

Originally published in the May 2017 issue.

Related Content

Innovation in Plating on Plastic

Plating on advanced plastics solution offers improved adhesion, temperature resistance and cost savings.

Read MoreA Chromium Plating Overview

An overview of decorative and hard chromium electroplating processes.

Read More3 Tests to Ensure Parts are Clean Prior to Plating

Making sure that all of the pre-processing fluids are removed prior to plating is not as simple as it seems. Rich Held of Haviland Products outlines three tests that can help verify that your parts are clean.

Read MoreHow to Maximize Nickel Plating Performance

The advantages of boric acid-free nickel plating include allowing manufacturers who utilize nickel plating to keep up the ever-changing regulatory policies and support sustainability efforts.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read More