Reading a Type II Dry Film Thickness Gage

Q: What should I look for when comparing gages? Testing and measurement expert Rob Weber from Fischer Technology provides this answer.

Q. I’m confused about Type II dry film thickness (DFT) gage specifications. Some manufacturers show an accuracy specification and some a trueness specification. Some show the gage repeatability, others do not. What is more

important: accuracy, repeatability or trueness? What should I look for when comparing gages?

A. That’s a very good question, because terms such as accuracy, precision, repeatability, trueness and so on are often misunderstood, interchanged or used incorrectly. Each of those criteria is important in understanding a gage’s true performance. When looking to compare different gage solutions it’s important to understand what those criteria mean.

ISO 5725-1:1994 is an excellent resource to gain additional information on this topic. This standard goes into great depth on the subject, but I will distill it here:

- Accuracy – the closeness of agreement between a test result and the accepted reference value.

- Precision – the closeness of agreement between independent test results obtained under stipulated conditions.

- Repeatability – precision under repeatability conditions, conditions where independent test results are obtained with the same method on identical test items in the same laboratory by the same operator using the same equipment within short intervals of time.

- Trueness – the closeness of agreement between the arithmetic mean of a large number of test results and the true or accepted reference value.

(Reference: ISO 5725-1:1994 Accuracy (trueness and precision) of measurement methods and results — Part 1: General principles and definitions)

In other words:

- Accuracy – how close a measurement is to the real (or accepted) value.

- Precision – how close together measurements are within a group.

- Repeatability – consistency between groups of measurements measured the same way, on the same part, by the same person.

- Trueness – the closeness of the average of a large number of measurements to the actual, or true, value.

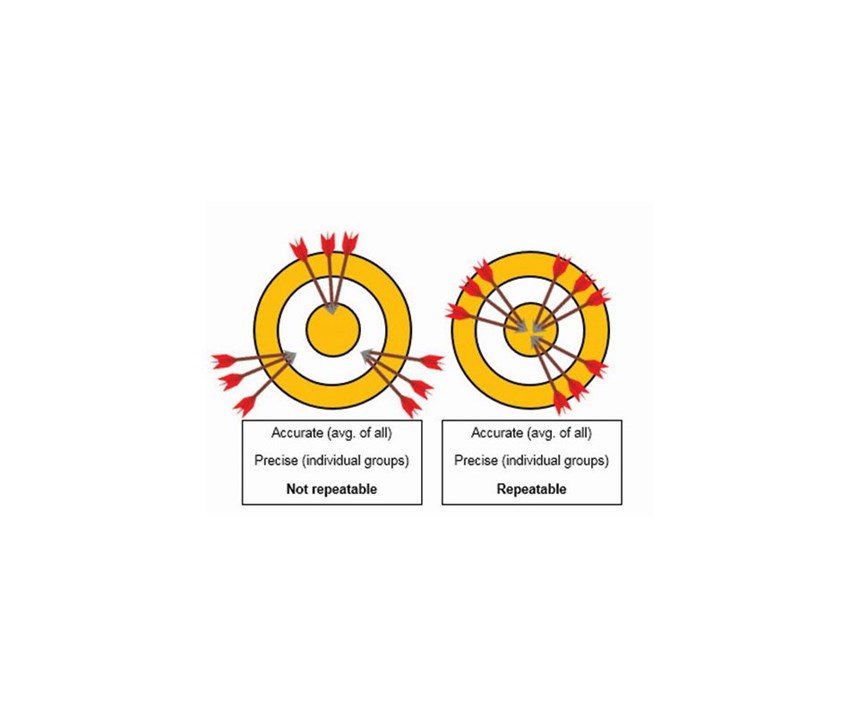

Graphic analogies can be helpful to describe this visually. Something else to consider to ensure accurate measurement is the quality of the calibration standards used for field adjustment and gage verification. With DFT gages, you’ll often hear the terms calibration “foils” or “shims.” These are typically plastic, polymer or metallic standards labeled with thickness values.

It is important to consider the quality, or tolerance, of the calibration (adjustment) standards used with the gage. The tolerance of the standards needs to be included in the measurement value. In other words, the most capable gage available, calibrated and adjusted to standards with a tolerance of ±20 percent, can only be considered to be accurate to ±20 percent.

Where and how does this affect the user of a DFT gage? For example, a project theoretically requires 50 gallons of paint to meet a minimum dry film thickness of 5.0 mils. Using ±20 percent calibration standards, the contractor must apply the coating to a thickness of 6.0 mils to compensate for the standard’s tolerance and meet the specification’s minimum true thickness of 5.0 mils. Using standards with a ±5 percent tolerance enables the contractor to coat closer to the true required thickness, only needing to apply the coating to 5.25 mils to meet the 5.0 mil minimum thickness requirement.

| Gage A (using ±20% standards) |

Gage B (using ±5% standards) |

|

| Paint to a true thickness of 5.0 mil |

60 gallons (5.0 mil + 20%) |

53 gallons (5.0 mil + 5%) |

| Cost of paint | $4,500 | $3,975 |

| Savings from simply using better standards? $525 | ||

Another consideration for calibration standards is to look for not only the tolerances, but also for traceability of the standard. Is the calibration standard traceable to an accredited laboratory? Standards, traceable to a recognized organization, are helpful in demonstrating and proving a measurement device is working correctly and providing trustworthy readings.

The bottom line, or the moral, for this is story is to look beyond a simple “accuracy” specification and also look to a gage’s trueness and repeatability specifications as important criteria in comparing measurement systems. Another factor in measurement performance is the quality, tolerance and traceability of the corrective calibration standards used for gage adjustment.

About the Author

Robert Weber

Rob is an applications and product support engineer with Fischer Technology. Visit fischer-technology.com.

Related Content

Corrosion Resistance Testing for Powder Coating

Salt spray can be useful to help compare different pretreatment methods and coatings but it does not tell us much about the corrosion resistance of a part over time in the field. Powder coating expert Rodger Talbert offers insights into how to get a better idea of how to improve a part’s corrosion resistance in the real world.

Read MoreAttention to Measurement

English vs. Metric — which should you use? Ron Kinne of Haviland Enterprises Inc. explains why you need a firm understanding of both for measuring various aspects of plating processes.

Read MoreShedding Light on Surface Inspection

State-of-the-art reflector-based lighting system improves luminosity and ergonomics for surface inspection tasks while reducing energy usage.

Read MoreSUR/FIN 2023: Capsules from the Technical Sessions I: Emerging Technologies

SUR/FIN 2023 in Cleveland this past June was a resounding success. Due to the efforts of the Technical Activities Committee, ably led by Bill Nebiolo this year, an outstanding program of technical presentations was offered. What follows are summaries of selected presentations from the Emerging Technologies sessions. Additional coverage will be provided in this space in the coming months. The full report can be accessed and printed at short.pfonline.com/NASF23Aug1.

Read MoreRead Next

Delivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreEpisode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read More