Trimac’s Mobile System Provides Powder Coating on the Go

The Mini-Mobile system opens the powder coating process to many types of users, from job shops and manufacturing cells to laboratories, universities and even hobbyists. Users can plug it in and be curing parts in under five minutes.

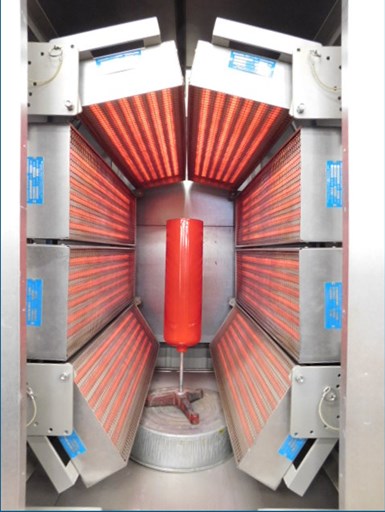

Trimac Industrial Systems, a Kansas-based producer of infrared ovens, washers and custom finishing systems, has developed a small, nearly portable powder coating system, the Mini-Mobile. The Mini-Mobile system comprises a powder coating booth as well as a curing oven, and its compact footprint makes it applicable to operations of many sizes. The company claims it is the only system of its kind on the market.

Marty Sawyer, CEO and owner of Trimac, says the idea for the Mini-Mobile system was first conceived after the company acquired Protherm Electric Infrared in 2017 — an acquisition that apparently made Trimac the sole producer of convection, gas catalytic infrared and electric infrared ovens in North America. Protherm had a small, conveyorized show oven that Sawyer thought would be good to showcase at an upcoming FABTECH display. At the conference, the oven turned out to be a hit, and Sawyer says, “I realized there was a product here.” The company would spend the next few years workshopping the system into the Mini-Mobile.

The Mini-Mobile is a modular system that comes in a standard size (20" × 20" flat part or 12" cube; max part size of 12" × 18" × 20") and large size (40" × 40" flat part or 24" cube; max part size of 28" × 36" × 36"), and Trimac also offers custom sizes. The oven has three heaters on each side which can be moved, tilted and adjusted based on the needs of the finishing job. The system, which is emission free, is designed to finish small parts about the size of a cell phone.

A system with such a small footprint opens the powder coating process to many types of users, from job shops and manufacturing cells to laboratories, universities and even hobbyists. The Mini-Mobile is a great solution for job shops that need to rework parts or produce a small run of custom orders without having to do a color change in their main operation. Sawyer also highlights the oven as being conducive to learning in an educational setting, saying, “One of the great things about infrared is that you get to see the curing process — you can watch the product gel right in front of your eyes.” Sawyer adds that as she explains the process in-person, she has noticed people become “mesmerized as they see the powder go from matte to glossy, and they begin to better understand the process.”

The company’s design philosophy with the Mini-Mobile oven is all about reduction: smaller footprint, smaller utilities and less time on the line. The company claims that users can plug the system in and be curing parts in under five minutes. In this way, the system brings lean manufacturing concepts to the powder coating industry. Sawyer adds, “The idea is that you can powder coat at the end of the operation without transporting the part to another location, another building, much less another state.” The Mini-Mobile system is available to order now and is set to start shipping at the beginning of next year.

Trimac Industrial Systems | 800-830-5112 | trimacsystems.com

Related Content

12 Ways to Improve Your Powder Coating Quality

Often overlooked powder coating procedures that can help you elevate your quality, streamline your operations and improve your profitability.

Read MoreProducts Finishing Reveals 2024 Qualifying Top Shops

PF reveals the qualifying shops in its annual Top Shops Benchmarking Survey — a program designed to offer shops insights into their overall performance in the industry.

Read MoreConveyors and Paint Systems

Choosing the right conveyor system, coating technology, and ancillary equipment.

Read MorePowder Coating 4.0: Smarter, Faster, More Efficient and Connected

New tools reduce cost and waste, lower manufacturing footprint of powder coating operations.

Read MoreRead Next

Episode 45: An Interview with Chandler Mancuso, MacDermid Envio Solutions

Chandler Mancuso, technical director with MacDermid Envio discusses updating your wastewater treatment system and implementing materials recycling solutions to increase efficiencies, control costs and reduce environmental impact.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreDelivering Increased Benefits to Greenhouse Films

Baystar's Borstar technology is helping customers deliver better, more reliable production methods to greenhouse agriculture.

Read More

.jpg;maxWidth=300;quality=90)