Uyemura Showcases Silver Parts Protection

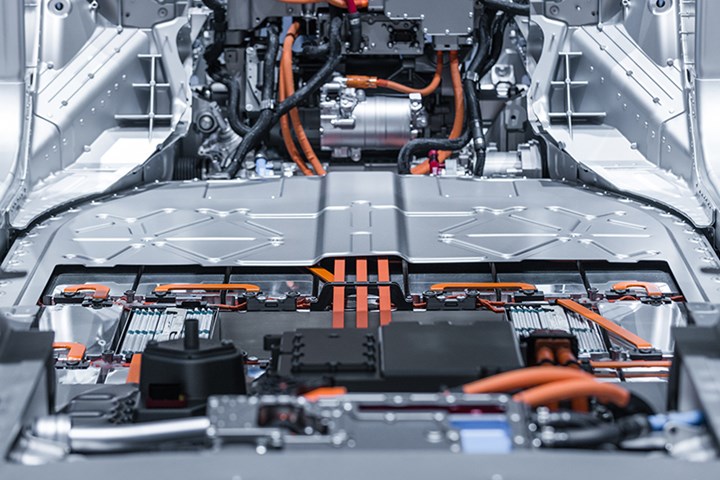

Photo Credit: Uyemura Uyemura’s silver protection features inorganic anti-tarnish that withstands high heat and voltages without compromise of contact resistance, resistivity or solderability.

Uyemura’s silver protection features inorganic anti-tarnish that withstands high heat and voltages without compromise of contact resistance, resistivity or solderability. Silver parts, particularly automotive electronic components, are protected from tarnishing/discoloration by a thin, transparent layer. Topseal 693 is proven on connectors used in charging systems, large buses, similar applications. In addtion, it does not require electrolytic enhancement.

Also featured in Uyemura’s booth will be sealing 691/692, for long-term protection for gold, silver, copper and tin. It is said to permanently preserve brightness on jewelry, handles and decorative components, and it also seals thin gold’s inherent porosity.

According to Uyemura, a few nanometers deposit is specified; applying current builds layers many molecules thick. The company says it has substantial advantages for electronic applications.

Uyemura USA | 860-793-4011 | www.uyemura.com | Booth 314

Related Content

-

Development of a Novel Hexavalent-Chromium-Free Aluminum Sacrificial Paint

Hexavalent chromium is a known carcinogen, repro-toxin, and mutagen. Its elimination is of high importance to the aerospace industry, which has struggled to find high performing alternatives. Legacy aluminum sacrificial paints have traditionally utilized hexavalent chromium to prevent corrosion and coatings which are equal to or better than have been difficult. This first paper discusses the novel process from the supplier point-of-view.

-

Tin-Zinc Alloy Electroplating and Its Corrosion Behavior

An NASF/AESF Foundation Research Program Retrospective

-

SUR/FIN 2023: Capsules from the Technical Sessions I: Emerging Technologies

SUR/FIN 2023 in Cleveland this past June was a resounding success. Due to the efforts of the Technical Activities Committee, ably led by Bill Nebiolo this year, an outstanding program of technical presentations was offered. What follows are summaries of selected presentations from the Emerging Technologies sessions. Additional coverage will be provided in this space in the coming months. The full report can be accessed and printed at short.pfonline.com/NASF23Aug1.

.jpg;maxWidth=300;quality=90)