Preventing Solvent Pop

Preventing solvent pop on an industrial paint line...

Our Research and Development Center at Akzo Nobel Coatings, Inc., recently ran an experimental design for a client who manufactures and paints heavy-duty equipment. We needed to determine the optimum factors for increasing paint film thickness without solvent popping occurring. Our client wanted us to make sure that painted panels exited the ovens hard and cured, without any film blistering or softness.

Using design of experiments (DOE), Akzo performed a five-factor, two-level, 16-experiment design. We evaluated the five factors and their 10, two-factor interactions by taking an average of the eight high and low responses for each of the 15 factors and their interactions. The factors and levels are shown in Table I.

The experimental design and analysis work was simplified by using DOE software named Design-Ease® (Stat-Ease, Inc., Minneapolis, Minnesota). The software allowed us to consider all factors simultaneously by revealing how interconnected factors responded over the range of values.

| TABLE I—These Factors and Levels Simulate the Client's Industrial Production Line | ||

| FACTOR | LOW LEVEL (-) | HIGH LEVEL (+) |

| A: Convection oven temperature (F) | 100 | 200 |

| B: Infrared oven temperature (F) | 125 | 300 |

| C: Accelerator Per drum (ml) | 850 | 1000 |

| D: Activator type: Polyisocyanates | A | B |

| E: Convection oven air flow | Blocked | Open |

The designed experiment simulated our customer's paint curing ovens so we could determine the best settings for reducing solvent pop. The solvent pop response was measured as the film thickness at which popping began. The desired outcome was to have high, tack-free film build without any popping. In particular, we needed to pay careful attention to the grueling factors encountered during the hottest part of summer. This is the time of year when solvent pop is most common, especially in a facility that is not climate controlled—such as our client's. Popping occurs more frequently in hotter environments as film thickness increases. Therefore, it is important to carefully control the ovens to avoid solvent popping. The film coatings must endure extremely harsh conditions, year after year, in all types of soil, weather and temperatures. The coating's function is to protect heavy-duty specialty outdoor equipment.

Manipulating factors to attain an ideal response. Our objective was to vary and test important factors for solvent pop. We began by preparing eight, one-inch by four-inch test panels, then ran the panels through our laboratory simulation paint line. The simulated procedure was as follows:

A.Apply with airless sprayer 1.0 -1.5 dry mils of primer on all eight panels.

B.Flash for six minutes.

C.Apply two coats of paint onto the eight panels.

D.Remove one panel.

E.Apply one coat of paint onto the remaining panels.

F.Continue removing one panel and applying a coat of paint to the remaining panels until they contain between two coats (low film thickness) and nine coats (high film thickness) of topcoat.

G.Flash for six minutes.

H.Cure in convection oven for 12 minutes.

I.Cure in infrared oven for 12 minutes.

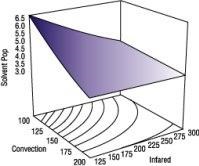

The DOE software's analysis showed that the most significant factors causing solvent pop were convection and infrared oven temperatures. Although there was significant interaction between both oven types, of the two, the convection oven was a bigger factor than the infrared. Refer to Figures 1 and 2.

By combining the correct oven temperatures, along with proper accelerator levels and activator types, we were able to consistently minimize solvent pop with acceptable film hardness and cure. The settings we obtained from the DOE software to minimize solvent pop are:

1.Low convection heat (Factor A-).

2.Low infrared heat (Factor B-).

3.High catalyst or accelerator.

4.Activator B.

By simulating our client's curing oven factors in a laboratory DOE, we optimized the settings that reduce solvent pop. Our client can now expect fewer application problems and higher production efficiencies.

Related Content

Henry Ford Is Still Right When It Comes to Color

Who would have imagined that more than 100 years after his famous statement about any color as long as it’s black would still have relevance of a sort?

Read MoreSurface Prep Solution for Rusted Rebar in Concrete

Julie Holmquist of Cortec Corporation discusses passivating corrosion on rebar and other reinforcing metals.

Read MoreConcrete Reinforced Bars Built to Last

Not all corrosion-resistant materials for infrastructure are created equally. Epoxy-coated steel rebar has advantages that other materials used to prevent corrosion do not.

Read MoreCuring Oven Basics

Simply heating up the substrate does not cure the coating. There are many variables to consider when choosing the best cure oven for your application...

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreEducation Bringing Cleaning to Machining

Debuting new speakers and cleaning technology content during this half-day workshop co-located with IMTS 2024.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read More

.jpg;maxWidth=300;quality=90)