Published

Automotive Decorative Plating: A Photo Portfolio of the First Golden Age of Surface Finishing

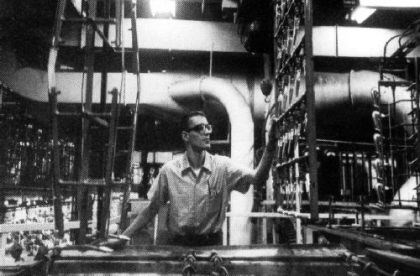

This is a series of scanned 35mm slides taken of 1950-60 era plating facilities.

by Dr. James H. Lindsay, AESF Fellow, NASF Technical Editor

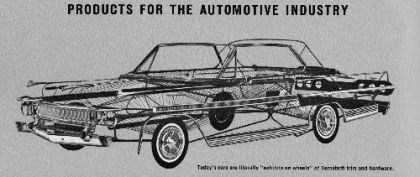

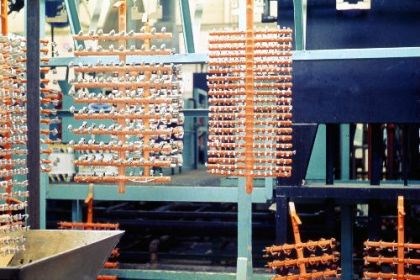

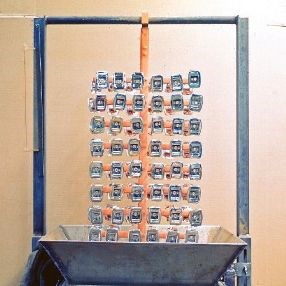

A half-century ago, decorative plating was coming into its heyday, with the automotive industry comprising its largest segment. The cars of that era were “dripping with chrome” and new technologies seemed to be emerging every week. Ever improving coating systems and processes for multilayered copper-nickel-chromium were advancing apace. The output of area plated could be expressed in terms of square miles per year, as the engineers designed and developed the machines and processes to manufacture the millions of grilles, bumpers and other automotive body hardware that was the essence of the automobiles of that time.

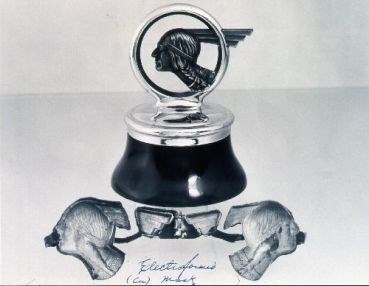

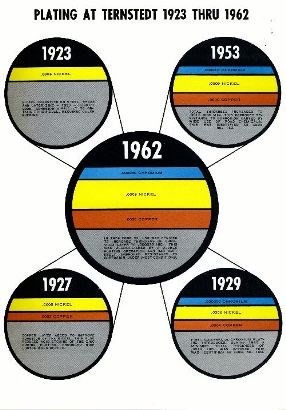

In North America, the automakers (many more than the big three at the time) did almost everything in-house, including plating. Within General Motors, the Ternstedt Division was responsible for producing much of the plated automotive body hardware, grilles, emblems, wheel covers, door handles, and on and on. Its original claim to fame was the manufacture of window regulator mechanisms, beginning in the 1920s. The Ternstedt Division had six plants (and briefly a seventh) at Detroit and Flint, Mich.; Columbus and Elyria, Ohio; Trenton, N.J.; and Syracuse, N.Y. At the time, Ternstedt was said to contain the largest plating facilities in the world.

The Ternstedt Division was one of many pioneers in the field of decorative plating. Along with Ford, Chrysler, other General Motors Divisions and other automobile companies consigned to history, the industry sought automotive hardware that provided a bright finish appealing to the customer, and corrosion durability that would keep the car looking new for years to come.

None of this could have been done without the suppliers, whose research and development efforts provided the plating processes to meet the needs of the automobile industry. Of course these finishes were not just limited to the automobile, as applications as diverse as marine hardware and furniture all benefited from these technologies.

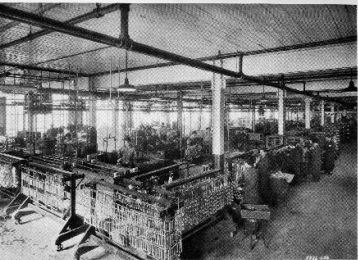

Today, these plating facilities have been dismantled, and the plants have either been demolished or converted to other uses. What follows, then, is a portfolio of photographs, taken decades ago, which preserve a look at the plating facilities at the Ternstedt plants. The facilities are there, warts, encrusted plating salts and all. While many of the engineering details in these photos are lost to history, they provide a look at what many consider to be the golden age of automotive decorative plating.

Automotive decorative plating began much earlier than mid-century, as shown by the photo of the plating department at the Ternstedt-Detroit plant, taken in 1926:

Related Content

-

The 2024 Ford Mustang: All the Colors Available

Although Chevrolet has announced the end of the Camaro and Dodge is offering “Last Call” editions of the Charger and Challenger, the Ford Mustang is launching to its seventh generation.

-

Titrations: To Automate or Not to Automate?

What considerations should you keep in mind for automatic titrations? Conor McAnespie of Hanna Instruments discusses the benefits of auto titrators.

-

Enhanced Functionality, Commercial Viability

Nano-particle additives modify coating performance to protect sensitive electronic devices.